FRIEDR. FREEK GMBH - Electric Heating Elements

Germany

Manufacturer/ Producer

FRIEDR. FREEK GMBH

Germany

The IBC/Bpro-Container Jacket Heater is an insulated heater jacket for the heating of bottle-in-a-cage containers. All four sides of the container are covered by the heater. The container heater has two separate heating circuits (top and bottom), allowing for an economical heating of half-filled containers, too. The HILC unheated insulated lid can be used in addition to shorten the heat-up time. The IBC/B heating jacket can also be combined with the IBC/A container base heater. It's a silicone heater mat that is placed below the plastic container before that is filled.

Request for a quote

FRIEDR. FREEK GMBH

Germany

IBC/A-Container Base Heaters are used for the heating of bag-in-box containers. It's a silicone heater mat that is placed below the bag before that is filled. For a faster warming, an additional unheated insulating sheath covering the four sides and the HILC unheated insulated lid can be used. The IBC/Bpro-Container heating jacket as well as the HILC unheated insulated lid are perfect means to support the IBC/A base heater. Using the base heater together with the heating jacket and the insulation cover accelerates the heating process and to reduces heat losses.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Square stainless steel tubular heaters BASE-flex (1.4541) are a reliable industry standard for the use in heating platens and manifolds. In contrast to traditional tubular heaters with a round section which have to be bent by machines, square BASE-flex can be fitted into any rectangular groove with simple hand tools. Moreover, the square shape results in a bigger heat emitting area of up to 80% compared with a corresponding round section. Finally, the easy manual mounting saves the usually high technical expenditure for casting-in / soldering / cementing of bent round tubular heaters. A soft version of the BASE-flex, the NICKEL-flex (2.4068) is available as special execution. Due to the soft, easy to form nickel material, the NICKEL-flex is suitable for manual mounting with hand tools in round sections, too. Furthermore, Nickel has a better capability to conduct heat compared with stainless steel.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Screw-in Tubular Heaters are the standard solution for all heating processes with liquids or gas. The heater is installed in a tank or a tube system by the G1½" screw fitting. The IP54 connection head, fitting and tubular heater consists of stainless steel. The tube sheath material 1.4529 is resistant to sulphite, phosphors and hydrochloride media.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Finned Tubular Heaters are the ideal solution for air or gas flow heating processes. The ribs enlarge the heat-releasing surface significantly. Basis of the finned tubular heaters are our 8.5 mm tubular heaters. The outer diameter of the fins is 28 mm. The elements can be delivered straight, U-shaped or circular (special design on request). Tubular heater as well as fins are made of stainless steel, the standard for the tube is 1.4828 (other materials possible as in chapter Round Tubular Heaters), the fins are normally made of 1.4301 (1.4571 on request).

Request for a quote

FRIEDR. FREEK GMBH

Germany

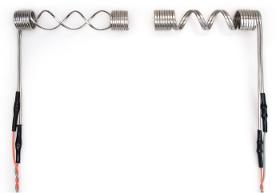

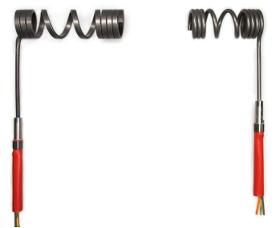

Owing to their small cross-sectional dimensions, MicroCoils are most often connected at both ends and do not permit the addition of a thermocouple. We prefer to use nickel as the sheath material here because it combines the best thermal conduction properties, high corrosion resistance and excellent deformation properties. To ensure that the standard 1000 mm PTFE-insulated connection cable can be positioned at one end, despite the standard two-ended connection of the element, in most cases the MicroCoil is formed into a hairpin shape and wound/laid in a bifilar (parallel) format. Our unformed MicroCoils are also supplied in the hairpin bend shape as standard.

Request for a quote

FRIEDR. FREEK GMBH

Germany

HotCoils have a larger cross-sectional area and are thus capable of greater power than MicroCoils. For this reason they are used in hot runners with adequate space and where high heat densities are required. Owing to the large number of variants and for cost reasons, the sheath material for HotCoils is stainless steel - the standard for the market and thus also for Freek. HotCoils are large enough that thermocouples can be integrated into them. Our standard here is Type J (Fe-CuNi; red/blue), while Types J and K are also available conforming to the IEC and ANSI standards (see colour codes). Since the measurement point of a built-in temperature sensor is situated in the heater and never where the heat is actually required, a HotCoil with a thermocouple makes particular sense where the application allows the use of larger processing (temperature) windows or where the installation location or the design requires protection against overheating.

Request for a quote

FRIEDR. FREEK GMBH

Germany

HotMicroCoils have an exceptional capacity for being shaped - even in three dimensions. Many special winding patterns and geometries apart from the purely cylindrical are thus possible, allowing heating close to the contours of all manner of surfaces. Applications include hot runner manifolds, heating plates and hot die stamps. The shaped heating elements thus obtained can be used in two principal ways: either placed over the surface to be heated (firmly bonded by soldering, force-fitted, pressed or otherwise appropriately joined) or pressed into a positive fit in grooves in the surface to be heated. The second of these alternatives is also becoming more widely accepted in plastics processing, as it offers the best heat transfer because the heating area is the greatest (see also Freek Heat Transfer System). Since not all our customers have the necessary equipment and experience to press the HotMicroCoil elements into the contours of the surfaces, Freek also offers this as a service.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The Freek heat transfer nozzle heating system especially addresses manufacturers and users who operated their hotrunner nozzles with cast-in heaters in the past and would like to stick to their engineering know-how without paying the high price of this former heater design. The standard material of our Freek heat transfer nozzle heater alternative is brass, with or without coating, preferably with a slit. The slit allows the assembly of an external bendable thermocouple and facilitates the disassembly, e.g. in case of a revision and can be coiled over. This is not possible at competitor's nozzle heater solutions. Freek's tight coiling at the heater's ends provides a maximum possible power concentration (patented).

Request for a quote

FRIEDR. FREEK GMBH

Germany

Characteristics of our HotMicroCoils with reflection tube are easy mounting and variable heat distribution. Because of its direct touch and toleranced fit, the sleeve coil heater allows a very good heat transmission to the nozzle. In all our HotMicroCoil heaters with reflection sleeve the assembly of a thermocouple is possible and recommended for bigger diameters and power.

Request for a quoteManufacturer/ Producer

Sudetenstraße 9

58708 Menden - Germany