- europages

- >

- Printed circuits

- >

- DK CERAMIC CIRCUITS

- >

- Ceramic PCB

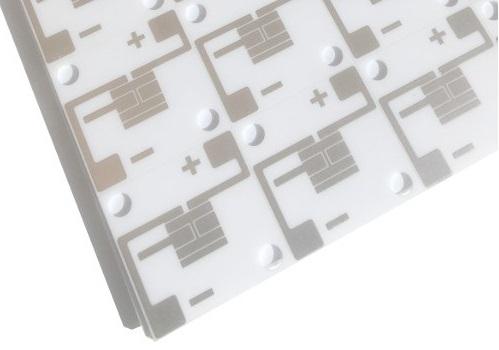

Ceramic PCB

CTE matching with high thermal conductivity

Description

When you are looking for substrates for electronic circuits with a high thermal conductivity and a low expansion coefficient (CTE), ceramic pcb will be your preferred choice of material. Today ceramics are already widely used as substrates in many microelectronic components and power LED packages and more and more they are replacing entire printed circuit boards reducing complexity in design and manufacturing while increasing performance. Examples are Chip-on-board (COB) modules, High power circuits, proximity sensors, battery drivers for EVs, … .

- Printed circuits

- ceramic pcb

- ceramic circuits

- thermal PCB

Product characteristics

- Category

- Thickfilm Thickfilm, LTCC

- Conductor material

- Ag/PdAg Ag/PdAg

- OG (Glass coating)

- Transparent / Black Transparent / Black

- Max # Layers

- 10 10

- Substrate Color

- Grey White, Black

- Panel Size

- 110mmx110mm 120mmx120mm standard (180mmx180mm possible)

- Panel size tolerance

- ±50um ±50um

- Thickness per layer

- 0.25, 0.36 or 0.5mm 0.1, 0.25, 0.38, 0.5, 0.635, 0.8 or 1.0mm

- Thickness tolerance

- ±5% ±5%

- Warpage (non-flatness)

- ≦±0.2% ≦±0.2%

- Surface Roughness

- 0.3~0.6 μm

- Warpage

- ≦0.3 %

- Thermal

- ppm/°C Coefficient of Thermal Expansion (CTE)

- Coefficient of Thermal Expansion (CTE) RT~500 °C

- 6.82 ppm/°C

- Thermal Conductivity (25°C)

- 22 W/m‧K

Similar products

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Processing Technology: Electrolytic Foil Base Material: Copper Insulation Materials: Epoxy Resin Certification: UL, RoHS, ISO9001, Ts16949 Transport Package: by Vacuum Packing in Cartons Specification: UL, ROHS, SGS Origin:China HS Code: 85340090 Min. Order: 100 Pieces Port: China Production Capacity:100000 Square Meters Per Month Payment Terms: L/C, T/T, D/P Type: Rigid Circuit Board Dielectric:FR-4 Material: Fiberglass Epoxy Application: Consumer Electronics Flame Retardant Properties: V0 Mechanical Rigid: Rigid

Request for a quote

BERATRONIC GMBH

Germany

Technical data •Max. Panel size up to 1500mm x 670mm •PCB thickness from 0.1-17.5mm •Smallest hole 0.075mm •Smallest trace/spacing 50µm •Copper layer up to 1000µm •Number of layers up to 58 •Aspect Ratio 20:1 •Rigid flex and flex •Viaplugging •Impedance control •Laser Microvias •Blind, Buried Vias Basic material •FR4, FR4 High TG, FR4 •halogen-free, CEM1/3, Rogers, •Ceramic (Al2O3), polyimide and others Surface •HAL lead-free, HAL Pb/Sn, chem. Ni/Au (ENIG), chem. Ni/Pd/Au (ENEPIG), chem. Sn, chem. Ag, OSP(Entek), galv. Ni/Au, Carbon, Ag/Pt (thick film technology) and others Solder resist and placement printing •Different paint systems (including halogen-free) and colors Standards •ISO 9001:2015 / IATF 16949 •UL listing •RoHS / REACH •Manufacturing according to IPC A600 class 2 and 3 Delivery times •Rush service from 1 AT •Series from 10 AT Data preparation •Legacy document preparation •Scan Service •Data conversion •CAM data preparation •CAD layout service

Request for a quote

DAMEKS

Poland

PCB depanelization is a process step in the production of large-scale assembly of electronics. To increase the throughput of printed circuit board (PCB) and surface mount (SMT) production lines, printed circuit boards are often designed to consist of many smaller individual printed circuit boards that will be used in the final product. This PCB cluster is called a panel or multi-block. The large panel is broken or "depanellated" as a process step - depending on the product, this can be right after the SMT process, after the in-circuit test (ICT), after soldering through-hole components, and even just before the final assembly of the PCBA in the enclosure.

Request for a quote

DISTRIBUCIONES JULMARSA S.L.

Spain

Designed to meet the needs of smaller, high performance electronic circuitry. These new gap fillers provide an outstanding heat transfer interface across a range of component heights with minimal compression force. THESE PRODUCTS ALL PROVIDE: • Range of thicknesses from 20 mils to 250 mils • Intrinsically tacky surfaces for excellent self-adhesion • Available with various surfaces (no-stick, fabric) for specific application needs • UL 94 V-0 flame retardancy • Large 24" x 24" sheet sizes for improved die-cutting yield with custom sizes available • Range of compliance and thermal conductivities to fit specific applications

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free