- europages

- >

- Crimping machines

- >

- CL MACHINERY GMBH

CL MACHINERY GMBH

Germany

Manufacturer/ Producer

CL MACHINERY GMBH

Germany

Closure Systems International’s PP136 Capper is a single head capping machine that operates in a manual configuration for sealing bottles and containers of various shapes and sizes. The PP136 bottle capper is popular for custom package applications and small volume production, such as in performance laboratory and research environments. Simple Operation Can quickly and easily change package and closure sizes on the single head by adjusting the bottle stop and operation height Bottles and closures are positioned manually, allowing for automatic capping by lowering the headset onto the bottle finish High Performance Standard Features Neck support assembly Bottle control support increases package size range for small bottles Robust construction: machine body made of cast iron Versatile & Customizable Can be configured for a wide variety of closure types, including plastic closures and aluminum roll-on caps; includes parts for quick changeover Can be designed for many package...

CL MACHINERY GMBH

Germany

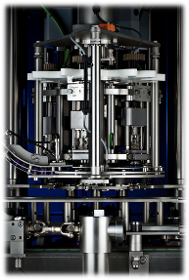

Closure Systems International's Intelli-Torq Servo cappers set the standard for plastic closure application quality control, guaranteeing safer and more efficient production. These cappers incorporate full stainless steel construction and have an open design that facilitates cleaning and rinsing. CSI's Intelli-Torq Servo Cappers are also fully metric, perfect for global use. Intelligent Capping for Maximum Efficiency Pre-set application recipes In-line quality control for product assurance and proof that only perfect products leave production lines Computer-controlled capping with monitoring of application torques and angles Application torques documented on a continual basis Detection and removal of defective product, minimizing risk of product liability claims Data storage Highest quality assurance, control and cost savings Reliable & Robust Robust, durable construction for long-lasting performance Full stainless steel construction to prevent corrosion Stationary servo motors..

CL MACHINERY GMBH

Germany

Closure Systems International’s Series 200 bottle cappers are the ultimate for aluminum roll-on applications. CSI's custom-engineered and precision built Series 200 cappers have been the preferred choice of the beverage and beer industry for decades. Industry’s Best TSROPP Performance Two cams provide independent control of top seal and thread forming, allowing precise control for specialty aluminum / roll-on packaging Perfect for roll-on closures requiring top/side sealing Robust, durable construction for long-lasting performance Corrosion-resistant materials in product zone; full stainless steel option Direct integration with any filler: various custom drive systems and pitch diameters to match filler, sorter and other bottling line equipment choices Open design for ease of cleaning Easy removal spindle assembles for quick maintenance Industry leader in Alumitec Application High-Speed, Consistent Application Industry-leading throughput at 50 BPM / 3,000 BPH per head Proven...

CL MACHINERY GMBH

Germany

Closure Systems International’s Series 200E capping machines are recognized as the "workhorse" of the capping industry for their reliability and low maintenance. The proven performance and flexibility allows bottlers to apply plastic and aluminum closures for a wide variety of applications at the highest possible speeds. Best Reliability & Robustness Robust, durable construction for long-lasting performance Proven headset designs for consistent application and torque control Corrosion-resistant materials in product zone; full stainless steel option Direct integration with any filler: various custom drive systems and pitch diameters to match filler, sorter and other bottling line equipment choices Integrated PLC with touch screen to monitor application conditions and provide effortless user interface Auxiliary closure buffer for unexpected interruptions Quick, Easy Maintenance & Changeovers Simplified low maintenance requirements to reduce downtime Totally enclosed washable...

CL MACHINERY GMBH, formerly ALCOA Maschinenbau, located in Viernheim, is a global manufacturer and supplier of closure technology. The CSI product range includes capping equipment, sorting technology for caps and decappers for a wide range of packaging concepts. As a specialist in closure application, CSI offers solutions for processing aluminium roll-on caps (e.g. Talog, 5SE, Stelvin, LongCaps, pourers), plastic screw caps, MaxiCrown caps/ring pulls, synthetic corks, twist-off caps, press-on caps, StelvinLux, etc. for a wide range of market segments. These include the drinks industry, breweries, wine and sparkling wine bottling plants, mineral springs, the food processing industry, the chemical and pharmaceutical industries as well as the aerosol market segment (spray cans). Here, CSI provides closures for both glass and plastic bottles along with aluminium bottles and spray cans (aluminium/steel).

Website

Documents

Manufacturer/ Producer

Mainzer Strasse 187

67547 Worms - Germany

Company info

Key figures

-

- Company headcount

- 11 – 50

Organisation

-

- Year established

- 1968

-

- Site status

- Registered office – Parent company

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Activities of CL MACHINERY GMBH

- Crimping machines

- Seal tensioners

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

UNIFLEX-HYDRAULIK GMBH

Germany

Due to their compact, all-round accessible construction, high level of user friendliness, and long service life, the HM4xx set the standard for quality and cost effectiveness. The crimpers‘ particularly large opening stroke and the use of long master dies allow you to crimp all types of fittings and up to 8" industrial hoses.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

As reliable classic machines, the HM3xx series unites all the outstanding properties of a production crimper. Combining a convincingly solid construction with a high level of user friendliness, and long service life, the HM3xx set a new standard for quality and cost effectiveness. They are compact, powerful and make ergonomic working possible.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The hose press S2 is available in various variants, perfectly adapted to your needs: S2 - Standard S2 M H Ecoline - Manual, developed pump S2 M Ecoline - Manual S2 P - Pneumatic S2 A - Automatic S2 DC -different voltages possible The new S2 M Ecoline H helps reduce machine downtimes The S2 M Ecoline crimper from UNIFLEX weighs only 30 kg and is the ideal device for the on-site repair of hydraulic hoses in construction and agricultural machinery. Hose connections up to 1" (for 2-part fittings) or 1 ¼" (for single-part fittings) can be established easily and safely – without the need for lubrication, and protected by a sturdy frame. In high-gear mode, the new two-stage pump of the S2 M Ecoline H line works three times faster than previous models. Thanks to the retractable lever, the compact device takes up only minimum space when stowed away.

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A system for automatically closing plastic containers ■ Automatic single head capper with an automatic lowering capping head which closes canisters with a plastic cap ■ Automatic cap sorter - sorts the caps and leads them to the capping head ■ Modular construction - System configuration on a modular principle, made of stainless steel grade 304

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free