Comparison ERO Joint HP & Pin joint

ERO Joint® belts ・ 20 Feb 2020Discover the comparison ERO Joint® HP & Pin Joint in video : https://www.ero-joint.com/en/comparison-ero-jointr-hp-pin-joint

France

Manufacturer/ Producer

ERO JOINT .TANALS

France

Exclusive Gates and Tanals The only power transmission belt with mechanical assembly The mechanical fastening system ERO Joint® - developed by Tanals - provide various possibilities to assemble belts on-site without having to disassemble pulleys or axes and to release the transmission. ERO Joint® and ERO joint® Ultimate are developed for and with Gates by Tanals. They offer unique solutions system for easy and fast repair of power transmission. The cutting shapes of the junction fingers have been engineered for maximum tensile strength and fatigue resistance of the Poly Chain® GT Carbon™ material. The power of Gates combined with the know-how of Tanals. Poly Chain® GT Carbon™ outstanding mechanical performance combined to ERO Joint® provide the only existing transmission belt with mechanical assembly. The only existing transmission belt with mechanical assembly, a unique solution on the market. Suitable for all HTD installations.

Request for a quote

ERO JOINT .TANALS

France

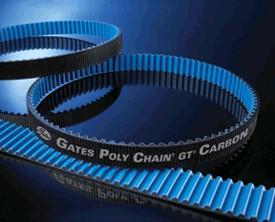

In addition to providing a high quality and technology in drive solutions, Gates also provides you expertise on synchronous drive systems. The Poly Chain® GT Carbon™ is the new polyurethane synchronous belt by Gates, manufactured with patented carbon tensile cord and providing a high torque and low speed drives. Engineers from the materials development department of Gates are the pioneer in high fatigue-resisting carbon fibre tensile cord incorporated into a new polyurethane compound belt. Then the Poly Chain® GT Carbon™ is the most potent synchronous belt in the transmission world, and provide a maintenance-free, energy saving and eco-friendly operation. It is a brilliant substitute to roller chain and gear drives.

Request for a quote

ERO JOINT .TANALS

France

Exclusive Gates and Tanals The only power transmission belt with mechanical assembly The mechanical fastening system ERO Joint® - developed by Tanals - provide various possibilities to assemble belts on-site without having to disassemble pulleys or axes and to release the transmission. ERO Joint® and ERO joint® Ultimate are developed for and with Gates by Tanals. They offer unique solutions system for easy and fast repair of power transmission. The cutting shapes of the junction fingers have been engineered for maximum tensile strength and fatigue resistance of the Poly Chain® GT Carbon™ material. The power of Gates combined with the creativity of Tanals. Poly Chain® GT Carbon™ outstanding mechanical performance combined to patented innovative solution ERO Joint® Ultimate offer the only transmission belt with mechanical assembly whose performances equal those of all other endless belts on the market. A sustainable solution able to replace any rubber belt.

Request for a quote

ERO JOINT .TANALS

France

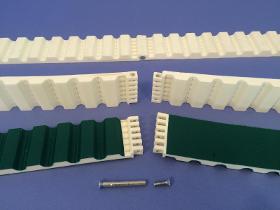

ADVANTAGES Advantages are a fast and easy installation and assembly. With the hinge pin mechanical fastening system ERO Joint® HP, you will optimize your production downtime by reducing the repair time. Mechanical strength and lifetime are higher than any other mechanical fastening systems. Mechanical resistance and elongation are equivalent to welded belts. TENSIONING TOOL FOR ERO JOINT® HP Alternatives Spiral seams The mechanical spiral seams system is also very easy to assemble as ERO Joint® HP but its mechanical resistance is poor. Pin Joint The mechanical Pin Joint system is more difficult to assemble than ERO Joint® HP. The mechanical resistance is also lesser than ERO Joint® HP.

Request for a quoteTanals undertaken Alsatian revolutionizes the process of realization of a dismountable mechanical junction for the toothed belts polyurethane and the bands transporteuses. ERO Joint® used in breakdown service or in a durable way, makes it possible to replace your belts very quickly. This kind of junction is realizable in any toothed belt of step equal to or higher than 8mm. Our research service and Development have all the means of calculation and d' test to dimension your transmissions or to develop the products adapted to your application.

Discover the comparison ERO Joint® HP & Pin Joint in video : https://www.ero-joint.com/en/comparison-ero-jointr-hp-pin-joint

Manufacturer/ Producer

5, Place des Alliés

68290 Masevaux - France