- europages

- >

- Steels and metals - welding and brazing

- >

- SCHNELLDORFER MASCHINENBAU GMBH

- >

- Corner Seam Welding Machine

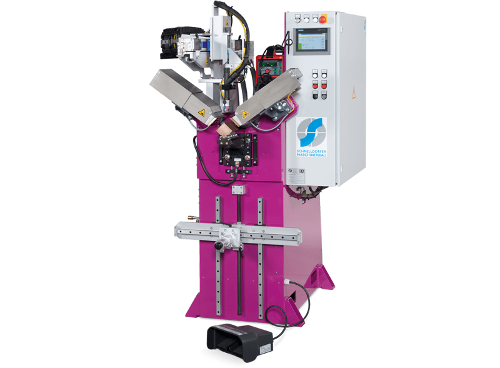

Corner Seam Welding Machine

CORNERWELD

Description

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

- Steels and metals - welding and brazing

- Welding Divices

- Corner Welding

- Tig Welding Robots

Product characteristics

- Pneumatic safety clamping system

- No need for post weld grinding and polishing

- welded sheet metal plates with a 90° joint

- max. welding length: 300 mm or 500 mm

Similar products from SCHNELLDORFER MASCHINENBAU GMBH

SCHNELLDORFER MASCHINENBAU GMBH

Germany

ROTAWELD is our platform to cover a wide range of applications requiring circumferential seam welding. The precision servomotor rotation axis combined with our advanced control system form the basis for the production of accurate and repeatable circumferential seam welds. Machine sizes, part holders, welding equipment, torch holders and any additional positional axes are designed specific to the customer and their products.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

High quality, productive longitudinal seam welding calls for the utilisation of advanced, superior technology. This enables us to us to protect and expand our market position despite increasingly fierce competition. Our ELENA® longitudinal seam welders provide unsurpassed technology for welding of longitudinal metallic seams.

Request for a quote