BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Manufacturer/ Producer

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The DIGIFORCE® 9307 monitors processes in which precisely defined functional relationships between two or more measured quantities need to be demonstrated. These measured quantities are recorded synchronously during the manufacturing process or subsequent functional testing to produce a measurement curve, which is then assessed using graphical and mathematical evaluation techniques. After internal evaluation, the measurement curve and computed evaluation results are visualized on the color display and are also output at the external control interfaces. The processes in the controller are optimized by a powerful real-time operating system to achieve an extremely fast evaluation cycle: it typically takes just 15 ms to deliver the global OK or NOK evaluation result, which can then be analyzed by the higher-level controller.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Pressure on price and quality continue to rise. The need to monitor even the simplest manufacturing and assembly process is increasingly common. With 100% monitoring of force/ time curves or force displacement/time curves, the Force- Master satisfies all requirements for ensuring the reliability of even simple press-fit processes. Thanks to its ultra-simple, single-button operation and intelligent auto-configuration, even semi-skilled staff can set up the equipment safely and quickly. "Card & Go" is the smart system that uses master, tool and PLC smart cards to make equipment settings, inhibit unauthorized changes and to trigger actions in sequence with the production process. The ForceMaster 9110 has been developed specifically for monitoring manual lever presses. Simple manual workstations can be monitored extremely efficiently using the ForceMaster. Easy control functions that used to require an additional PLC can now be performed reliably with the ForceMaster.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental magnetic measuring heads offer maximum precision over the full range of measurements. As a result of the magnetic operating principle and the robust mechanical construction, they are insensitive to soiling and are therefore ideally suited to use in production facilities. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development etc.). Typical applications include: —Monitoring both slow and fast movements between machine parts —Measurements of position and positional changes in components and structural foundations, of servo regulators, valve and robot controllers —Measurement of growth, and so on The incremental displacement sensors are based on a magnetic principle: consisting of a magnetic scale and a multi-slot reading head that responds to changes in magnetic flux, they detect linear movements with high precision and resolution.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental magnetic measuring heads offer maximum precision over the full range of measurements. As a result of the magnetic operating principle and the robust mechanical construction, they are insensitive to soiling and are therefore ideally suited to use in production facilities. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development etc.). Typical applications include: —Monitoring both slow and fast movements between machine parts —Measurements of position and positional changes in components and structural foundations, of servo regulators, valve and robot controllers —Measurement of growth, and so on The incremental displacement sensors are based on a magnetic principle: consisting of a magnetic scale and a multi-slot reading head that responds to changes in magnetic flux, they detect linear movements with high precision and resolution.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental magnetic measuring heads offer maximum precision over the full range of measurements. As a result of the magnetic operating principle and the robust mechanical construction, they are insensitive to soiling and are therefore ideally suited to use in production facilities. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development etc.). Typical applications include: —Monitoring both slow and fast movements between machine parts —Measurements of position and positional changes in components and structural foundations, of servo regulators, valve and robot controllers —Measurement of growth, and so on The incremental displacement sensors are based on a magnetic principle: consisting of a magnetic scale and a multi-slot reading head that responds to changes in magnetic flux, they detect linear movements with high precision and resolution.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The force measuring chain has been developed for applications where the requirements for precision are not the primary focus, but rather where an economical purchase price and simple functionality are the key criteria. The sensor‘s strain gauge technology allows both static and dynamically changing forces to be measured. The large display means that the force acting on the sensor can be read easily. The four integrated threaded holes allow the sensor to be integrated quickly and easily into existing production and assembly equipment. Typical applications include: —Testing the strength of welded joints —Sports medicine —Monitoring the clamping force of hose connections The body of the sensor is a flat, cylindrical disk, into which a domed force application knob is integrated. It is important that the force is applied axially to the center of the sensor.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

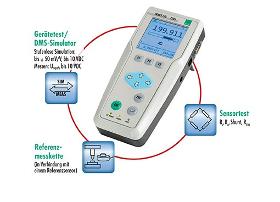

The multipurpose digital indicator TRANS CAL 7281 can be used wherever there is a need to perform high-precision, in-situ calibrations of sensing components used in equipment such as presses, torque tools or pressure-regulating systems. An optional factory calibration certificate or German-accredited DKD/DAkkS calibration certificate can be provided when the measurement device needs to be used as a reference. This provides a quick and cost-effective way of assessing a system with traceable documentation of measurement results. If a reference measurement cannot be made because the sensor location is difficult to access, it is still possible to test the zero point, the input, output and isolation resistance as well as the calibrating offset of the fitted sensor. It is also possible to check the indicating device by measuring the excitation voltage and simulating the characteristic values (mV/V or V) of the sensor used.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

With its flat construction this force sensor is specially designed to be fitted to a pedal. By this, the operator's forces for each respective action, for example brake tests, can be measured directly and the reaction of the vehicle or machine can be designated. This applies to real test drives, as well as in driving simulators. Due to the special construction of the membrane, it is irrelevant whether an upright or hanging pedal is concerned. The sensor is designed in a way that unavoidable lateral forces have as little impact on the measurement result as possible. Using a central internal thread on the control surface, various machine-related adaptor parts can be easily mounted. Because the pedal is convex-shaped on its surface, the pedal force sensor has a very rigid base plate and therefore can easily be applied to various geometrics. The mounting can even take place on a pedal with an elastomer covering.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Fast and accurate measurements of the smallest resistance values are possible with the milliohmmeter RESISTOMAT® model 2316. Due to the rugged aluminium injection moulding desktop housing with membrane keypad it is suitable for use in laboratory and industrial environment likewise. Wires and coils can be measured with temperature compensation. The temperature of the sample is measured with a Pt100 or pyrometer and the resistance is then corrected to the equivalent at e.g. 20 °C (adjustable) in the instrument. The application range is very wide such as the measurement of: — transformer motor coil windings — coils of all kind — cables and wires on the drum or as meter samples — switch and relay contacts — heating elements — fuses — connections and transitions at power rails and many more Specific characteristics: — Autorange — Temperature compensation for all materials — Thermal e.m.f. compensation — Input voltage protection up to effectively 400 V rms

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The RESISTOMAT® model 2329 is particularly suitable for fast measurements of low resistances in automated processes. Up to 50 measurements per second can easily be performed. The device complies with the latest CE guidelines and is designed for laboratory use as well as heavy-duty industrial applications. A 2-fold and 4-fold comparator with switching outputs has been included for classifi cation and selection; this feature is particularly useful for serial tests. One special application involves the measurement of contact resistances (dry-circuit measurement); the load voltage in this case is limited to 20 mV in order to prevent fritting (DIN IEC 512). The RS232 (standard) and IEEE488, USB and Ethernet (option) computer interfaces allow the set-up of fully automatic testing stations. The PLC interface allows easy integration into your production process control.

Request for a quoteManufacturer/ Producer

Talstraße 1-5

76593 Gernsbach - Germany