ZUMBACH ELECTRONIC AG

Switzerland

Manufacturer/ Producer

ZUMBACH ELECTRONIC AG

Switzerland

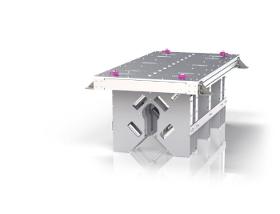

Thanks to the robust, dirt-resistant design of the Steelmaster, it is suitable for hot steel applications under production conditions with a lot of dirt and warm product and ambient temperatures. Properties Cutting-edge optics and laser scan technology Extremely high sampling rate Highest accuracy and stability; measurements independent of orientation Non-contact measurement of diameter and ovality Suitable for measurements under harsh conditions Interfaces such as Ethernet IP, Profinet IO, Profibus DP and others Integrated web server in all processor versions. Benefits High operational reliability even under harsh conditions Heat resistant, thanks to integrated heat shield and water cooling Protective system using air purging unit and blower Very robust and durable design Extremely dirt resistant.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

Measuring solution suitable for quality control and inspection of tube samples The Gauge Pro is suited for laboratory use, for example for inspecting the following samples: Medical hoses Cosmetics tubes Heat-shrink tubes Rubber hose Small tubes and hoses Properties For testing samples Measuring of outer diameter, inner diameter and wall thickness Creation of reports and batch statistics Possibility to integrate databases Standard 4-point measurement; up to 8 points depending on recipe selection and workpiece rotation Benefits Sample preparation is less critical Easy desk solution All measurements are completed in fewer than 2 steps Options for single part or batch measurement.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

The CAPAC HS measuring system measures the coaxial capacitance of plastic-sheathed conductors with high accuracy during the production process. The measuring system is used wherever precise knowledge of the core capacitance is a decisive quality feature, such as in the production of fully and cellular PE-insulated inner conductors for HF and CATV cables as well as in the extrusion of data and LAN cables (Cat. 5, 6, 7, 8). It is also suitable for measuring products with a capacitance (conductor in combination with insulation), to check for fault sources. For example analysis of a corrugated metal pipe with insulation. For accessories and detailed product information, refer to the respective brochures at our website with the following link: https://zumbach.com/products/capac/

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

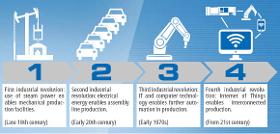

These days, everyone's talking about Industry 4.0. Are we facing something unknown or unheard-of? In actual fact, the technologies involved in Industry 4.0 are well-known; the concepts are visionary but not new. Much ado about nothing? Interconnecting physical objects with the virtual world using modern technology produces new working methods and business models that, set against current trends, are more evolutionary than revolutionary. The momentum surrounding Industry 4.0, however, should not be underestimated. Equipping components and machinery with sensors and software makes it possible to acquire field data automatically. Interconnection means this data can be retrieved in near real-time and collated at a central point. What could previously be seen directly at the components and machinery on the shop floor can now be visualised and monitored using software on a single platform. The result is maximum transparency. All data is provided at application level, making it easy to...

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

The BENDCHECK system is suitable for in-line production optimization in the steel and metal industry. The measuring solution enables in-line quality assurance in the production of tubes and rods and eliminates the need for complex manual straightness measurements. Properties: Synchronous real-time scan to monitor bending of the product 3 to 5 non-contact measuring stations with 1 to 3 measuring axes Direct integration into the existing production process Constant quality assurance, also after the straightening process Recording of statistics, ensuring traceability Time savings thanks to automatic measurement control Continuous measurement without slowing down the production process Replaces manual measurements by means of off-line stations Optional measurement of head and tail bending with additional measuring stations. Benefits: Cutting-edge optics & laser scan technology Maximum accuracy & stability Extremely high sampling rate Comprehensive quality control

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

Continuous surface inspection for all kind of products ZUMBACH's all-new SIMAC 40/70 is fulfilling today’s needs for in-line surface inspection of extruded products like pipes, cables and hoses with the consistent implementation of machine vision and machine learning. Defect detection The SIMAC detects anomalies and material defects that are difficult to detect, such as compounds that are not fully crystallised, burnt material inclusions, missing coatings, scratches, ridges, colour defects, bubbles, cracks, holes, etc. Main Features • Continuous in-line surface inspection • The 4 cameras ensure 100% coverage even for small product thanks to overlapping zones. • Advanced algorithms search in the image for defects based on pre-trained examples. • Quick and easy introduction into production lines with the opening on the side • Compact design allows easy maintenance • Works with all surfaces/colors • Data recording for later analysis and defect detector training.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

Laser measuring device for measuring diameter, ovality, circularity, width and height of round products and profiles Properties Cutting-edge optics and laser scan technology Maximum accuracy and stability Orientation-independent measurement Non-contact measurement of diameter and ovality Identification of lumps and neckdowns Extremely high sampling rate Permanently calibrated Integrated interfaces such as Ethernet IP, Profinet IO, Profibus DP and others Integrated web server in all processor versions Benefits • Maximum precision thanks to laser scan measuring principle • Robust and durable design • Extremely dirt resistant • Comprehensive quality control • High operational reliability even under harsh conditions • Measurement of opaque or transparent products • Position measurement possible. For accessories & detailed product information, refer to respective brochures on the following link from our website: https://zumbach.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

Rugged and compact 7" capacitive Touch Screen. This universal PoE (Power over Ethernet) powered touch screen enables display of the integrated web interface of the connected ZUMBACH sensor device. Such as ODAC, ODEX and MSD diameter and ovality gauges, KW lump/neckdowns detectors, Spark Tester systems, RAYEX S systems among others. Devices without PoE can be powered via the separate 24V input connector. Advantages / Features • Reactive performance • Kiosk mode gives intuitive user friendliness • Hot pluggable with just 1 standard Ethernet cable • Up to 6 display characteristics – User definable • Set point and tolerance inputs with colour variation for fast indication of in or out of specification • Inbuilt terminal for extended device configuration/interrogation • Can be used as localized display or remote networked display • Base IP address can be re-configured to suit customized applications such as remote display within factory network.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

The processor is used for communication, analysis and display of sensor values for continuous transparency in processes such as: – Wire drawing – Extrusion procedures – In-line or off-line applications – Cutting – Drawing procedures – Tube forming and welding – Taping – Peeling – Centreless grinding – Stranding / assembling – Coating applications Properties Application for specific processor solutions available Processor for monitoring and controlling measuring values Statistical analysis and logging Product recipe management and storage Digital and analogue inputs and outputs Possibility to integrate several sensors Integrated standard host interface FFT/SRL analysis for maximum 4 parameters Zumbach RealTime operating software provides maximum virus protection thanks to embedded software solution.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

UMAC WALLMASTER systems from ZUMBACH allow in-line measurements, data acquisition and control during the extrusion of a wide range of products, like tubing, pipe, hoses and cables. Cutting edge digital technology (DSP) opens up measuring solutions for each process and product: • Ultra thin walls • Smallest and largest diameters • Multi-layer products • Cable isolations and jackets Special products requiring an off-line QC measurement can now be measured in-line and relevant parameters monitored continuously. The diameter can also be measured in a combination with the ultrasonic measurement with certain transducer holder. In addition, UMAC WALLMASTER systems provide for real-time QC data, process monitoring, trending, SPC data, statistical charts etc.

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

BOURDON HAENNI GMBH

Germany

Bourdon takes mechanical pressure monitoring into the digital age This innovative device fits to any comprehensive platform for machine and process monitoring as well as the preventive maintenance of equipment which is supported by a LoRa wireless protocol. Key applications include pressure measurement and monitoring for oil refineries, petrochemical industry and biodiesel plants. More predestined applications are in waste and water treatment, power generation and transmission, general process industry, building services and civil engineering. The right choice when industry grade wireless pressure measurement and monitoring is required

Request for a quote

MERECS ENGINEERING GMBH

Germany

We plan, build and deliver turnkey test systems for electronic and mechanical components. For example, these are test benches for quality assurance, validation and production departments of companies in various industries. Our services include e.g.: - Development test benches - Life time test benches - End-of-line test benches (production) - Retrofit of existing systems (software / hardware) - Climate & temperature test systems - Leakage test benches - Software development LabVIEW, TestStand, Python, C/C++ (Embedded), Microsoft PowerBI, SQL - Electronics development - Mechanical 3D CAD design - Risk assessment and CE - Commissioning, service, maintenance at home and abroad

Request for a quote

MERECS ENGINEERING GMBH

Germany

EOL test stand for e-charging columns and their power electronics for the simulation of different electrical loads and mains fluctuations. The test stand has automatic contacting and achieves high test throughputs in end-of-line operation. Different variants of the power electronics of electric charging columns can be tested. On the software side, Merecs Engineering relies on NI-LabVIEW and NI-TestStand.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free