- europages

- >

- Conveyor systems

- >

- ALWAYSE ENGINEERING LIMITED

ALWAYSE ENGINEERING LIMITED

United Kingdom

Manufacturer/ Producer

Product catalogue preview

ALWAYSE ENGINEERING LIMITED

United Kingdom

When loads need to be moved smoothly, precisely and with minimum effort in any direction, Alwayse Ball Transfer Units are the ideal solution. With the widest range in the world and over 75 years’ experience Alwayse Ball Transfer Units are used in applications throughout industry.

Request for a quote

ALWAYSE ENGINEERING LIMITED

United Kingdom

Used by the largest glass processors and material handling companies in the world. Their design ensures smooth movement and easy directional change of materials with delicate or polished surfaces.

Request for a quote

ALWAYSE ENGINEERING LIMITED

United Kingdom

We stock a wide range of Castors and Wheels and associated components for all types of mobile equipment. Our highly experienced sales team experts can assist with your technical enquiries including on site advice.

Request for a quote

ALWAYSE ENGINEERING LIMITED

United Kingdom

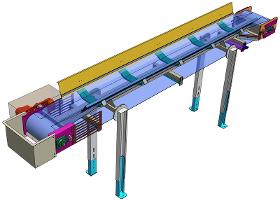

With low capital costs and virtually maintenance free, Gravity Rollers offer a cost effective alternative for hundreds of applications including the movement of materials, goods or packages. Rollers can be manufactured to your own specification, please contact our experts to discuss your individual requirements.

Request for a quoteALWAYSE Engineering was formed in 1939, and is today, the global market leading manufacturer of Ball Transfer Units. The original inventor of the Ball Transfer Unit, ALWAYSE currently employs more than 70 people at its purpose-built research, design and manufacturing facility based in Birmingham, UK. Over 70% of its production is exported to more than 60 countries worldwide, which led to Alwayse Engineering being awarded the Queen’s Award for Enterprise for International Trade on two occasions. Alwayse Ball Units & Castors are used in all major material handling industries by many of the world's biggest logistics brands throughout the world. Over 2 million units are manufactured and sold every year. Alwayse Engineering Limited is proud to be quality registered to ISO 9001.

Website

Documents

Manufacturer/ Producer

Miller Street

Aston

B6 4NF Birmingham - United Kingdom

Company info

Key figures

-

- Company headcount

- 51 – 100

Organisation

-

- Year established

- 1939

-

- pages.epage-home.site-status

- Registered office – Parent company

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- Regional

- National

- European

- International

Delivery areas

Activities of ALWAYSE ENGINEERING LIMITED

- Conveyor systems

- Ball Transfer Units

- Materials Handling

- Castors

- Rollers

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

FEMIA INDUSTRIE

France

According to your needs, transfers and/or elevates products to a machine located downstream. Can be adapted according to your needs and capacities. Increased reliability thanks to its stainless steel structure. Better preservation of the product thanks to its plates with or without plastic flights.

Request for a quote

FEMIA INDUSTRIE

France

Today, waste management has become a genuine challenge in sustainable development and yield on fruit and vegetable processing lines. Femia provides solutions aimed at extracting only the waste, without affecting the processing of good products. According to a model based on green and circular economy, they are then brought together, recovered and recycled.We design, along with you, a logic for customised waste recovery, according to your material recycling objectives (animal feed, farm use with or without composting), energy (methanisation) or incineration with energy recovery. We integrate the recovery approach right from the design phase for your production lines in order to allow your conveyors progressive and facilitated recovery of wastes all throughout theproduction lines.

Request for a quote

FEMIA INDUSTRIE

France

Provides the product transfer from a piece of equipment located upstream to a piece of equipment located downstream. Can be adapted according to your needs and capacities.

Request for a quote

FEMIA INDUSTRIE

France

Its unique, high performance design allows the full release of the smaller diameter green beans between the sorting bars. A very precise range of settings ensures product homogeneity, especially on extra fine sizes. The T43L and T46 models sort green beans into 2 sizes. The T44 model sorts in 2 3 sizes. For better user comfort, the T46 can be equipped with a remote adjustment system.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free