- europages

- >

- Radiators - fin-type

- >

- NC MANUFACTURING AND ENGINEERING

- >

- Finned Tube Radiator

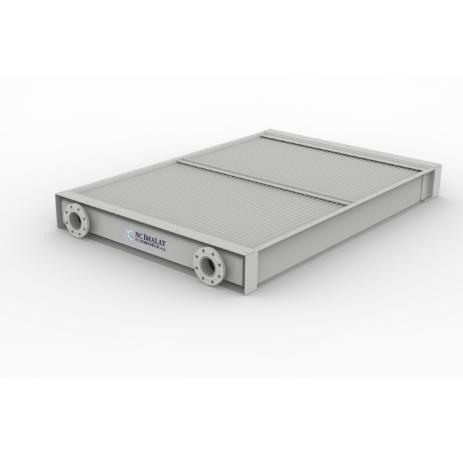

Finned Tube Radiator

heat exchangers

Description

Heat transfer between a gaseous media and a liquid finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air, steam) and a liquid (for ex. water, seawater, oil) takes place in the air-/water heat exchangers. Very often air/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube radiators can also be used as air heater, air cooler or condenser To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. The great increase of the thermal efficiency when applying fin tubes allows a substantial reduction in size and costs of such cooling equipment. The surface of such tubes is substantially increased and consequently less tubes are required compared with exchangers with plain tubes.

- Radiators - fin-type

- Finned Tube

- Cooling Equipment

- Serpentine

Similar products from NC MANUFACTURING AND ENGINEERING

NC MANUFACTURING AND ENGINEERING

Turkey

Double tube heat exchangers (also known tube-in-tube) are designed whereby one tube is concentrically positioned within a larger tube. The double tube composition allows for unrestricted flow of product, making it the ideal heat exchanger for viscous products. The product flows through the inner tube and the service fluid flows through the surrounding shell.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

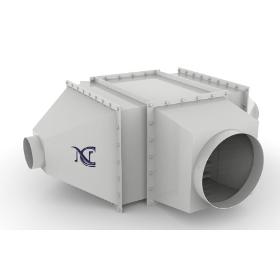

Recuperator systems are heat exchangers that produce hot air by utilizing the energy of high-temperature waste flue gas generated in furnace systems, boiler systems and various processes. Recuperators various heating needs of facilities such as combustion air preheating and ambient heating are met and energy consumption is minimized. Compared to economizers, they have larger surface area and dimensions at the same heat capacity. They can be manufactured as finned tube and straight tube. Recuperator heat exchangers can be made from numerous materials steel, stainless steel and other special materials.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

We are specialized to design and fabricate carbon, stainless or exotic steel pressure vessels mainly for oil&gas, petrochemical and power industries in accordance with ASME Sec VIII Div.1 and EN Norms with CE mark. Most of the industrial processes need to store fluids and materials of different kinds and with different purposes.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

We design and manufacture products based on the project sent by our customers or according to customer requirements. Calculations, designs and projections according to customer demand and in accordance with ASME Code Section VIII Div 1 and 2 (American Society Mechanical Engineers), API 661, API 650 (American Petroleum Institute), TEMA (Tubular Exchanger Manufacturers Association), AD-MERKBLAATTER, CODAT, DIN, EN 13445, PED 2014/68 / AB and TSE. The most common processes in the Oil & Gas, Petrochemical & Chemical, Food & Beverages and Heavy & Light Industry require a significant number of equipment to exchange heat or to storage different fluids or components. The fluid can be either liquid or gas, and one of each flows into the tube and the other flow out of the tube is used to boil, condense or cooling the fluid.

Request for a quote