ANGSTROM SCIENCES, INC.

United States

Manufacturer/ Producer

ANGSTROM SCIENCES, INC.

United States

Angstrom Sciences' circular magnetrons have become recognized as the new standard of the sputtering industry, because in addition to the advanced features of the Angstrom Advantage™, they offer a host of other performance advantages as well. Versatile, Compact Design Their compact design makes our circular magnetrons ideal for any new or retrofit application, including the most complex cluster assemblies for the smallest vacuum chambers. Total Power Compatibility Low-impedence heads provide RF, DC, mid-frequency DC, pulsed DC, and microwave power compatibility.Circular Magnetron External Standard Fittings We use ISO NW standard fittings, as well as Conflat® metal seal flanges. All utilities are maintained at atmosphere and accessed through standard O-ring compression fittings for easy installation in any vacuum system. Full Range of Sizes Circular magnetron sources are available from 1" (25mm) through 16"(406mm) inch target diameters.

Request for a quote

ANGSTROM SCIENCES, INC.

United States

Advances in High Power Impulse Magnetron Sputtering (HIPIMS) or High Impact Power Magnetron Sputtering have long been pursued by modifying power supply systems that can deliver short bursts of power densities to a sputtering target. Angstrom Sciences has developed a series of circular sputtering cathodes capable of sustaining continuous power densities greater than 1500 Watts/in2. Angstrom Sciences’ high power pulsed magnetron sputtering cathodes incorporate two additional cooling channels in the anode body and stem tube to maintain optimum cooling during process operation. The magnetic arrangement within the HPP design is specially optimized for high power, magnetic applications. High Power Pulsed circular magnetrons are directly cooled and available in 4", 6", 8" and 10" outer diameters.

Request for a quote

ANGSTROM SCIENCES, INC.

United States

Angstrom Sciences offers state-of-the-art magnetrons for virtually any standard sputtering process. But we know that every application is different. That’s why we’ve developed a unique, modular approach that specifically adapts to your specifications. Cylindrical Magnetrons have long been trusted in the glass coating industry to create uniform thin films while maximizing target utilization. Now, Angstrom Sciences has created a compact, lightweight, and economical cylindrical magnetron specifically designed to offer these same advantages to Flat Panel Display, Solar Cell, and Web Coating applications. Custom Designs Complete assemblies are available from 3" to 6" in target diameter. Cylindrical Magnetron Side Mount Angstrom Economical and Fully-Compatible Investment The ONYX-Revolution™ utilizes a universal and cost-effective magnet design with customized turnarounds to fit any target type. And, it is designed with off-the-shelf components for low-cost, long-term investment.

Request for a quote

ANGSTROM SCIENCES, INC.

United States

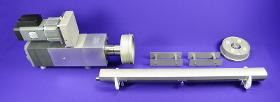

As more industries discover the speed, controllability, and bottom-line benefits of magnetron sputtering, Angstrom Sciences is developing tools to maximize the output of these larger, faster manufacturing processes. Broader Solutions For those who have to coat extremely broad substrates or have to achieve extremely high throughput, linear magnetrons offer the perfect solution. ONYX Linear Magnetron Patented Advantages Angstrom Sciences’ linear magnetrons incorporate our fully-encapsulated patented profiled NdFeB rare earth magnets and turbulent water flow to provide unparalleled performance. Standard Fittings We use ISO NW standard fittings, as well as Conflat® metal seal flanges. All utilities are maintained at atmosphere and accessed through standard O-ring compression fittings for easy installation in any vacuum system. Total Power Compatibility Low-impedance heads provide RF, DC, mid-frequency DC, pulsed DC, and microwave power compatibility.

Request for a quote

ANGSTROM SCIENCES, INC.

United States

Rotary magnetrons are variants of a circular magnetron where the magnet set is mechanically rotated about a central axis. This embodiment, originally developed for semiconductor applications allows for the uniform coating of a stationary substrate with the smallest possible cathode diameter. Other applications of this technology include situations where material re-deposited on the target face generates defects in the growing film; in a rotary magnetron the entire target face is swept clean by a magnet set rotating between 20 and 600 RPM. Angstrom Sciences offer a range of rotary magnetrons, from 4" (100mm) up to 16" (406mm) in diameter, and are designed with an adjustable magnet configuration allowing for process optimization and uniformity enhancement. Our magnetrons can be mounted in internal or external configurations. Rotary Magnetron Benefits A rotary magnetron offers excellent uniformity without movement of the substrate. This combined with full face erosion.

Request for a quote

ANGSTROM SCIENCES, INC.

United States

At Angstrom Sciences, we design, engineer and manufacture the world’s most advanced and reliable magnetron sputtering cathodes. And we stand by the quality of our products with the industry’s longest warranty on workmanship and materials - 2 years. We’re also committed to ensuring the highest quality performance throughout the lifetime of your magnetron. That is why we provide a comprehensive repair and rebuild service for any emergency or maintenance needs you may encounter on our ONYX® or other magnetron assemblies. Angstrom Sciences standard rebuild service includes: Source disassembly Mechanical and Electrical Damage Check Fit and tolerance inspection O-Ring replacement Screw replacement Total cleaning Magnet check: encapsulate, clean, and map Reassembly Testing: vacuum, electrical, and water (test sheet provided) Water and electrical line replacement (if necessary)

Request for a quote

ANGSTROM SCIENCES, INC.

United States

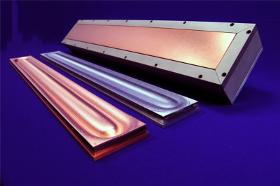

From sputtering targets to materials used for thermal/e-beam evaporation, Angstrom Sciences has the ability to suggest and direct the most suitable materials for any application. We draw from variety of specialized processing techniques such as Hot Pressing, Cold Pressing, Hot Isostatic Pressing (HIP), Cold Isostatic Pressing (CIP), Vacuum Induction Melting (VIM) and Vacuum Arc Casting to produce homogenous, fine-grained, high-density materials that conform to the strictest application standards. We routinely provide backing plates (copper, molybdenum, copper-chromium) for planar, circular and cylindrical sputtering targets, conductive pastes and thermal transfer foil for sputter target cooling, and also offer bonding services as part of our comprehensive range of services to the PVD community.

Request for a quoteManufacturer/ Producer

40 S Linden St

15110 Duquesne - United States

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Titanium sputtering targets integrated circuit information storage laser use Metal Fabrication Part

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free