- europages

- >

- Steel & Metals

- >

- AMETEK SPECIALTY METAL PRODUCTS

- >

- Beryllium Copper 25 Alloy

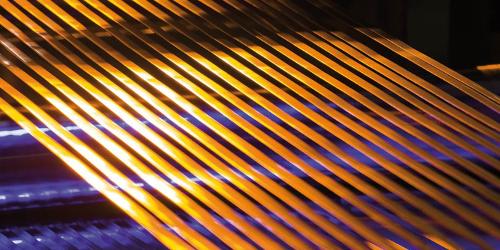

Beryllium Copper 25 Alloy

Copper base alloy, precipitation heat treatment, mechanical strength alloy

Description

Beryllium Copper 25 is a Copper base alloy with the capability of being strengthened by precipitation heat treatment. The alloy furnishes the best combination of electrical conductivity, corrosion resistance and mechanical strength necessary for numerous electronic and electromechanical devices. The alloy is quite satisfactory for fabrication with good formability and joining characteristics. Forming is readily accomplished from the annealed temper. Severe bending will be less successful from hard or heat treated tempers and requires large fold radius ratios. Beryllium Copper 25 is able to be soldered, brazed, and welded by most standard techniques. The brazing temperature must be kept under 1450º F and cycle time minimized to avoid loss of heat treated strength. Heat treating should be performed subsequent to welding to obtain uniform high strength. The alloy is not susceptible to an increase in magnetic attraction from plastic deformation during service

- Steel & Metals

- Copper base alloy strip/foil

- ni strip and foil

- nickel alloy strip and foil

Product characteristics

- Density

- 0.298 lbs./cu.in.

- Melting Point (Approx.)

- 865°C

- Electrical Resistivity @ R.T.

- 7.81Microhm·cm

- Thermal Expansion Coefficient (20° to 200°C)

- 17.5 x 10-6/°C

- Thermal Conductivity @ R.T.

- 105 W/m·K

- Magnetic Attraction

- None

Similar products

OREMUS S.R.O.

Czech Rep.

Our four-cylinder rolling machines offer a maximum width of 1900 mm, and pipe twisting up to a diameter of 220mm at max. 6mm gage. In smaller versions 1000mm, for diameter min. 125mm

Request for a quote

PERGEL METAL

Turkey

Lux serial server cabinets are high density. It is used for cable and data center need. Since it has a fairly low cost, it is often preferred. Since it is a network cabinet system, it will work for your plans for the future. Cable options are quite well developed. Fiber and cable management is good. If you are in need of high cable management, we will help you with this. In addition to making the capacity of the cable wider, it also provides ease of installation and use. It also makes its maintenance much simpler. It offers a wide range of products and a wide variety of accessories. It is especially very important to save money. It provides an advantage in terms of transportation cost and warehouse space.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free