- europages

- >

- Wood veneer - machinery and equipment

- >

- SIEMPELKAMP MASCHINENFABRIK GMBH

- >

- Contitherm – Insulation Board Press

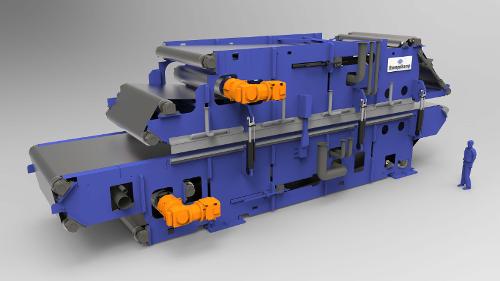

Contitherm – Insulation Board Press

Description

The ContiTherm is the optimally suited for the production of wood-based insulation material, the wood bres being preferably resinated with PMDI or thermoplastic melts. A steam/air mix is conveyed through the bre mat. During this process, the steam condenses at the bres or particles, heating them up. At the same time the gap between the upper and the lower hot platens is precisely maintained. This is essential for the production low-density boards of up to 250 kg/m³ approx. which exhibit outstanding thermal insulating propertie The dew point of the steam/air mix - thus the mat temperature - can be precisely set by varying the steam content. T sections (seen in working direction). Depending on the application these sections are designed for a unidirectional o with hot platens heated by thermal oil. The width of the steam boxes in an MDF-plant can be extended by additional segments to optimise steam-air conve

- Wood veneer - machinery and equipment

- Sienpelkamp Insulation Board Press

- Contitherm Board Press

- Sienpelkamp

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free