FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Manufacturer/ Producer

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PUS OPEN is a further development of the dense design. Here the aluminium core is coated alternately with a long and short polyurethane foam lamella. The overall height of the coating is also adaptable to the respective application and is therefore variable (standard: 35 mm). Because of the variant of the open design, the abrasive belt can better cool because the heat from the belt sanding process is better dissipated. Through the precise adaptation of the extremely soft running cushion to the workpiece that shoud be found it is possible to achieve high-performance results when finish grinding. Advantages The contact wheels of the FAPI-PUS – series are coated only with polyurethane foam lamellae. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PUS/KS is an extremely soft version of a contact wheel with a polyurethane foam and plastic foam lamella coating. The overall height of the coating must also be selected based on the respective application. The alternating polyurethane and plastic foam lamellae make the contact wheel extremely soft and particularly adaptable. In practice, this contact wheel is used mainly for the finishing of strongly cambered or rounded workpieces. Because of the different material densities and the spacing between the lamellae heat dissipates very well during the grinding process. Advantages The contact wheels of the FAPI-PUS – series are coated only with polyurethane foam lamellae. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Uniformly wide polyurethane lamellae are attached in precisely established spacing while plastic foam lamellae are attached in the spaces between them to the aluminium hub of the frequency damped contact wheel FAPI-KS/V FREQUENCY DAMPED. The height of the coating resp. the length of the polyurethane and plastic foam lamellae can be varied depending on the application (standard: 25 mm). The positioning of the lamellae dampens the howling sounds in the upper frequency range in the contact wheel coating during grinding so that they are no longer audible to the human ear. The contact wheel FAPI-PUS/KS frequency damped achieves a significant reduction of the noise level in the workplace and so contributes its share to work safety. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VU MILLED is the addition to the smooth model. This is accomplished by milling grooves into the coating of lamellae of foamed up Vulkollan®. The overall height of the coating is also adapted to the respective application and is therefore variable. The grooves can be cut into the coating in various widths, depths and angles. Due to the grooves inserted, contact discs with a milled design are significantly more aggressive than contact discs with a smooth design. The aggressiveness effect of the contact disk can be optimized for each application through an optimal groove width-groove depth-web width ratio so that high-performance processes are possible. With this contact disc, too, no signs of fatigue occur after long, intensive use if used properly.The contact discs of the FAPI-VU series are exclusively provided with a coating made of foamed Vulkollan®. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

As the name indicates, the aluminium hub of the contact wheel FAPI-VU SMOOTH is coated with a coating of a smooth lamellae of foamed up Vulkollan®. The coating height can be varied depending on the application. Advantages The contact wheels of the FAPI-VU – series are only coated with a lamellae of foamed up Vulkollan®. Lamellae of foamed up Vulkollan® is cellular Vulkollan®, a polyurethane foamed with water which has very high dynamic properties. Lamellae of foamed up Vulkollan® can be identified by its slightly yellowish colour. Benefits of contact wheels coated with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

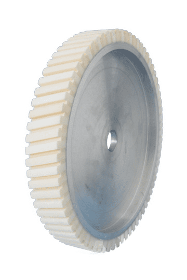

The contact wheel FAPI-VUS OPEN is a further development of the dense model. Here the aluminium core is coated alternately with a long and short lamellae of foamed up Vulkollan® . The overall height of the coating must also be adapted to the respective application and is therefore variable (standard: 35 mm). The open model cools better, or respectively it dissipate heat better. The precise adaptation of the soft running cushion to the workpiece makes it possible to achieve high performance results when finishing. Advantages The contact wheels of the FAPI-VUS – series are coated only with lamellae of foamed up Vulkollan® Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VUS/KS is a version coated with lamellae of foamed up Vulkollan® and plastic foam lamellae. The overall height of the coating must also be selected based on the respective application. The alternating lamellae of foamed up Vulkollan® and plastic foam lamellae make the contact wheel especially soft and adaptable. In practice, this contact wheel is used mainly for the finishing of lightly cambered or rounded workpieces. The different material densities result in the heat generated during grinding being drawn off very effectively. Advantages The contact wheels of the FAPI-VUS – series are coated only with lamellae of foamed up Vulkollan® Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The FAPI–PA MILLED FREQUENCY DAMPED contact disc is the further development of the milled version. Grooves with a groove width-groove depth-web width ratio specially developed by us are milled into the NBR coating of the contact disk. This means that – during the belt grinding process – both the noise level is reduced to a minimum and the material removal rate is increased to a maximum. The total height of the covering can also be selected variably, with the standard height proven in practice being 20 mm. The higher the covering, the more elastic and therefore softer the contact disk surface appears. The contact disks are very aggressive when used due to the grooves they contain. The aggressiveness effect of the contact disk can also be optimized for each application with the milled frequency-damped contact disk by means of an individually optimized groove width-groove depth-web width ratio. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring discs of the FAPI-125 series are the ideal tool for deburring on automatic, stationary deburring machines and are particularly suitable for processing larger series. The shank allows easy mounting and positioning of the deburring discs FAPI-125 on the deburring machine. We will be pleased to advise you which fill variant is best suited for your application. Product features Ultra-fast setup times The shank allows easy mounting and positioning of the deburring discs FAPI-125 on the deburring machine. The selection of different densities, fill lengths, abrasive cloth and abrasive fleece types can have a decisive influence on the deburring process. The optimum design of the deburring discs FAPI-125 can be determined from the process parameters dry or wet grinding, the material to be processed, the material thickness and the desired surface quality or roughness depth. We will be happy to advise you in order to find a suitable deburring disk for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring grinding discs of the FAPI-150 series are the ideal tool for deburring on automatic and manual deburring machines (e.g. our deburring machine FAPI-STARGRINDER) and are particularly suitable for processing larger series. The 25 mm bore and 4 driver holes enable easy assembly and positioning of the FAPI-150 deburring grinding disk on the deburring machine. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results.

Request for a quoteManufacturer/ Producer

Heinrich-Schicht-Strasse 7

42499 Hückeswagen - Germany