- europages

- >

- Food industry - machinery and equipment

- >

- AVITEQ VIBRATIONSTECHNIK GMBH

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

Manufacturer/ Producer

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

The AViTEQ Hopper discharge unit is used below hoppers, silos, bunkers or bulk containers for flowable bulk materials and serves as a combined closure, discharge, transportation and metering device. It is used where high material flows are required. Short hopper discharge units are mounted directly below the bulk hopper. Depending on the bulk material, the discharge unit can be fitted with appropriate protective linear and sealing systems. Advantages & benefits robust design and therefore long-lasting variable feeding speed with magnetic vibrator for optimal dosing to the process bunker closure without additional barriers arrangment central below the bunker run, simple and professional installation possible upon request, in a dust-tight design to save the environment Construction The main components are: conveyor bunker shoe for product guiding inside the feeder drive elastic support elements optional: flexible sealings optional: needle or blade gate for closing Selection The s

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-trough conveyor are suitable for conveying and metering of pourable bulk material up to almost any particle size. By ensuring robust and open, trough-shaped structure are particularly suitable conveyors in extreme environmental conditions, because of the easy cleaning ability, but also happy in the chemical and food industry. Advantages & benefits Wide range of applications: using magnetic vibrator drive(s) or vibrator(s) dust-proof versions available long conveying inserted through serial connection possible multiple drive possible execution in mild steel or stainless steel Construction Conveyors are characterized by their simple design. The main components are: conveyor with drive traverse drive in-/outlet pipe (covered variants) elastic support elements flexible seals Selection The sizing is dependent on: bulk material throughput required geometry possible installation mass Key figures length: up to 9,000 mm on single units, theoretically unlimited for conveyor lines

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

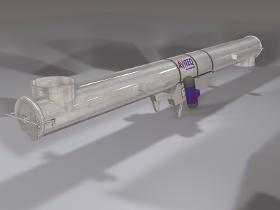

AViTEQ-Tubular feeders are suitable for handling and dosing of free flowing bulk material with a max. grain size of 1/3 of the tube diameter. Especially when the conveying process has to be dust free, tubular feeders are suitable through their closed design; which is needed also with high standards of hygiene and cleanliness. For feeding poisonous and hazardous substances, tube conveyors are used preferred. Advantages & benefits Wide range of applications: dustproof food suitable construction driven by magnetic vibrator/s or unbalanced motor/s long distances possible due to serial connection of feeders possible (conveyor lines) multiple drive possible (magnetic vibrators) variants available for reversing machines separate replacement of tube body or drive traverse (clamp version) made of mild steel or stainless steel Construction Tube feeders are characterized by their simple design. The main components are: feeding tube with a drive beam, either welded or connected by clamping s

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

Discharging, feeding, conveying AViTEQ reversing conveyors are used wherever bulk solids have to be conveyed and metered in an opposing direction. They are executed as reversing conveyor troughs or pipes. AViTEQ reversing conveyors are used primarily in the food and chemicals industries. Customised solutions, however, can also be realised for the recycling and raw materials industry.The technology used in the magnetic vibrator enables precise metering and exhibits no disruptive start-up or discharge behaviour. Advantages & Benefits mechanical flap and deflection systems eliminated (e.g. Y-fitting) considerably reduced installation height and hence cost saving through lower building costs reversing conveyors also act as shut-off devices the use of magnetic vibrators creates certain benefits (controllability, metering accuracy, no wearing parts etc.) reversing conveyors are available in ATEX design Construction The main components are: reversing conveyors from various materials (e

Request for a quoteSince 1939, AViTEQ has provided top-quality reliable solutions for vibration conveyor and process technology for a wide range of industry sectors and has always been ready to help via its global service.

Website

Manufacturer/ Producer

Im Gotthelf 16

65795 Hattersheim - Germany

Company info

Key figures

-

- Company headcount

- 51 – 100

Organisation

-

- Year established

- 1939

-

- pages.epage-home.site-status

- Registered office – Parent company

-

- Main activity

- Manufacturer/ Producer

Activities of AVITEQ VIBRATIONSTECHNIK GMBH

- Food industry - machinery and equipment

- Sand and gravel

- Motor vibrators

- Goods handling systems, continuous

- Heat exchangers

- Vibratory feeder

- Screening machines, screening plants and screening equipment

- Sieving machines

- vibrating sieves

- measuring systems