- europages

- >

- Clutches

- >

- AMSBECK MASCHINENTECHNIK GMBH

- >

- Centrifugal clutches with belt tensioner

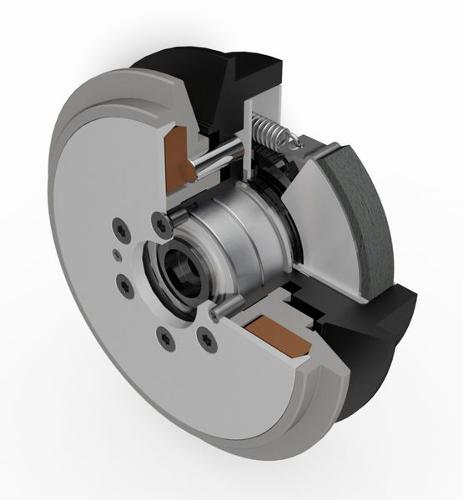

Centrifugal clutches with belt tensioner

Centrifugal clutches with belt tensioner

Description

For centrifugal clutches with belt outputs, the belts must be pre-tensioned in order to maintain the pressing force required to transfer force. Usually, tensioning rollers are used in the belt drive for this purpose. However, tensioning rollers are hard to use with short axle distances. The tried-and-tested centrifugal clutch with integrated, automatically acting belt tensioner compensates the length changes of the V-belts by adjusting the diameter of the pulley. Typically, these centrifugal clutches are used in high-quality reversible shaker plates.

- Clutches

- centrifugal clutch

- drive technology

- starting clutch

Product characteristics

- Size / nominal diameter

- 60 - 250

- Standard borehole d (mm)

- 10 - 75

- d max. (mm)

- 20 - 80

- Outer diameter D (mm)

- 60 - 250

- Width B (mm)

- 20 - 30

- Md1 [Nm] at nE 750 and nB 1500 [1 / min]

- 1,7 - 720,5

- Recommended power P1 [kW]

- 0,1 - 56,6

- Md1 [Nm] at nE 750 and nB 2500 [1 / min]

- 4,8 - 2001,3

- Recommended power P2 [kW]

- 0,6 - 262,0

- Md1 [Nm] at nE 750 and nB 3500 [1 / min]

- 6,9 - 2881,9

- Recommended power P3 [kW]

- 1,1 - 452,7

Documents

Similar products

IGUS® GMBH

Germany

The drive technology online configurator gives you the right drive technology system after you enter your requirements. You also have the option of requesting or ordering motors and other accessories, such as the motor control system. - Fast and easy configuration - Optional accessories - Detailed parts list - Fast delivery

Request for a quote

BVS ELECTRONICS GMBH

Germany

Lenze drive technology Regardless of whether you require motors, gear units or specific drive elements, we have an extensive selection of products manufactured by Lenze to meet your exact requirements. This includes frequency converters and servo motors as well as various accessories, such as signal and power cables, function modules, handheld terminals and mounting kits. We not only complete repairs for products manufactured by Lenze but also sell and service these modules.

Request for a quote

SIKO GMBH

Germany

Magnetic motor feedback systems are proving themselves in numerous applications in linear drive technology, handling systems, circuit board assembly, robotics and in a wide range of automation solutions in the context of Industry 4.0. In all of these areas, the speed and/or position of a drive must be communicated to a main controller in real time. The ultra compact LEC100 and LEC200 sensor duo has been developed by SIKO for these requirements. Repeat accuracy max. ±1 μm. max. resolution 0.2 µm (LD output circuit). Reading distance ≤0.2 mm. Works with MB100/1 magnetic tape. Signal period 1000 μm. Output circuit sin/cos or LD. Function and status display LEDs.

Request for a quote

FÖHRENBACH GMBH

Germany

2-phase stepper motors Our 2-phase stepper motors are reliable and low-cost drives with a long service life. They are available in different sizes and types of power output, are continuously developed and are thus suitable for a variety of applications. AC servo motors The AC servo motors meet the highest demands regarding dynamics and accuracy and are used if dynamic, exact positioning or smooth running characteristics are required. The different types of power output and sizes cover the most diverse requirements. The benefits at a glance Highly dynamic High efficiency Long service life

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free