- europages

- >

- Milling - machine tools

- >

- GEBR. HELLER MASCHINENFABRIK GMBH

GEBR. HELLER MASCHINENFABRIK GMBH - 360° solutions from HELLER for successful future manufacturing

Germany

Manufacturer/ Producer

Product catalogue preview

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

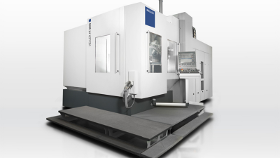

4-axis horizontal machining centres for highly productive machining in all disciplines Tailor-made off the peg for you: modular machine series offering unbeatable productivity at unique load capacity. Highlights Unrivalled long tool life, reduced energy consumption and costs due to realistic dynamic rates High performance and precision from light-metal machining through to heavy-duty machining For varying batch sizes and a variable range of parts and materials HighSpeed Cutting, heavy cutting, dry or MQL machining at full productivity Advantages Fully customisable to your requirements in terms of spindle, spindle taper, tool magazine and chip disposal Attractive price/performance ratio Highest load capacity and reliability High availability thanks to sophisticated safety concept and HELLER services

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for powerful complete machining Setting standards in 5-axis: 5-sided and 5-axis simultaneous machining in HELLER quality Highlights Maximum output at optimum quality due to HELLER's extensive process experience Higher availability thanks to adequate speeds and proven HELLER components Innovative spindle technology in three variants providing optimum process stability (swivel head with PCU 63 or SCU 63, fork head with PCT 63) Two control options: Heidenhain iTNC 530 or Siemens Sinumerik 840D sl Advantages Reduced costs thanks to flexible complete machining Optimised life-cycle costs due to innovative manufacturing concept Two machine variants for maximum manufacturing flexibility: workshop machine FT (table loading) for machining of individual parts in tool and die manufacturing and production machine FP (pallet changer) for series production

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for milling and turning operations HELLER process competence at its best: machine series providing unique cutting performance for milling and turning operations Highlights Combined Processing: milling and turning on a single machine Tool provides 5th axis: 5-axis machining, horizontal, vertical and tilted turning High precision and cutting forces for turning operations due to specific spindle fixation Rotary table with direct torque drive Integrated balancing function Advantages A one-off investment that ensures flexible production today and in the future One machining centre for all machining tasks Two machine variants (CP/pallet changer or CT/table loading) providing maximum flexibility for use Typical HELLER performance for milling and turning operations Reliable productivity thanks to HELLER services

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

Innovative manufacturing solutions for the production of light-duty to heavy-duty automotive components. Automotive components and engines considerably vary in size: from small 0.9L 2-cylinder through to 16L V-8 engines. To provide tailored solutions for these components, HELLER consistently focuses on manufacturing systems in modular design. In addition to the “classic” machining centres from the H, F and C series and the RFK/RFN/DRZ machines for crankshaft and camshaft machining, we are offering the following manufacturing solutions: Highlights Wide range of machine technology Model ranges in modular design From stand-alone machine through to fully automated manufacturing system Comprehensive manufacturing solutions Complemented by all services required for the operation of the machinery Advantages For flexible series production For maximum productivity For minimal piece-part costs For a significant reduction of unproductive idle times For highest availability

Request for a quoteThe HELLER group has been able to develop a unique global corporate culture in the area of conflict that lies between traditional mid-sized family enterprises and internationally operating providers of innovative solutions for machining production. HELLER has been a successful mid-sized family enterprise for 120 years that remains independent and family-owned. Continuity in leadership and at the shareholder level continues to be the mainstay of the business. In mid 2013, members of the fourth generation of the family became involved in the business. These four great-grandchildren of the company's founder are getting ready to take the company into the next generation. Berndt Heller continues to preside over the supervisory board with no change to his position. An enterprise that began 120 years ago with seven journeymen and three apprentices has grown into an internationally operating company with over 2500 qualified employees today. It is a business that can be proud of its success story, and one that can set its sights on the future with confidence.

Website

Documents

Welcome to HELLER

Manufacturer/ Producer

Gebrüder-Heller-Straße 15

72622 Nürtingen - Germany

Company info

Key figures

-

- Company headcount

- > 500

Organisation

-

- Year established

- 1894

-

- pages.epage-home.site-status

- Registered office

-

- Main activity

- Manufacturer/ Producer

Activities of GEBR. HELLER MASCHINENFABRIK GMBH

- Milling - machine tools

- Machine tools - metal machining

- CNC router

- milling machines

- cnc tools

- Crankshaft milling machines

- Camshaft circular milling machines

- camshafts

- flexible machining centres

- CNC finishing