- europages

- >

- Mechanical transmission - components

- >

- ARNOLD UMFORMTECHNIK GMBH & CO. KG

- >

- Thread-rolling fastener for metals

Thread-rolling fastener for metals

Fastener for joining metals with low tapping torque / TAPTITE 2000®

Description

Using TAPTITE 2000® ensures that in metal-joining applications, you can eliminate work processes such as tapping and the use of additional fastening elements. The fastener is screwed straight into a cast or drilled core hole. The polygonal cross-section geometry of the shaft of the screw ensures that the thread is chiplessly formed, so that if a repair is needed it can accept a conventional threaded screw. This provides some significant quality advantages: easy to position the screw low tapping torque high vibration resistance high vibration resistance high pre-load forces high assembly reliability Your commercial benefits: The overall cost of fastenings is reduced by up to 88%.

- Mechanical transmission - components

- Thread-rolling

- thread-tapping

- screw

Product characteristics

- Feature (1)

- easy to position the screw

- Feature (2)

- low tapping torque

- Feature (3)

- high vibration resistance

- Feature (4)

- high pre-load forces

- Feature (5)

- high assembly reliability

Documents

Videos

Similar products

OTTO EICHHOFF GMBH & CO. KG

Germany

PT screws for thermoplastics: Thread rolling screws for direct screwing into plastics, Thread 30° or 60° KTG screws for thermoplastics: Single-start or double-start thread (high, low) Thread rolling screws are extruded for larger batch sizes and turned for small batch sizes (Turned parts for direct screwing) High tensile and highly stressable connection of thermoplastics with considerably longer life endurance Thread rolling without chips and loss of material Minimum radial tension, large thread coverage Process-reliable due to torsion strength Shorter and slimmer screws are possible. Materials: Steel, case-hardened Quenched and tempered steel 1.5523 tempered to 1000 +200 N/mm², high-grade steel 1.4567, other materials on request Length: 3 – 160 mm (at lengths from 60 mm only partial thread lengths 4 x d are possible) Thread diameter: 1.6 – 10 mm Special dimensions on request Batch sizes: Standard ex-stores Special screws from 30,000 pieces

Request for a quote

MPS MICRO PRECISION SYSTEMS AG

Switzerland

MPS Microsystems offers a complete range of high precision ball screws for positioning less than 5 µm. Mostly custom-made, these screws ensure smooth and uniform movement resulting from the high precision of their thread, achieved by grinding. Our ball screws are made exclusively of stainless steel and are fitted with double nuts to allow fine adjustment of the axial play. Moreover, an optional ogival thread can provide a higher static and dynamic load capacity. Thanks to a large number of options, we can ensure that the ball screw meets your technical and quality needs. The following parameters can be personalized: lubricant (grease, oil, dry lubrication, no lubrication), customized screw ends, shape and external dimensions of the nut and screw, multiple nuts on the same screw, left-hand thread, thread length, specific axial play, special surface treatment, and more.

Request for a quote

NORELEM FRANCE

France

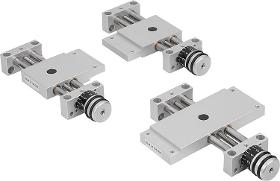

Bearing block and carriage aluminium alloy, anodised. Guide columns stainless steel, ground. Spindle stainless steel, rolled thread. Guide bearing maintenancefree. Version Radial play on guide < 0.02 mm. No axial backlash. Spindle selflocking, with additional lock. Note The almost playfree guides and absolutely playfree spindle allow for adjustment without the need to loosen or clamp the spindle. The scale graduation is in 5 or 10 increments; 1 increment corresponds to 0.1 mm of travel. The cross stage can be easily combined with positioning stages, vertical stages and other accessories of respective size by the modular principle.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free