CDA - Manufacturer of filling & labelling machines

France

Manufacturer/ Producer

CDA

France

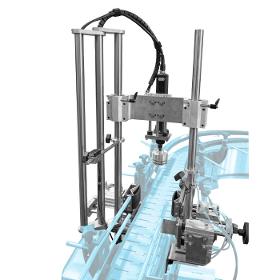

The VS400, an automatic capping module engineered by CDA, seamlessly integrates into various CDA machines, including filling machines like K-Net Auto and K-Line S, as well as monoblocks such as E-Fill. With its diverse array of capping heads, the VS400 accommodates various types of cylindrical caps, such as vertical striated caps, dropper caps, pre-threaded screw caps, screw caps, and hinged lids. This adaptability positions it as an excellent choice for industries ranging from food and cosmetics to chemicals, e-liquids, and cleaning products. A standout feature of the VS400 is its user-friendly design, incorporating a crank height adjustment mechanism, ensuring effortless operation and setup. Furnished with advanced sensors, this capping machine accurately detects the presence of products and caps, guaranteeing a smooth and safe packaging process while maintaining an optimal production rate of up to 25 products per minute.

Request for a quote

CDA

France

The VS500 electric screw capper stands out as a highly efficient automatic capping module featuring an integrated screwer, tailored for various cap types, including spray or pump caps. Its adaptability allows it to handle diverse formats effortlessly, and the crank height adjustment feature ensures optimal performance. Designed to seamlessly integrate into complete filling lines, this automatic screw capper enhances efficiency and productivity. Nevertheless, it can also function as a standalone machine, offering flexibility in its application beyond a comprehensive packaging system. With a 1000mm conveyor, the VS500 achieves speeds of up to 25 products per minute, contingent on specific format requirements, making it well-suited for a broad spectrum of production demands.

Request for a quote

CDA

France

The VSA stands as an independent capping machine featuring an intuitive touchscreen. While this capper can function autonomously, it also offers seamless integration into various CDA machines, including fillers (K-Net Auto, K-Line S), or comprehensive packaging lines. Multiple closing modules can be incorporated into this machine, including: The VS 400 (with tribological or lug screwing head), The VS 500 (featuring natural rubber screwing strips), The pusher (equipped with a stainless steel buffer), The crimper (designed for suitable crimping). The VSA allows for various closing configurations by combining up to two types of cappers, such as a VS400 with a pusher or a VS400 with a VS500. The choice depends on your project specifications and the cap requirements of your products. Manual placement of caps on the container before sealing is conducted by the operator.

Request for a quote

CDA

France

The VST is an automatic module designed for the dispensing and pushing of headed caps. Crafted entirely from stainless steel, this linear machine is developed and produced by CDA. It efficiently dispenses T-shaped caps onto bottles and subsequently pushes them in. With a potential output of up to 1,800 corks per hour (dependent on cork type, etc.), the VST streamlines the capping process. Initially, the corks are placed in the cap lift hopper in a 'loose' manner. The lift then transfers the corks to an orientation bowl, ensuring they are correctly aligned. Subsequently, an automatic distribution mechanism on a ramp feeds the corks (oriented in the right direction) onto the bottle neck. Notably, the lift is a standard feature, enhancing autonomy and simplifying the operator's tasks. Specifically designed for T corks, commonly used in the food processing and distillery industries, the VST stands out for its adaptability and user-friendly operation and adjustment features, such as the

Request for a quote

CDA

France

The VS 1000 automatic capping module, a standalone capping machine crafted by CDA, is versatile and can be adapted to various cap types such as pump caps and spray caps. Designed to accommodate a diverse range of containers, spanning from 20 cl to 5 liters (encompassing vials, jars, bottles, etc.), the VS 1000 automatic capping machine is suitable for a wide spectrum of industries including food, cosmetics, chemicals, paint, cleaning products, and more. This automatic capping machine is equipped with a screwing system powered by two electric screwing machines, incorporating a detection cell to ensure cap presence and facilitating straightforward torque adjustment. Additionally, an optional pushing module can be seamlessly integrated directly onto the conveyor.

Request for a quote

CDA

France

The VS 2000, an automatic screwing machine crafted by CDA, excels at automatically orienting and feeding caps onto containers before securely screwing them. Enclosed within a robust stainless steel frame with Securit glass, this screwing machine ensures durability and safety. Additionally, the VS 2000 can be configured with three sizes of stainless steel conveyors (82.5, 114, and 190mm chain) to suit various applications. This versatile machine accommodates a range of cap sizes, from Ø20 to 75mm. Depending on the cap type, such as grooved caps, smooth hinged caps, caps with integrated lids, childproof caps, etc., the VS 2000 can be equipped with the appropriate system. Ease of use is a highlight of this machine. A vibrating bowl efficiently feeds caps onto a multi-format conveyor belt, featuring a sensor to detect cap presence.

Request for a quote

CDA

France

The DistriCap, an automatic module for dispensing twist-off caps (other formats subject to testing before project validation), is a creation of CDA. Engineered for automatic dispensing and placement of lids onto containers, the DistriCap seamlessly performs these operations "on the fly." This module seamlessly integrates with various machines, either after a CDA filler (such as K-Net Auto or K-Line S) or before an independent screwing machine (like VSA or VS1000). As a result, the DistriCap facilitates the dispensing of a cap or lid before being screwed and/or capped by a screwing module. Depending on the cap type, the machine can have two configurations: Lift/sorter/cap dispenser, typically used for twist-off formats. The lift, a vertical conveyor, sorts capsules by gravity onto a drop-off ramp. Vibrating bowl, commonly employed for plastic lids. The bowl directs caps directly to the appropriate side of the ramp.

Request for a quote

CDA

France

The DS2000 stands as a standalone cap unscrewing machine, featuring an intuitive touchscreen interface. While it excels in autonomous operation, it seamlessly integrates into various CDA machines, including fillers like K-Net Auto and K-Line S, or complete packaging lines. Engineered to unscrew a diverse array of caps, the DS2000 finds applicability across multiple industries, including food, cosmetics, chemicals, and e-liquids. Its distinctive capabilities include the adjustment of motor speed, position, torque, acceleration, and deceleration, coupled with clamp movement. With a production rate of up to 1,500 products per hour, it offers versatility to accommodate different product shapes. To further augment its functionality, optional solutions for vial feeding and discharge are available, such as an independent rotative table.

Request for a quote

CDA

France

The CDA Ninette 1 stands out as a semi-automatic labeling machine designed for the precise and efficient application of adhesive labels on cylindrical products like wine and beer bottles, cans, tins, bottles, vials, jars, etc. With a labeling rate reaching up to 8 products per minute or 600 bottles per hour, it proves highly effective. This versatile semi-automatic labeling machine finds application across diverse sectors, including viticulture, brewing, the food industry, and cosmetics. With its labeling station, it accommodates various formats and materials such as glass, PET, and PVC. The Ninette 1 is celebrated for its user-friendly operation, excellent price-to-quality ratio, and, most notably, its robustness.

Request for a quote

CDA

France

The CDA Ninette 2 stands out as an efficient semi-automatic labeling machine designed to apply two adhesive labels simultaneously on cylindrical products. Boasting an impressive speed of up to 600 bottles per hour, the Ninette 2 is a versatile solution suitable for a diverse range of industries. Whether you operate in the wine and spirits sector, brewing industry, food and beverage production, or cosmetics, this labeller excels at handling various product formats, including wine bottles, beer bottles, cans, jars, pots, and more. A notable advantage of the Ninette 2 lies in its exceptional versatility. It accommodates products of different compositions, such as glass, PET, and PVC, without necessitating material changes. This flexibility ensures a smooth integration into your existing production line, streamlining your operations. The Ninette 2 addresses the needs of small businesses and SMEs seeking a labelling solution for their small-scale productions.

Request for a quoteManufacturer/ Producer

6 rue de l'Artisanat

Zi de plaisance

11100 Narbonne - France