ENKI WATER TREATMENT TECH. LTD

Turkey

Manufacturer/ Producer

ENKI WATER TREATMENT TECH. LTD

Turkey

Media filter is used to reduce the level of suspended solids (turbidity) in feed water. Suspended solids consist of small particles such as silt, clay, grit, organic matter, algae and other microorganisms. Feed water that is high in suspended solids can cause a high pressure drop and reduce the effectiveness of downstream equipment such as reverse osmosis membranes and ion exchange beds.

ENKI WATER TREATMENT TECH. LTD

Turkey

When is used an activated carbon filter? Activated carbon filters are very similar to multi media filters and other pressure filters in construction and operation. The purpose of an activated carbon filter is to remove free chlorine, an oxidizing agent that will damage most resins and/or membranes in a water treatment system. A chemical injection system using sodium bisulfite (a reducing agent) can be used in place of an activated carbon filter to remove chlorine. Granular activated carbon is a particularly good adsorbent medium due to its high surface area to volume ratio. One gram of a typical commercial activated carbon will have a surface area equivalent to 850-1.000 square meters. This high surface area permits the accumulation of a large number of contaminant molecules. Some drinking water may be disinfected with chlorine or chloramines.

ENKI WATER TREATMENT TECH. LTD

Turkey

Reverse osmosis is the finest level of filtration available. The reverse osmosis membrane acts as a barrier to all dissolved salts and inorganic molecules, as well as organic molecules with a molecular weight greater than approximately 100. Water molecules, on the other hand, pass freely through the membrane creating a purified product stream. Rejection of dissolved salts is typically 95% to greater than 99%. Classification of brackish water: • Low salinity brackish waters: up to 5.000 ppm • High salinity brackish waters: between 5.000 - 15.000 ppm • Sea water: up to 45.000 ppm Reverse osmosis is a technology that is used in the production of ultrapure water for use in the semiconductor industry, power industry (boiler feed water), and medical/laboratory applications. Utilizing reverse osmosis prior to ion exchanger dramatically reduces operating costs and regeneration frequency of the Ionen exchanger plant.

ENKI WATER TREATMENT TECH. LTD

Turkey

A "CO2 degasser" (degassifier) is a relatively simple water treatment device. Incoming water is sprayed into a tower filled with packing material. The drops of water that flow down through the tower strike the packing material and form a thin film on the packing material surface, encouraging the release of excess carbon dioxide. A centrifugal fan creates an updraft of air through the tower to carry away the released carbon dioxide gas. The carbon dioxide gas exits through a vent at the top of the unit.

ENKI WATER TREATMENT TECH. LTD

Turkey

In comparison to conventional water treatment processes, the advantage of "ultrafiltration" as a filter technology is its superior ability to remove germs and microorganisms from water. At around 20 nm, the pores of the membrane are small enough to prevent even viruses from passing through them. "Ultrafiltration" systems are designed for fully automatic operation. A control mechanism is used to control the various operating modes of the ultrafiltration process: filtration, cleaning and backwashing. enki’s industrial ultrafiltration units are available from 25 to 500 m3/h and more . Our ultrafiltration systems are available in either Outside-In or Inside-Out configurations. Outside-In configuration UF Systems; DOW H-PVDF Hollow Fiber UF Membranes Inside-Out configuration UF Systems; Inge PESM Hollow Fiber UF Membranes

ENKI WATER TREATMENT TECH. LTD

Turkey

enki’s package water treatment plant (Compact water unit) is used to treat surface water supplies for the removal of suspended solid, color and coliform with classical water treatment process. Our package water treatment plant is pre-assembled in factory and ready to the site. Package water treatment plant is a compact and standardized unit for treated water demands of the small communities and industries. The plant capacity can be increased by adding skid mounted containerized modules. Package water treatment plant is mainly consisting of : coagulation, lamella clarifier, filtration, chemical dosing unit , control panel auxiliary equipment. All equipment will be mounted in the container or in skid. At site will be mounted the piping and electrical cabling between container.

ENKI WATER TREATMENT TECH. LTD

Turkey

Our containerized reverse osmosis plant is installed in 20 /40 ft containers. Containerized Reverse Osmosis Plants produce fresh drinking water from brackish water according to the standards of the World Health Organization (WHO) It is possible to transport from site to site. The capacity of our containerized reverse osmosis unit from 10 to 50 m3/h. enki design containerized reverse osmosis system according to custom requirement and specific application.

ENKI WATER TREATMENT TECH. LTD

Turkey

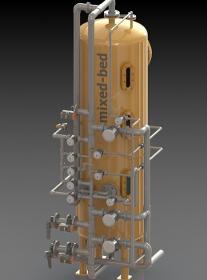

Both cation and anion resin can be feed in to an ion exchanger tank and mixed to create a mixedbed ion exchanger. A mixedbed ion exchanger is more complicated than other types of ion exchangers because it has to separate and regenerate the two resins. The carefull mixing of the cation and anion resin allows a very high degree of deionization. Mixed bed ion exchangers produce the highest quality demineralized water of any of the ion exchanger units. Working mixedbed ion exchangers deionize water with up to 50 ppm TDS (Total Dissolved Solids). Polishing mixedbed ion exchangers are located after cation and anion exchangers or reverse osmosis units Strong acid cation and strong base anion resins are used in mixedbed ion exchangers, as complete demineralization is the objective. A small volume of inert resin can also be used to facilitate separation of the cation and anion resin beads during regeneration

ENKI WATER TREATMENT TECH. LTD

Turkey

Ammonia NH3, Hydrogen Sulfide H2S The collection and processing of sewage and industrial waste water is often a source of unpleasant odors mainly ammonia (NH3) and Hydrogen sulfide (H2S). These odors come from screening unit, sand/grit removal unit, pump station and sludge dewatering unit. enki’s two stage counter-flow vertical Packed Bed Scrubber removes these odors. The first packed tower uses aqueous sulfuric acid (H2SO4) solution to remove ammonia (NH3) according to the below reaction: 2NH3 + H2SO4 ➝ (NH4)2SO4 Ammonium sulfate salt [(NH4)2SO4], is soluble and non-volatile and it is easily removed by the blowdown. In the second stage are used sodium hydroxide (NaOH) and sodium hypochlorite (NaOCl) solution. NaOCl oxidizes the hydrogen sulfide. The complete reaction is given below: H2S + 4 NaOCl + 2NaOH ➝ Na2SO4 + 4NaCl + 2H2O Na2SO4 and NaCl are removed by the blowdown. The efficiency for removal of NH3 and H2S is greater than 99%.

Manufacturer/ Producer

Sefaköy

34295 Istanbul - Turkey

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Water treatment for steam boiler systems — Prevention of corrosion in the boiler — Outstanding deaeration efficiency and reduced consumption of chemicals with WSM-V complete deaeration system — Partial deaeration module WSM-T for small systems — Fast and easy planning, installation and acceptance appropriate to the steam boiler in question — Requirement for positive suction head allows for ground-level installation and easy commissioning

Request for a quote

PJM MECHANICAL CO.,LTD

China

We take great pride in the consistent quality of our gears. Our gear inspection equipment is accurate and dependable, ensuring your gears will meet the most demanding performance requirements. Surrounded by the POWER JACK MTOION Gear network, we are capable of performing a wide range of gear inspection operations as part of our precision gear manufacturing services for both small volume and large volume orders.

Request for a quote

CANALETAS

Spain

Easy installation only requires an electrical connection. With a compact design, to be situated on any kitchen surface, meeting rooms... Approximate capacity of up to 15 20 users. Rectangular design for more durability. Superior quality. Made from A304 stainless steel. Easily regulated water temperature (thermostat). Made to be used with smaller bottles in order to save space and more comfort. Easy to remove drip tray. Optional cup dispenser. Optional refillable bottle.

Request for a quote

CANALETAS

Spain

The household reverse osmosis filtration system gives a high purity of drinking water through a system of high capacity filtration that removes even the smallest microorganism or particles that may be present in the water. The filtration system consists of: Prefilter for sediment. Activated carbon filter. Reverse osmosis membrane. Postfilter activated carbon filter. A patented reverse osmosis unit that is unique on the market, whose design avoids the need for multiple connections and tubes, and possible water leaks. System with easy to replace filters. It incorporates a pump that ensures the required water input pressure necessary for proper operation and a pressured accumulator tank of 12 liters. It is installed under the sink in the kitchen and requires water inlet, drainage and electricity like a washing machine. A faucet for purified water has to be installed which can be the standard equipment or the special three way faucet head model with a more elegant design.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free