BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Manufacturer/ Producer

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

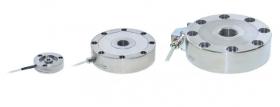

The 8524 precision tension & compression load cell is a versatile sensor for highly accurate load measurements in diverse applications. Optimum measurement quality is achieved with the load cell mounted on a flat, hard and polished contact surface. This requirement does not apply to small measurement ranges of up to 0 ... 2 kN because three knife-edge bearings ensure that the sensor is seated securely. Our brochure „Load Cells“ explains how you can design parasitic loads out of your mechanical system. Through-holes in the outer flange are used for fastening the 8524 sensor to the system structure. The load is applied via the central blind threaded hole or optionally via a load button. Alternatively, a pull plate and even rod end bearings, if desired, can be attached to the sensor for equally easy measurement of purely tensile loads, for instance in Bowden cables or chains. The 8524 sensor is designed to measure static, quasi-static and dynamic compressive and/or tensile loads.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The load cell measures the compression forces between the circular contact surfaces of plunger and tool. The pin on its top side and hole on its lower face are simply provided for mechanical fixing and centering the components correctly. To provide as large a range of mechanical compatibility as possible, the pins/holes are available in different diameters. Attachments are available which clamp onto the press sensors to enable easy mounting of displacement sensors according to the circumstances of use. FEATURES: — Measuring ranges from 0 … 100 N up to 0 … 25 kN — Small, compact design — Pin/hole diameter from 8 mm to 16 mm — Different diameter for pin and hole can be combined — Mechanical overload protection for all measurement ranges

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Thanks to its compact shape and three fixing holes on its underside, the 8526 compression load cell can be used in a variety of applications. With its wide choice of measuring ranges from 0 ... 100 N up to 0 ... 1 MN, it really can cover a wealth of measurement tasks, from the laboratory to use in heavy industry. The integral load button provides an easy and reliable means of applying the force to be measured. Angle errors in the load application with a deviation from the measurement axis of up to 3° have only a minor influence on the measurement signal. For ideal measurement accuracy, the load cell should be mounted on a surface that has been ground and has a hardness of at least 60 HRC. The model 8526 load cell is designed with an internal elastic membrane, to which strain gages are attached. When a compressive load is applied to the load cell, the membrane is elastically deformed and transfers its tension to the strain gages.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The tension & compression load cells from the 8523 series are designed for a wide range of uses. The sensors feature many benefits, including three point-contact mounts for tilt-free installation. Thanks to this feature, excellent measurement results can be achieved even with a sub-optimum mounting surface. The force to be measured is applied to the central threaded hole in the tension or compression direction. For measuring purely compressive loads, using load buttons from our accessories range saves the need for complex sensor-integration mechanisms. Tensile loads in rods or chains can also be detected with ease using the optional pull plate. Inside the sensor is an elastic membrane, on which are applied strain gages connected in a full Wheatstone bridge. FEATURES Measuring ranges from 0 ... 20 N to 0 ... 5 kN Tilt-free installation thanks to point-contact mounts Excellent price/performance ratio Easy mounting burster TEDS optionally available

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This force measurement chain was developed for applications where a low cost solution is more important than achieving high levels of accuracy. The sensors strain gauge technology allows the measurement of static and dynamic forces. The load cell is also designed for applications that provide only little space due to its compact design. These properties, together with the sensors dust protection, make the measuring chain suitable for a wide range of applications, such as Industrial manufacture Manufacture of customized machinery Geological investigations Motor vehicle engineering Commercial agriculture Bridge building The body of the sensor is a flat, cylindrical disk, into which a domed force application knob is integrated. It is important that the force is applied axially to the center of the sensor. The domed form, however, minimizes the effect of a force that is not exactly axial.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high precision torque sensor is designed for both static and dynamic measurements on non-rotating applications. It is particularly suitable for torque measurements on, for instance, extremely small electrical actuating drives and micro-mechanical actuator elements, or for measuring reaction torques e.g. on micro-motors. The high accuracy of measurement also makes this sensor ideal for use as a reference in many fields of industrial manufacture as well as laboratory research and development projects. Not containing any rotating parts, it requires no maintenance if properly used. The strain-gage based sensor’s modular design allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ±10 V that is proportional to the torque. The sensor can be configured via the micro-USB interface, providing access to, for example, a filter frequency setting, averaging, and a tare function.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This torque sensor is qualified for static and dynamic measurements on non-rotary applications. Further the measurement of reaction torques on rotating machine parts is possible. Especially the torque sensors with flanges are preferred. They are mounted between motor and stator, e.g. in agitator drives. This enables a maintenancefree torque measurement. For individual measuring tasks the design of our torque sensors can be adapted to the customer’s installation conditions. More application examples: Test structures in the field of precision mechanics Determination of friction torques Acquisition of breakage moments on screw caps The design has been optimized regarding overall length, weight and volume, so that axial forces up to relatively high limit values and bending moments of up to 20 % of the measuring range have only a small effect to the influence of the measuring element.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 8661 precision torque sensor is the ideal choice for reliable measurement of static and dynamic clockwise and counter-clockwise torques. Thanks to its high measurement quality and low linearity error, the sensor is equally at home in quality control or research & development. Designed for non-contact operation and zero-maintenance, the 8661 is also ideally suited to the production environment, whether on shift-based production lines, test benches or end-of-line test systems. The 8661 torque sensor is the specialist device for constant torque measurements during continuous operation and for test-bench measurements of holding, friction, break-away or tightening torques. An optional built-in incremental encoder disk with up to 2000 increments makes the sensor the perfect alternative where space or budget rule out an additional angle or speed sensor. For mobile use and for instant digital access to measurement data, the 8661 torque sensor is also available with a USB interface.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Precise, reliable measurements of both static and dynamic torques in either direction can be made with this range of sensors. This opens a wide range of possible applications to the user. These torque sensors are standard equipment in a wide range of industrial automation, quality control and automotive components industry applications, as well as in laboratories. Typical applications: Screwing technology — Checking and adjusting bolting tools such as torque limiting wrenches, screwdrivers — Testing bolted connections Measuring the drag torque of motors and pumps — Frictional torques of gears, bearings and seals — Testing torsion springs — Adjusting equipment in the automobile industry (sunroof, power windows etc.) Strain gauges are mounted on the torsion shaft of the sensor element, itself made of steel, connected to form a full bridge.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Inductive displacement sensors of this series measure linear displacements and indirectly all mechanical values convertible into displacements by additional equipment (i.e. tension and compression forces, extension, torque, vibration). The sensor body equipped with a connector has an outer diameter of only 8 mm and therefore is especially well suitable for the integration in dimensionally restricted structures. Typical application fields are displacement and extension measurements on: —Machines —Servo systems —Motor vehicles —Test benches —Production plants The cylindrical case made of stainless steel, houses a differential transformer (LVDT). It consists of a primary and two secondary coils with axially moveable core. A displacement of this core changes the magnetic induction of the coils. The INLINE carrier frequency amplifier converts the displacement into a direct proportional electrical DC voltage.

Request for a quoteManufacturer/ Producer

Talstraße 1-5

76593 Gernsbach - Germany