- europages

- >

- Bending - steels and metals

- >

- GIZELIS ROBOTICS

- >

- BENDING APPLICATIONS

BENDING APPLICATIONS

Description

Press-braking is also a popular application for robotic arms. By automating rolling procedures, we attain consistency of end products and provide safety to our work force since many accidents at work have occurred during this application. An important role is played by the gripper, which is mounted on the robot's extremity (flange) and takes on holding the sheets throughout forming. Holding is implemented with under-pressure (vacuum) by means of cup or magnets when sheets have large holes on them. Grippers require special design in order to handle application-specific sheets and not cause problems to the press-brake or the robot during operation.

Similar products

METAL IN LTD

Bulgaria

Metal In Ltd have two punching machines – TRUMPH and Raskin and two CNC bending machines TRUMPH. This allow us to produce punching details with maximum sizes 1250x2500 mm and maximum thickness 4 mm. Machines are with maximum length 3000 mm and power 120 tones. We also have eccentric presss machines with maximum power of kick 160 tones and hydraulic presses with maximum power 100 tones. We have our own production of punching and bending instruments. The company have three roller bending machines for sheet iron, profiles and tubes. Except upper mentioned operations we also make MIG-MAG and WIG welding, cleaning and powder coating.

Request for a quote

ATOM KARINCA LASER

Turkey

ATOM KARINCA can do even the most complex sheet bending operations with the high-tech CNC bending machines and experienced team. We can perform bends with a precision of 0.20 degrees on 3 meters long pieces. Thanks to the station bending capability of our AMADA bending machines, we can produce high-quality parts with repeatable precision.

Request for a quote

TABELARAIZ

Portugal

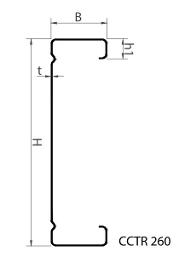

Profiles produced "C' Section characterized as CCTR 260. Discover our catalog here

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free