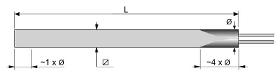

Friedrich Freek GmbH is a family-run company based in Germany. We develop, produce and sell electrical heating elements. As a globally recognised process heating specialist, we have been supplying reliable high-quality products proudly made in Germany from a single source since 1950. Freek supplies its heating elements to renowned companies across a variety of sectors. The manufacturing of highly innovative HotMicroCoils, often employed as nozzle heating elements for hotrunners in plastic injection moulding, is one of our most significant business areas today. However, our customers also benefit from our wide product assortment, which includes all types of industrial heating elements. In addition to the HotMicroCoils, we also supply: Tubular heating elements, heating cartridges, infrared heaters, surface and film heating elements, heating elements for air heaters as well as the accompanying measurement and control technology for this. Thanks to intelligent value creation, innovative production concepts and a wealth of expertise, Freek is able to serve more than 1000 customers each year