- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- load cells

Results for

Load cells - Import export

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Due to their small dimensions and sturdy construction, these miniature compression load cells made of stainless steel can be used in a wide range of industrial applications and in laboratories. This compression load cell is easy to handle and its installation is uncomplicated. Its small size makes it perfect for use in very restricted structures for both static and dynamic compression force measurements. The miniature compression load cell model 8415 is a flat cylindrical disc, the bottom of which is closed with a cover. The load application button for receiving the compression forces is an integrated part of the sensor. A strain gage full bridge is applied in the gauging member of the measuring element. This produces bridge output voltage directly proportional to the measured force. The small diameter of the sensors results in high rigidity and a short measurement range. The measuring force has to be applied centrically and free from lateral forces.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Due to their extremely compact design, these load cells can be used wherever static or dynamic load forces have to be measured in very tight spaces. Model 8416 is perfect for use in micro-technology and just as suitable for measuring tasks in the research and development sector. The ultra-miniature compression load cell model 8416 is a flat, circular disc, the bottom of which is sealed with a cover. The load application button for receiving the compression forces is an integrated part of the sensor. The sensor element inside the body carries a strain gage full bridge which outputs voltage directly proportional to the measurement variable upon application of force. The short nominal measurement distance of the ultra-miniature compression load cells due to their design provides a high degree of rigidity. If needed, the nominal characteristic value can be standardized in the sensor connection cable.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Load cell model 8417 measures the tension or compression force between both axially mounted metric exterior threads on the cylindrical sensor housing. Forces are only applied to the threadings, which are especially long, to accommodate counter nuts and must not be affected by external influences such as bending, lateral force or torsion. Any contact with units affixed to the sensor housing - even on the front - must be avoided. The measurement element is a membrane perpendicular to the axis of the sensor with a strain gage full bridge applied to the inner surface, which requires stable excitation with a rated value of approx. 1 mV/V. The connection cable is led radially out of the housing through a sleeve which is used for strain relief. FEATURES: —Measuring ranges from 0 ... 10 N to 0 ... 5 kN —Very small dimensions —Made of stainless steel —Rugged construction —Simple screw mounting —burster TEDS optionally available

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

These models are among our most precise and yet mechanically robust miniature load cells. High accuracy, finely graded measuring ranges, small dimensions and the simple introduction of force via opposing threaded pins open up a wide scope of laboratory and production applications. Their sophisticated engineering with integrated support membranes and overload protection reduces additional design expense in many applications, e.g. for external overload protection or guiding the parts introducing force to the cell. The result is that less space is required, less material is used and less weight is involved. Last but not least, there is hardly any friction on components that could falsify the measurement result. The force to be measured is introduced centrally and axially to the cylindrical sensor body in the tension or compression direction by means of the two threaded pins. This requires the sensor to be mounted without any elements touching the end faces of the sensor housing.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This, related to its measuring range, miniaturized load cell enables an universal and reliable operation in industries and laboratories. It is well suited for compression measurements in very restricted structures. The load cell is a compact construction and made of superrefined steel. Therefore it can be used in many fields of industry, like. Examples are: — Press-in force measurements on longitudinal and transversal connections — Compression force measurements on punch and roller applicancy — Spring tension measurements on shock absorbers for cars — Contact pressure determination in push rods — Compression force measurements on compressed-air knee-lever presses Thanks to the rounded top, in shape of a little hat, the force to be measured is led into the sensor centrically and free of lateral force. Specific characteristics: Very small dimensions Drug chain qualified cable Made of stainless steel burster TEDS optionally available

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The force to be measured must be introduced axially and perpendicularly to the entire surface of the inner and outer bands of the sensor in the opposite direction. Conversion of the acting force into an electrical output signal is performed by strain gages connected together in a full bridge circuit. To achieve optimal accuracy, the base of the sensor should rest on a smooth level surface, hardened to at least ≥ 58 HRC with sufficient dimensions. The base cover welded to the surface has a stabilizing effect on the sensor element. Lateral forces must be avoided anyway as they distort the measured results. Tension and bending relief for the sensor cable is to be carried out on the machine side. FEATURES: — Measuring ranges from 0 ... 100 N to 0 ... 200 kN — Centric throughout hole — Flat disc design — Made of stainless steel — Completely welded sensor body — Nominal characteristic value standardization possible — burster TEDS optionally available

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The measuring element of the load cell consists of a double bending beam on which strain gages are applied. The applied force detunes the measuring bridge so that a proportional output voltage is generated. The strain gages on the measuring element are protected against dirt and water spray by a rubber bellows. The sensor can be easily mounted via two mounting holes. The tension or compression force to be measured is introduced at the opposite end perpendicular to the sensor axis. Due to its special design, the influence by an extension (e.g. touch finger) on the measuring signal is low. Overload protection can be realized with little effort using a mechanical stop. FEATURES For tension and compression forces Measuring ranges from 0 ... 5 N to 0 ... 2 kN Relative non-linearity: ≤ ±0.1 % F.S. Very low mounting height Simple force application Material aluminium or stainless steel Special design on request burster TEDS optionally available

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This miniature force sensor was optimised with respect to its height and is, at only 3.4 mm, the lowest known sensor with strain gage technology. Hardly higher than the diameter of its connection cable, it can also be housed in conditions where space is limited. Along with its minimal geometry, the force sensor is also particularly light. It has a high resonance frequency to follow quickly changing load alternations. Despite its extreme miniaturisation, in its application it remains completely robust and suitable for industry, not only with regard to the highly flexible cable connections or the full welding of sensors for the measurement ranges ≥ 0 … 10 N. The miniature compression force sensors are flat, cylindrical discs with covered bottoms. The central load application button for taking on compression forces is an integrated part of the top, which is the sensor‘s membrane.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The sensor element consists of a double bending beam with applied strain gages. Changes in the ohmic resistance of the strain gage fullbridge caused by applied forces are converted into electrical voltages. The precise value (characteristic value) of the output voltage, resulting from the application of a rated force to the sensor, is specified in the accompanying calibration protocol. The sensor has to be mounted by two screws on the cable side. The opposite side is meant to receive applied forces (loads). Once the rated stress or strain is exceeded by 20 %, further deflection of the bending beam is prevented by an integrated, mechanical stop. This protects the sensor element against permanent deformation.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The tension and compression load cell model 8435 enables universal and fast installation, requires hardly any installation space and upgrades with technical data that are readily achieved by larger sensors. Due to its excellent price-performance ratio with regard to its mechanical and electrical data, the force sensor finds its place in products that are also manufactured in larger quantities and calculated with a small budget. This model of load cell uses proven strain gage technology to perform measurements. Strain gages are applied to the sensitive element and connected to form a full bridge. FEATURES Measuring ranges from 0 ... 200 N up to 0 ... 5000 N Small dimensions Inexpensive execution Stable anti-kink protection Made of high quality stainless steel Connecting cable suitable for drag chains burster TEDS optionally available

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The tension & compression load cells from the 8523 series are designed for a wide range of uses. The sensors feature many benefits, including three point-contact mounts for tilt-free installation. Thanks to this feature, excellent measurement results can be achieved even with a sub-optimum mounting surface. The force to be measured is applied to the central threaded hole in the tension or compression direction. For measuring purely compressive loads, using load buttons from our accessories range saves the need for complex sensor-integration mechanisms. Tensile loads in rods or chains can also be detected with ease using the optional pull plate. Inside the sensor is an elastic membrane, on which are applied strain gages connected in a full Wheatstone bridge. FEATURES Measuring ranges from 0 ... 20 N to 0 ... 5 kN Tilt-free installation thanks to point-contact mounts Excellent price/performance ratio Easy mounting burster TEDS optionally available

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

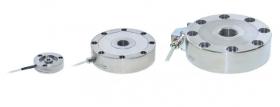

Thanks to its compact shape and three fixing holes on its underside, the 8526 compression load cell can be used in a variety of applications. With its wide choice of measuring ranges from 0 ... 100 N up to 0 ... 1 MN, it really can cover a wealth of measurement tasks, from the laboratory to use in heavy industry. The integral load button provides an easy and reliable means of applying the force to be measured. Angle errors in the load application with a deviation from the measurement axis of up to 3° have only a minor influence on the measurement signal. For ideal measurement accuracy, the load cell should be mounted on a surface that has been ground and has a hardness of at least 60 HRC. The model 8526 load cell is designed with an internal elastic membrane, to which strain gages are attached. When a compressive load is applied to the load cell, the membrane is elastically deformed and transfers its tension to the strain gages.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The load cell measures the compression forces between the circular contact surfaces of plunger and tool. The pin on its top side and hole on its lower face are simply provided for mechanical fixing and centering the components correctly. To provide as large a range of mechanical compatibility as possible, the pins/holes are available in different diameters. Attachments are available which clamp onto the press sensors to enable easy mounting of displacement sensors according to the circumstances of use. FEATURES: — Measuring ranges from 0 … 100 N up to 0 … 25 kN — Small, compact design — Pin/hole diameter from 8 mm to 16 mm — Different diameter for pin and hole can be combined — Mechanical overload protection for all measurement ranges

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 8524 precision tension & compression load cell is a versatile sensor for highly accurate load measurements in diverse applications. Optimum measurement quality is achieved with the load cell mounted on a flat, hard and polished contact surface. This requirement does not apply to small measurement ranges of up to 0 ... 2 kN because three knife-edge bearings ensure that the sensor is seated securely. Our brochure „Load Cells“ explains how you can design parasitic loads out of your mechanical system. Through-holes in the outer flange are used for fastening the 8524 sensor to the system structure. The load is applied via the central blind threaded hole or optionally via a load button. Alternatively, a pull plate and even rod end bearings, if desired, can be attached to the sensor for equally easy measurement of purely tensile loads, for instance in Bowden cables or chains. The 8524 sensor is designed to measure static, quasi-static and dynamic compressive and/or tensile loads.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The model 8527 high-precision compression load cell is the ideal load cell for reference measurement chains where highly precise measurement results are required. Its very high production quality and extremely low non-linearity of just 0.035 % F.S. make it a dependable choice for comparative measurements and calibration tasks. Designed for a dynamic stress of up to 100 % of the full scale value, the model 8527 load cell is also suitable for situations where a rapid signal change with high amplitude occurs and has to be measured. The model 8527 high-precision compression load cell has a domed load button on top, onto which the compressive load being measured is applied. Inside the load cell is an elastic membrane, on which strain gages generate a resistance change in the measuring bridge and an output signal proportional to the load. For the best possible measurement results, the force should be applied axially and centrically to the load button.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Inside the multi-component force transducer are two webs, each offset by 90°, each with a strain gage full bridge, which convert the radially acting X / Y forces on the guide bush into an electrical signal. Due to the sensor body made from a block with its special structure, the sensor has a very high degree of dimensional accuracy and low crosstalk between the two forces. Due to the special design, the sensor has excellent linearity properties and is designed for a long service life in dynamic applications. The two independent signal connections allow flexible adaptation and further processing. Features: — Measuring ranges: 0 ... 4448 N / 0 ... 2224 N (0 ... 1000 lbs / 0 ... 500 lbs); 0 ... 8896 N / 0 ... 4448 N (0 ... 2000 lbs / 0 ... 1000 lbs) — Further measuring ranges on request — Non-linearity < 0.1 % F.S. — Low cross talk < 0.75 % F.S. — High dimensional accuracy, because sensor is made from one part — Excellent price/performance ratio

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

With its flat construction this force sensor is specially designed to be fitted to a pedal. By this, the operator's forces for each respective action, for example brake tests, can be measured directly and the reaction of the vehicle or machine can be designated. This applies to real test drives, as well as in driving simulators. Due to the special construction of the membrane, it is irrelevant whether an upright or hanging pedal is concerned. The sensor is designed in a way that unavoidable lateral forces have as little impact on the measurement result as possible. Using a central internal thread on the control surface, various machine-related adaptor parts can be easily mounted. Because the pedal is convex-shaped on its surface, the pedal force sensor has a very rigid base plate and therefore can easily be applied to various geometrics. The mounting can even take place on a pedal with an elastomer covering.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The measuring element of this load cell consists of a double bending beam with strain gauges, the resistance of which changes with the application of force. Upon applying a voltage to the strain gauge bridge, the change in the strain gauge resistance is converted into output voltage, which is directly proportional to the force. The strain gauges and the entire measuring element are protected from water spray by metal cover including sealing material. The tensile or compressive load to be measured is applied to the sensor element through the M6 threaded hole located on each end face. The load can be applied easily, along the sensor axis. This serves to prevent falsification of the measured values. Overload protection can be realized with little effort using a mechanical stop. FEATURES Measuring ranges from 0 … 20 N to 0 … 880 N Relative non-linearity: ±0.25 % F.S. Many load cycles Protection class IP54 Excellent price-performance ratio burster TEDS optionally available

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The force measuring chain is an universal reference measuring chain for the calibration of press-fit force measuring equipment. It finds applications in the quality assurance, commissioning and equipment monitoring fields. A DAkks calibration certificate is included so that the force measuring chain can be traced back. The calibration is traceable through accreditation at the German Accreditation Body. The calibration certificate records the displayed values for mounting positions at 0°, 120° and 240°. During calibration in field, the reference load cell is inserted in line with the flux of the press-fit measuring equipment. The force application is of central significance here for the quality of the measurement. Special force application parts are required, so that the line of action of the force agrees as exactly as possible with the geometrical axis of the load cell that is to be measured (central loading).

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The Load cell model 8451 has been developed for measuring the forces that occur during press operation. The internal measuring elements have a rugged design, which mean they can cope reliably with the steep force curves that are typical of press applications. They can be fitted or replaced quickly and easily on the press ram without the need for additional components around them. The force sensor is placed between the tool and the press ram and can thus measure the actual compression force directly in the axis of operation. The load cell measures the compression forces between the circular contact surfaces of plunger and tool. The pin on its top side and hole on its lower face are simply provided for mechanical fixing and centering the components correctly. The connecting cables are suitable for drag chains, designed for many movements and stably fastened in the sensor housing.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Product Introduction: load cells are available in the capacities from 5kg to 500kg. Alloy steel & stainless steel construction construction with single shear beam type. Sealed welding ,waterproof, anti-corrosion and suitable for all kinds of environment. Integral structure and easy installation. Suitable for electronic platform scale, hopper scales and other electronic weighing devices. Features: Capacity :5kg to 500kg Defend grade: IP67 & IP68 High accuracy. Alloy steel & stainless steel single shear beam Low profile and nice exterior

Request for a quote

MINEBEA INTEC GMBH

Germany

Ideal for installation in platform scales and integration into machines: with the BCL-A single point load cell, you rely on proven quality from a leading manufacturer of industrial weighing technology. Suitable for load ranges from 300 g to 4.5 kg and a platform size of up to 300 mm × 300 mm.

Request for a quote

MINEBEA INTEC GMBH

Germany

The MP 55 Platform Weigh Cell is made completely from stainless steel, is available in a load range from 11 kg to 200 kg and platform sizes up to 600 mm x 600 mm. It is specially designed for integration into beltweighers, counting scales and checkweighers. Protection class IP68, IP69K Full stainless steel construction Hermetically welded seal (IP68, IP69K) Platform size up to 600 mm x 600 mm Approved to OIML R60 Ex-Version available (MP55/...E) High Input Impedance Integrated Mounting spacer

Request for a quote

MINEBEA INTEC GMBH

Germany

The PR 6251 fill-level sensor is specially designed for basic weighing of silos and horizontal tanks. It meets all requirements for years of trouble-free operation without adjustment. For use in EX zones 1, 2, 20, 21, 22 and DIV 1. Ultra-flat load cell for low precision tank weighing as alternative to level sensors Load cell capacity range from 500 kg to 16 t Accuracy class: L (0.5 %) Corresponding mounting kit: PR 6051

Request for a quote

MINEBEA INTEC GMBH

Germany

Specially designed for tank and hopper weighing, hybrid scales and high-precision dosing systems. For use in EX zones 1, 2, 20, 21, 22 and FM DIV 1. Ultra-high precision load cell for batching applications Load cell capacity range from 100 kg to 3 t Accuracy class: D1 (0.04 %), C3 (0.015 %), C6 (0.008 %) Corresponding mounting kit: PR 6046

Request for a quote

MINEBEA INTEC GMBH

Germany

Cast stainless steel load cell for use in platform scales and for basic weighing of small to medium-sized containers. The load cell is available in threaded and T-end versions. IP67 protected.Available for use in EX-zones 1, 20, 21. For economic vessel weighing solutions Load cell capacity range from 91 kg to 2.268 t Accuracy class: 0.02 % Corresponding mounting kits

Request for a quote

MINEBEA INTEC GMBH

Germany

The MP 79/79T Bending Beam Weigh Cell is made from stainless steel and is available in a load range from 227 kg to 5099 kg. This weigh cell is specially designed for use in weighing platforms and simple hopper weighing applications. Protection class IP68, IP69K For economic vessel weighing solutions Hermetically welded IP68/IP69 Load cell capacity range from 227 kg to 5.099 kg Accuracy class: 0.02 % Corresponding mounting kits

Request for a quote

MINEBEA INTEC GMBH

Germany

The PR 6202 is the world's first load cell designed strictly in accordance with the hygienic design principles developed by the European Hygienic Engineering Design Group (EHEDG). Proven rocker-pin principle Easy corner adjustment by matched load cell output Full stainless steel construction Wide temperature range High overload capacity Resistant against vibrations Hermetically sealed, IP68 (depth of 1.5 m for 10,000 hrs.), IP69K Ex-version available (PR 6202/..E) W&M approval (acc. OIML R 60)

Request for a quote

MINEBEA INTEC GMBH

Germany

Suspended mounting can better compensate for vessel movements. — Reliable weighing thanks to high resolution and accuracy class — Accuracy class: N (0,03%) and C3 (0,025%) — Specially designed for suspended vessel scales — Versatile optional weighing electronics Design-in support from specialists

Request for a quoteResults for

Load cells - Import exportNumber of results

146 ProductsCountries

Company type

Category

- Weighing and dosing equipment (45)

- Sensors (35)

- Measurement and regulation equipment and instruments - pressure (20)

- Weight and mass - measurement and regulation instruments (14)

- Fuel cells (13)

- Calibration equipment (2)

- Dosing - machines and equipment (2)

- ELECTRIC EQUIPMENT (2)

- Automation - systems and equipment (1)

- Balancing machines and systems (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Frequency and tuning devices (1)

- Lifting equipment - accessories (1)

- Measurement and control instruments (1)

- Paper and cardboard manufacturing - machinery and equipment (1)

- Steels and metals - machining (1)

- Weighbridges (1)

- Welding, electric - equipment and supplies (1)

- Wood veneer - machinery and equipment (1)