- europages

- >

- Ceramics- refractory

- >

- XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

- >

- Alumina Direct Bond Copper DBC Ceramic Substrate

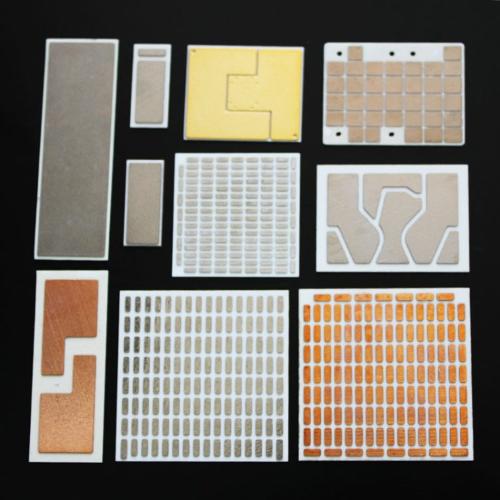

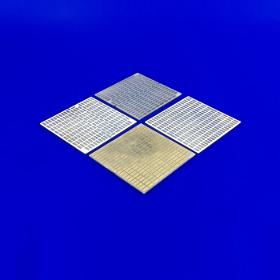

Alumina Direct Bond Copper DBC Ceramic Substrate

0.25mm 0.28mm 0.45mm 0.5mm 0.635mm 1.0mm 1.5mm 1.8mm 2.0mm

Description

DBC ceramic substrate: Direct bonded copper (DBC) substrates are commonly used in power modules, because of their very good thermal conductivity. They are composed of a ceramic tile (commonly alumina) with a sheet of copper bonded to one or both sides by a high-temperature oxidation process (the copper and substrate are heated to a carefully controlled temperature in an atmosphere of nitrogen containing about 30 ppm of oxygen; under these conditions, a copper-oxygen eutectic forms which bonds successfully both to copper and the oxides used as substrates). The top copper layer can be preformed prior to firing or chemically etched using printed circuit board technology to form an electrical circuit, while the bottom copper layer is usually kept plain. The substrate is attached to a heat spreader by soldering the bottom copper layer to it. 1. Thickness of substrate can be thin: 0.25mm,0.28mm,0.45mm,0.5mm,0.635mm,1.0mm,1.5mm, 1.8mm,2.0mm 2.

- Ceramics, refractory

- Metallized Ceramic Substrate

- DBC Ceramic Substrate

- Direct Bond Copper Substrate

Product characteristics

- Thickness

- 0.25mm,0.28mm,0.45mm,0.5mm,0.635mm,1.0mm,1.5mm, 1.8mm,2.0mm

- Density:

- 3.3-3.7

- Thermal Conductivity:

- 170

Similar products from XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

DBC (Direct Bonded Copper) tenique denotes a special process in which the copper foil and the al2o3 or AlN (one or both sides) are directly bonded under appropriate high temperature. The finished super-thin DBC substrate has excellent electrical isolation,high thermal conductivity, fine solderability and high bonding strength.It may be structured just lick PCB to get etched wiring and has high curreng loading capability .Therefore DBC ceramic substrates have become the base material of tuture for both the construction and the interconnection techniques of high power semiconductor electronic circuits and also have been the basis for "chip on boaed" technology which repre-sents the packaging trend in century. Specification >Metallization thickness: 25 ±10um >Nickel thickness:2~10um >Pin full strength: 4200kgf/cm2 avg. (at Φ3.0mm pin)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

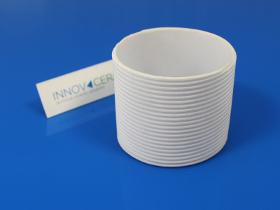

Alumina ceramic (Aluminum Oxide or Al2O3) is an excellent electrical insulator and one of the most widely used advanced ceramic materials. In addition, it is extremely resistant to wear and corrosion and is an industrial ceramic that can only be formed by diamond grinding. The melting point is very high at 2,072°C, and it is very hard. Alumina components can be widely used in electronics, pump components and automotive sensors.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA is good at yttria stabilized zirconia. Unlike other ceramic materials, zirconia is a material with very high resistance to crack propagation. Zirconium oxide ceramics also have very high thermal expansion and are therefore often the material of choice for joining ceramic and steel. > high fracture toughness > thermal expansion similar to cast iron > extremely high bending strength and tensile strength > high resistance to wear and to corrosion > low thermal conductivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Typically ceramic bolt and screws are used in low-stress & high temperature conditions. These conditions are most commonly found in electronic equipment, where ceramic screws are particularly attractive due to their lack of electrical conductivity. Another benefit of ceramic screws over polymer based ones are that they have much higher and longer lasting performance due to their ability to withstand sustained heat cycling. Supply in M2x5, M3x10 and M4x10 screws with nuts, customized size is acceptable.We recommend to use the screws only together with the supplied nuts. The usage with metallic threads might not fit as the ceramic parts are manufactured in moulds and reach their final dimension after sintering. Hence they have other tolerances than metallic threads. >Thread Specification:M3-M24 >Screw cap:Hexagonal socket, flat head >Plain Ceramic Hex M3 x 10mm Set Screw >Made from alumina ceramic >Suitable replacement for plastic screws to solve embrittlement or creepage problems

Request for a quote