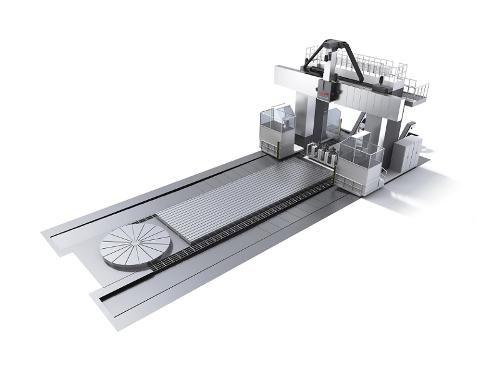

Droop+rein G/gf

Description

How can large, heavyduty and bulky workpieces be processed without adversely affecting the weight and size of the machining result? The Droop+Rein G/GF series has been specifically developed to tackle this difficult task. The gantry machines reliably prevent dynamic losses through the table and workpiece. The G/GF series has many technical highlights to meet the requirements of complex machining tasks, such as the hydrostatic guide in all linear axes or the thermosymmetrical design of the spool milling unit with an integrated Caxis. Milling heads can be changed automatically via a head change interface. Droop+Rein has developed over 300 different milling heads for a variety of applications such as machining large diesel engines. The option to set up in a second working area during the machining time allows increased productivity.

- Machine tools, metal machining - parts and accessories

- Droop Rein

- Machining Center

- Machining Hydrostatic

Product characteristics

- Power (100% DC)

- kW 50 - 150

- Torque

- Nm 2,400 - 10,000

- Speed

- rpm 2,500 - 6,000

- Length

- mm from 8,000 + 1,000 mm steps

- Width

- mm 3,000 - 12,000 (+ 500 mm steps)

- X-axis

- mm 8,000 - 30,000 (+ 1,000 mm steps)

- Y-axis

- mm 3,000 - 13,000 (+ 500 mm steps)

- Z-axis

- mm 1,500 - 4,000

- W-axis

- mm 1,000 - 5,000 + 500 mm steps (only for G)

- C-axis

- ° ± 180/n x 360

- X-axis

- m/min 20

- Y-axis

- m/min 20

- Z-axis

- m/min 20

- W-axis

- m/min 4 (only for G)

- C-axis

- °/min 3,600

Similar products

NINGBO FRIMA INDUSTRY CO. LTD.

China

Specifications: Product name: precision machining parts Material: aluminum, steel, brass ,plastic, carbon steel, nylon, PP Dimensions: according to customer’s drawing Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc. Packing: PE bag, carton, wooden box Processing equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc. Service project: To provide production design, production and technical service, mould development and processing, etc. Testing machine: Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on. Minimum order quantity: 1000pcs Delivery: 7-30 days Business scope: CNC center machining, drilling, turning, grinding, tapping, mould design and processing, casting, sheet mental working etc.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Whether lathe or machining center Complete machining made easy: You cannot only use our MANDO and MAXXOS segmented mandrels on the lathe, you can also use them in stationary mode. Simply screw the mandrel onto the ms dock [manually actuated] or hs dock [hydraulically actuated] and you can clamp your workpiece from the inside, stationary mode. Precise, without vibration and with minimum set-up effort. The extremely wear-resistant segmented clamping bushing of case-hardened chromium-nickel-steel with the rubber between the segments, especially developed by HAINBUCH, makes it possible. Hydraulic actuating unit hs dock hs dock is an absolute powerhouse that enables hydraulic implementation of MANDO and MAXXOS segmented mandrels on machining centers. Media supply can be freely selected. It is actuated either from the side or via a base plate from below. Perfect when automation is involved.

Request for a quote

PRESSTA EISELE GMBH

Germany

4 axis CNC floor-type vertical spindle machining center. 4 axis (X, Y, Z, A) managed by CNC. By means of dedicated tools it’s suitable for working on 5 sides of aluminium, PVC and steel sections. The work pieces are held by means of 4 pneumatic vices on the mobile beam, that can be positioned on any angle between +125° and -125°. The rotation is directly managed by the control cycle. It offers a high programming functional capacity by using a three-dimensional graphics software. Electro-welded base designed to grant maximum rigidity and functional capacity of use. The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The vices slide on ball recirculation screws, and can be positioned manually by referring to a mm-scale and a laser pointer. By using the disc cutter it is possible to carry out end-milling operations on both the ends of the work piece (end-milling cycle). Milling operations can be performed with...

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free