EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Manufacturer/ Producer

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

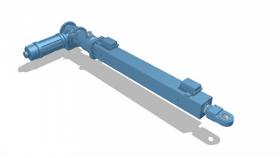

In many areas of mechanical engineering, electromechanical drives are replacing hydraulic units in order to avoid the risk of oil leaking into water or the danger to people from burning liquids. Our electric lifting cylinders have been specially developed for use in hydraulic steel construction. They are suitable as drives for contactors and bridge actuation, as well as for lock gates and barrages. With our modular system, various designs such as trapezoidal, ball or planetary roller screw drive can be realized. Limit switches for permanent travel or load measurement can be integrated. The drive systems are equipped with environmentally friendly, biodegradable fat filled to meet the strict environmental requirements. They are characterized by a special design adapted to the intended use, a high level of serviceability and versatility. Our electric lifting cylinders form a reliable and sustainable alternative to hydraulic lifting cylinders in various fields of application.

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

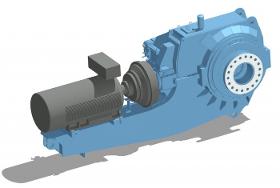

Sophisticated drive concepts for ball mills and rotary kilns require powerful solutions. Eickhoff offers different gear solutions for the various drive concepts established in the field, such as side drive, central drive and direct drive. In addition to the robust Eickhoff helical gearboxes, our ED planetary gearboxes are preferred, especially for a central drive. They offer a compact solution with extremely high power density and are therefore also leading from an economic point of view. Even torques of over 7,000 kNm can be realised. Typical applications are the crushing of raw materials as well as the burning of cement clinker. The gears are characterised by a long service life and high power density.

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

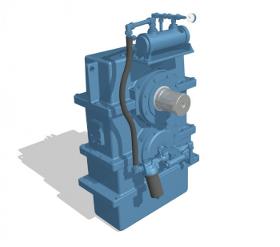

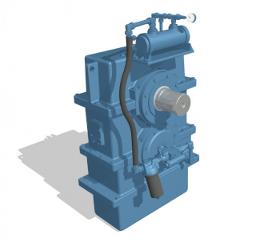

Eickhoff planetary gearboxes are ideal for driving large industrial plants. With our roller press gears of the new ED series we cover a wide torque range from 220kNm up to more than 7,000kNm. The special non-contact sealing system also makes our gearboxes very low maintenance. Convince yourself of the efficiency of our roller press gears, which are used for the crushing and grinding of raw materials. If necessary, we will adapt the gearbox to your requirements and develop the entire drive concept together with you. All our gearboxes can be equipped with an additional sensor system, which enables a permanent monitoring of the operating status. This allows operation-relevant risks to be detected at an early stage in order to counteract a possible unexpected machine failure. Advantages at a glance: — Compact design with highest power density — Reliable and low maintenance — Flexible design variants and accessories — Large capacity range

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Eickhoff offers application-specific solutions for winch systems in the field of lifting and conveyor technology. Even torques of over 2500 kNm are no problem. Our planetary gearboxes are characterised by a compact design and high power density, which is particularly advantageous in space-critical fields of application such as the maritime sector. The direct integration of our gearboxes into the rope drums can be realised individually. Due to the high efficiency of the planetary and spur gear units, they operate with extremely low losses. Based on our modular system, solutions can be derived individually adapted to the respective application. Advantages at a glance: — Compact design — High efficiency — Reliable and low maintenance — Customized solution

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Eickhoff has been a renowned manufacturer of axle drives for rail vehicles such as locomotives and track work vehicles for more than five decades. The wheelset drives can be designed as bevel gears, spur gears or customized solutions, so that they optimally meet the performance requirements. We meet the high-quality standards in the field of transport technology thanks to our many years of experience in service and more than 2000 newly delivered final drives. Our gearboxes are robust, durable and designed for use under extreme conditions.

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Eickhoff gear solutions for bucket wheel excavators / stackers / reclaimers are characterised by a compact design, high adaptability and low weight. The robust gearboxes are perfectly matched to the requirements and ensure maximum availability for the mining and transport of raw materials. Our gear units are used as bucket wheel drive, travel drive or conveyor drive. When replacing existing drives, in many cases the weight can be reduced even further by increasing the performance. Advantages at a glance: — Customized solutions — Compact and weight-optimized construction — High power density — Reliable and low maintenance

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

The unrestricted availability of energy is playing an increasingly important role. Highly efficient gas or diesel generators, so-called gensets, are used as power generators, e.g. as emergency power generators in hospitals or as temporary power suppliers in areas that are difficult to access. Another area of application is large data centres, where the unrestricted and uninterrupted availability of electricity must be guaranteed. Gensets ensure the power supply in any situation, even under extreme conditions. Our genset gearboxes are connected between the motor and the generator, so that a frequency adjustment for the required power grid is achieved. It is possible to adjust the frequency from 50Hz to 60Hz as well as from 60Hz to 50Hz. The speed transmission is highly efficient, as the single-stage spur gears guarantee a high efficiency of >99%. The use of a labyrinth sealing system also means that the drives require very low maintenance.

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

The unrestricted availability of energy is playing an increasingly important role. Highly efficient gas or diesel generators, so-called gensets, are used as power generators, e.g. as emergency power generators in hospitals or as temporary power suppliers in areas that are difficult to access. Another area of application is large data centres, where the unrestricted and uninterrupted availability of electricity must be guaranteed. Gensets ensure the power supply in any situation, even under extreme conditions. Our genset gearboxes are connected between the motor and the generator, so that a frequency adjustment for the required power grid is achieved. It is possible to adjust the frequency from 50Hz to 60Hz as well as from 60Hz to 50Hz. The speed transmission is highly efficient, as the single-stage spur gears guarantee a high efficiency of >99%. The use of a labyrinth sealing system also means that the drives require very low maintenance.

Request for a quoteManufacturer/ Producer

Am Eickhoffpark 1

44789 Bochum - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and ring gears. We supply already well-known manufacturers for gear boxes, drive technology and are looking forward to new customers. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / ring gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English. ZWP is looking forward hearing from you.

Request for a quote

NOVELTY STEEL

Turkey

Apron feeders come in varying widths, ranging from 0.6 to 3.0 meters, and lengths spanning from 2.4 to 30.5 meters. Lengths exceeding 4.6 meters are primarily used for material conveyance rather than being an integral part of the feeder. Apron feeders exhibit capacities ranging from 91 to 2,270 tons per hour. The power requirements for apron feeders are approximately twice as high as those for comparable belt feeders. Apron feeders are typically employed in situations involving truck dumps or other scenarios where very coarse materials are handled, such as in the feeding of primary or secondary crushers. When an apron feeder is intended for use under a truck dump hopper with an elongated hopper opening, it’s essential to design the hopper with a taper that widens in the direction of horizontal flow for belt feeders. Novelty Structures supplies various types of feeders such as; * Apron Feeders * Belt Feeders * Rotary Table Feeders * Screw Feeders

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free