- europages

- >

- Vibrators- industrial - installations

- >

- COPENHAGEN VIBRATOR PRODUCTS

COPENHAGEN VIBRATOR PRODUCTS

Denmark

Wholesaler

The company COPENHAGEN VIBRATOR PRODUCTS, is a Wholesaler, which operates in the Vibrators, industrial - installations industry. It also operates in the mechanical vibrators for industrial use, and electric vibrators industries. It is based in Bjæverskov, Denmark.

Other companies in the same industry:

Website

Company info

Key figures

-

- Company headcount

- 1 – 10

Organisation

-

- pages.epage-home.site-status

- Registered office

-

- Main activity

- Wholesaler

Business info

Trading areas

- National

- International

Delivery areas

Activities of COPENHAGEN VIBRATOR PRODUCTS

- Vibrators, industrial - installations

- mechanical vibrators for industrial use

- electric vibrators

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

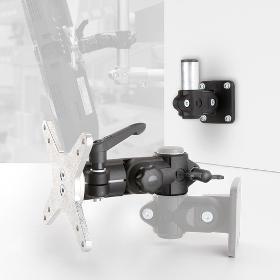

RK ROSE+KRIEGER GMBH

Germany

Monitor swivel arms for ergonomic workstation design The monitor mountings from RK Rose+Krieger allow for an optimal view of the monitor or a control panel. The range of action can be increased even further by using a swivel arm. This may be useful for carrying out set-up work on machinery for example, or if the monitor is having a disruptive impact on the working environment. There is also the option of expanding the support arm with two support tubes (twin version) to include a sturdy keyboard tray. The modular design of the RK swivel arm/support arm system allows for varied combination options and helps to adapt workstations to the most ergonomic arrangement.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

RK monitor mounting – high-strength, flexible and individually adaptable VESA or universal mount for connecting monitors, displays or control panels. Monitors, touch screens, displays and control panels are used every day, and not just in the office. Industrial machines and systems are programmed or performance data displayed on modern touch screens or control panels. In utility vehicles, camera monitoring systems facilitate resetting and navigation devices make positioning possible. On conveyors, monitors make it possible to monitor and visualise all sorts of processes. Today, control panels or flat screens are often an essential component of modern assembly workstations, too. Standard systems are generally designed for office applications. Industrial environments push these monitor mountings to their limits. For example, they normally can carry loads of only six to twelve kilograms and are not robust enough for use on machines, systems or assembly workstations.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

Based on a individual needs assessment we tailor-make briquetting solutions including peripheral devices.

Request for a quote

MICROMEGA DYNAMICS S.A.

Belgium

The Recovib.Tiny is a 3-axis shock & vibration data logger. It is extremely practical for a vibration diagnosis, offering up to 6 hours of measurement. Its wireless technology and intuitive operation provides substantial time savings in the performance of your measurements. It is the only type of vibration and shock recorder that allows several sensors to be used simultaneously in a synchronized manner enabling the performance of modal analyses and operational deflection shape analyses on large structures such as bridges or Walkways. It is able to record 1024 acceleration values (shocks and vibrations) per channel per second. The RECOVIB Tiny is the smallest, lightest and the most robust recorder on the market that is able to perform recordings in extreme conditions ranging from -10°C to +50°C. It is also dust and watertight to IP65.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free