- europages

- >

- Aerospace and aeronautics - construction

- >

- WESTLAKE PLASTICS EUROPE

- >

- Arolux PEKK: Thermoformable amorphous ketone thin sheets

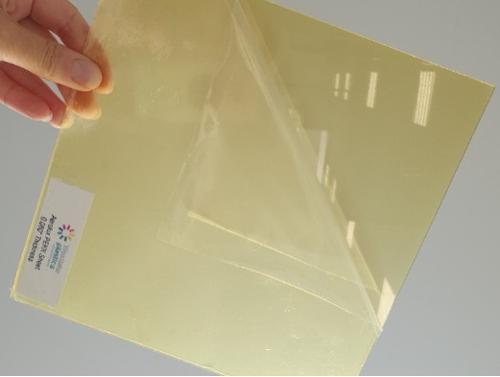

Arolux PEKK: Thermoformable amorphous ketone thin sheets

First amorphous thermoformable ketone material into semi-crystalline sheets/film

Description

An innovative techno-material combination for aero / defense / rail parts: With a resin manufacturing partner, Arkema, we have succeeded in extruding sheets in an amorphous state (PEKK material already qualified for aerospace) which crystallizes during thermoforming. The fact that the plates are amorphous allows thermoforming deformation and then crystallization offers all the thermal / mechanical / chemical properties of an ultra high performance polymer. Value proposition: advance in the replacement of metal parts / reduce process costs for machined PEEK parts / open the door to the manufacture of large parts (aircraft interior, drones, defense systems, railways, electrical boxes, ducting systems, etc. )

- Aerospace and aeronautics - construction

- thermoforming of plastic sheets

- vacuum thermoforming

- ducting systems

Product characteristics

- Density

- 1,29

- Glass Transition Temperature (Tg)

- 160-165°C

- Melting point

- 331°C

- Tensile strength (ISO 527-1BA)

- 110MPa

- Use Temperature

- 165 °C maintaining high mechanical resistance and > 240°C in continuous use

- Flammability rating

- UL94 V-0 / EN45545 R22/R23: HL3 (EU railway standard)

- Heat release rate FAR 25.853

- 43.52kW/m²

- Oxygen limit index

- 35-38 %O2

- Chemical resistance

- disinfectant / ethanol / MEK / Jet A fuel / toluene / LD-4 : all 1 week @ 23°C - no effect.