FLUKE PROCESS INSTRUMENTS GMBH

Germany

Manufacturer/ Producer

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Thermalert 4.0 infrared temperature sensors provide accurate temperature measurement from -40 °C to 2250 °C (-40 °F to 4082 °F) for a wide variety of process control applications. • Durable stainless steel IP65 / NEMA4 enclosures designed to withstand ambient temperatures from -20 °C to 85 °C (-4 °F to 185 °F) • Integrated laser sighting • Galvanically insulated outputs • Plastic lens option for food applications • Analog input for ambient compensation and adjusting emissivity setting • Multiple interfaces – 2-wire loop powered for analog and digital communication – 12 wires M16 and 6-pins terminal block for digital communication (RS485) • USB for easy setup • Simple, two-wire or digital installation • Advanced signal processing • Wide choice of focus distances • 2-year guarantee The program includes various models and accessories. The DataTemp® Multidrop software enables easy configuration and process monitoring on a real-time graphical display.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Raytek GS150 thermal imaging systems enable automated quality control in glass bending, forming, annealing, and tempering processes. The GS150LE variant is especially designed for Low-E (low emissivity) glass / one-side coated flat glass. It features automatic emissivity correction. The systems are based on the Raytek MP150 infrared line scanner, which has a max. resolution of 1024 points per line, a max. 150 Hz scanning frequency, and an up to 90° wide field of view. SYSTEM PROPERTIES • Automated temperature monitoring • Visualization on PC • Ethernet TCP/IP interface integrated in the line scanning system • PC-independent alarm output • PC-independent analog outputs 3 x 4 – 20mA BENEFITS • Improve profitability and product quality • Reduce set-up time • Detect defects quickly • Automate quality monitoring for ISO9000 • Reduce scrap • Efficiently manage the heat balance in the oven • Automatically adjust the emissivity value when changing glass types or coatings

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Raytek MI3 infrared temperature thermometer is a two-piece system with a miniature sensing head and separate communications electronics. The OEM version allows direct digital communication with the host machine controller without the need for an additional communication box. The innovative multiple sensing head interface, which can support up to 8 individually addressable heads per communication box, reduces sensor cost, simplifies sensor installation and applications troubleshooting, and provides the lowest cost per measurement point. Raytek MI3 ATEX/IECEx certified sensors can be used safely to monitor the right temperature of hazardous areas / processes with explosive atmospheres. All standard MI3 and MI3100 heads can be ordered with optional ATEX/IECEx certification. One specifically provided Ex-proof power supply can be used with 2 sensing heads.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Dedicated temperature profiling solutions for — Anti-reflection coating & Thin-film deposition — Silicon PV manufacturing: contact drying, contact firing — Lamination Benefits — Measure product temperature uniformity across the process chamber(s) — Optimize the process by reducing energy costs and/or increasing throughput — Troubleshoot the process quickly and easily — Track process stability

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

• Real-time thermal imaging, scan speed up to 300 Hz • Up to 1024 measurement points per line • Wide choice of spectral and temperature ranges • High-quality brushless motor (MTBF 40,000 h) • Built-in Ethernet TCP/IP communications • PC independent alarm output • PC independent 4-20 mA interfaces (3 outputs) • I/O module support for up to 10 sectors/zones (PC independent) • Internal Line Laser for accurate alignment • Rugged, waterproof IP65 enclosure • Air purge keeps window free of dirt and condensation • Built-in water cooling for ambient up to 180 °C (356 °F)

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

— Minimize operator intervention with a fully automated and integrated solution — Capture data from inaccessible or dangerous areas to keep your team safe — Monitor sound signature changes in real-time to prevent unscheduled maintenance Visualize the unheard and unseen with the power of acoustic imaging. The SV600 Fixed Acoustic Imager enables users to continuously detect, locate and visualize air and gas leaks or changes in sound signatures before they become costly problems.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq TP6 is the perfect solution for the most demanding high temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Its robust software options also allow you to read information from the data logger in real-time with the optional Radio Frequency (RF) system and USB/Bluetooth connection options. • Available in 10 and 20 channel configurations and two case styles • Water resistant (IP67 rated) • ATEX certified version available, allowing for safe operation in Zone II classified areas • Communication via USB or Bluetooth • Real time telemetry via USB, RF telemetry and Bluetooth* • Alkaline, NiMH and Lithium battery options • Compatible with the Datapaq Insight™ for mobile application

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

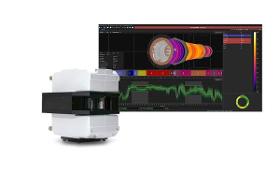

The CS400 Kiln Shell Imaging System relies on the MP Linescanner, which provides continuous, accurate and real-time thermal images and temperature measurements for moving processes. With the ability to scan up to 1024 data points in a single scan, the MP Linescanner can provide a complete picture of even the highest speed manufacturing processes, ensuring an accurate temperature reading. Key Features: — Polar charts highlighting coating thickness and brick thickness — Envelope profiles – including alarm functionality – over the entire kiln — Built-in, on-network storage to store historical data — Free scalable AOIs (areas, line and slice) including temperature trend analysis — Virtual 3D walkthroughs across the entire kiln — 3D views available per each defined kiln zone — Easy-to-use software configurations that showcase the scanner position relative to the kiln — Flexible image sizing and configurable orientations of rotation — Fail-safe “hot spot” alarm outputs

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The ThermoView TV30 thermal imaging camera provides a rich feature set of automation and control capabilities along with the expected durability to meet the demanding industrial applications that FPI product need to survive in. TV30 can interface directly to factory automation equipment, 3rd party software such as Labview, or Fluke Process Instruments ThermoView software. By incorporating a built-in I/O for automation applications in a small foot print, you can expand your field of view by providing continuous infrared images, recording, and actionable analytics right at your fingertips. To meet the factory automation needs of today, TV30 cameras utilize edge technology to provide analytics calculations and on board I/O, multiple fieldbus protocol capabilities to interface to a variety of factory automation equipment, along with high-speed GigE vision capability for the most demanding applications.

Request for a quoteManufacturer/ Producer

Blankenburger Straße 135

13127 Berlin - Germany