- europages

- >

- Machine tools- metal machining - parts and accessories

- >

- STARRAG GMBH

- >

- Ecospeed From 2570 Up To 25220

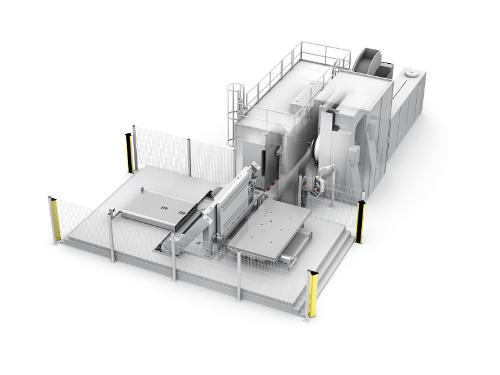

Ecospeed From 2570 Up To 25220

Description

In the aviation industry, there is an increasing trend towards larger and larger monolithic structural components. The ECOSPEED series, featuring a horizontal spindle and a vertical pallet arrangement, has been specially developed for highspeed machining of these large structural aluminum components. A pallet transport system feeds pallets to the machine, the storage station and the loading/unloading station. The innovative Sprint Z3 parallel kinematic machining head, provides the user with the optimum 5axis simultaneous machining process. At a maximum cutting volume of up to 8,000 cm3/min, the machine concept is the world's most productive solution for cutting aluminium structural components, drastically cutting both production times and costs.

- Machine tools, metal machining - parts and accessories

- Transport System

- Pallet System

- Pallets Machine

Product characteristics

- Length (X-axis)

- mm 7,000 - 22,000

- Width (Y-axis)

- mm 2,000 / 2,200 / 2,500

- X-axis

- mm Pallet lenght (X-axis) +900

- Y-axis

- mm 2,200 / 2,500 / 2,600

- Z-axis (spindle horizontal pos.)

- mm 670

- Z-axis (spindle +/- 45°)

- mm 370

- A/B-axis, conical work envelope

- ° +/- 45

- Pallet changing time (definend cycle)

- sec 150 (Values for type 2570)

- Chip to chip time (definend cycle)

- sec 15 (Values for type 2570)

- Acceleration / deceleration in X-axis

- m/s2 9.81

- Acceleration / deceleration in Y-axis

- m/s2 9.81

- Acceleration / deceleration in Z-axis

- °/s2 685

- Acceleration / deceleration in A- and B-axis

- m/min max. 65

- Rapid traverse / feed in X-axis

- m/min max. 65

- Rapid traverse / feed in Y-axis

- m/min max. 65

- Rapid traverse / feed in Z-axis

- m/min max. 65

- Rapid traverse / feed in Bt-axis

- rpm 20

- Tool magazine

- WERO rack type 90 / 125 pockets

- C-axis

- ° 360 continuous

Similar products

NOVOSIM

Turkey

A Pallet Stacking Machine automates the process of palletizing goods, enhancing efficiency in warehouse operations. This machine is designed to stack products onto pallets systematically and securely, minimizing manual labor and optimizing space utilization. Equipped with advanced robotics and conveyor systems, the Pallet Stacking Machine offers high-speed and precision palletization capabilities. It ensures uniform stacking patterns and proper weight distribution for safe transportation and storage of goods. The machine's intuitive control interface allows for easy programming and adjustment of stacking parameters. It can handle a variety of product sizes, shapes, and weights, making it versatile for diverse manufacturing and distribution environments.

Request for a quote

HO-MA GMBH

Germany

Multitrack conveyor belt Different directions possible Buffering option with simultaneous discharge

Request for a quote

KOVINOPLASTIKA LOŽ D.O.O.

Slovenia

Efficient assembly of components assured with 20 automatic lines, 10 manual lines and committed team of experts. Adaptable due to different type of lines: Assembling machines with palette systems, Automatic machines with round table, Machines for riveting, Semi-automatic devices for assembling.

Request for a quote

METAL IN LTD

Bulgaria

Our modern turning machines with CNC controls of company “Mazak” can work details from all types of steels, crude iron and non-ferrous metals. The maximum diameter of working detail is 380 mm, at maximum length 1000 mm. The machines are equipped with devices for the filing of rods. Our products are intended for the automotive industry, machine building industry, construction and other industries. The main details which we produce are: Different types of nozzles for hydraulics and Pneumatics Parts of antivibration elements Turning details about safety pneumatic valves Details for machine building industry Axles and shafts, bushings Bearing units for agricultural machinery

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free