- europages

- >

- Clamp collars- plastic

- >

- NORELEM FRANCE

- >

- Clamping pin steel

Clamping pin steel

Clamping elements for grid systems

Description

The screw is tightened or the clamping lever is turned to expand the two wedges in the hole. The infinitely adjustable shaft collar enables one or more stop elements with various thicknesses to be securely fixated. Application: These clamping pins are perfect for fixing standard stop elements with various thicknesses to hole grid boards / welding tables with hole Ø 16 mm or 28 mm. Advantages: Infinitely adjustable clamping range of 0-36 mm and 0-75 mm. Not affected by the diameter or surface quality of the bore (up to H12). Clamping range can be easily preset using the scale. Gentle clamping in the bore. Pull-down effect even with thin table material (≥8 mm or ≥4 mm). Compatible with conventional stop elements.

- Clamp collars, plastic

- Clamping pin

- Steel clamping

Similar products from NORELEM FRANCE

NORELEM FRANCE

France

Tightening the ball-end thrust screw moves the jaw plates forwards. The workpiece is pushed against the fixed stop and simultaneously forced down onto the seating face. The seating face for the workpiece can be mounted directly on the machine table.

Request for a quote

NORELEM FRANCE

France

Interchangeable subplates are particularly suitable for quickly exchanging fixtures on zero point clamping plates. Ground on both sides, standard clamping pin gauge of 200 mm. Complete with clamping pins and handles. On request: Further gauges and special sizes.

Request for a quote

NORELEM FRANCE

France

Body and clamping pin oxidised. Contact faces hardened and ground. Note: The UNI lock 5-axis add-on modules are used for raising basic modules and mounting base. Depending on the clamping situation, optimum assembly height can be achieved using a combination of the basic module and add-on module.

Request for a quote

NORELEM FRANCE

France

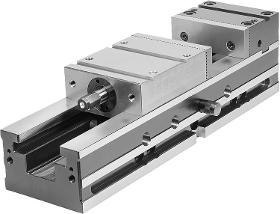

NC vices can be used for a wide range of clamping tasks: Repeat accuracy ≤0.01 mm Fixed jaw locked in all directions (X,Y,Z) Vertical use directly on the machine table Wide clamping range by using attachment step jaws Can be laid on the side, with fastening holes for slot spacing of 63 mm and 100 mm Quick pre-adjustment of the clamping range using locking pins Basic equipment includes two reversible screw-on jaws and one crank handle

Request for a quote