- europages

- >

- Grinding - steels and metals

- >

- GIZELIS ROBOTICS

- >

- GRINDING / POLISHING APPLICATIONS

GRINDING / POLISHING APPLICATIONS

Description

Robotic systems assist in such applications thanks to their particularly enabling features. Typical grinding applications include a closed robotic cell to avoid particle dispersion in the surrounding area. A head-bearing robot is located inside as well as various other grinding machines. The robot picks the piece from the feeding area, drives it with precision through all processing stages and places it at the discharge area before it starts all over again by picking the next piece. Depending on the product, a suction system is put in place to keep the robotic cell clean. Robotic grinding is the only option for all related industries since production time is greatly decreased, maximum degree of safety is achieved and, most significantly, it offers flawless quality and consistency to end products. Only companies using robotic systems stand out from the competition, as they can produce optimum products at the lowest possible production cost.

Similar products

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

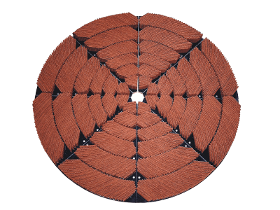

The further development of our deburring grinding plates are our patented deburring segments FAPI-FLEX-SAT (patent no. DE20304860 U1). These advanced deburring segments were developed in collaboration with the company Timesavers from the Netherlands. Fast, safe and clean deburring or edge rounding of sheet metal parts is no longer a problem when using these tools. Deburring grinding segments can also be individually adapted depending on the application. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

MARXAM PROJECT

Poland

The grinding services are a surface finishing process that includes every detail that requires the removal of machining allowance and obtaining large classes of surface roughness. For technological reasons and the number of requirements as to the further condition of the surface of the elements, we adjust the metal grinding process to individual customer requirements. Metal grinding is a finishing treatment involving the treatment of surfaces of various shapes with abrasive tools. Grinding allows you to remove burrs (deburring) and roughness, as well as machining allowance. This surface finishing method allows to obtain a surface with low roughness and desired shapes and dimensions with quite high accuracy. Surface grinding is one of the most common methods of surface treatment, for a wide variety of metals, including grinding steel, metal grinding bits, grinding welds, aluminum grinding and many others.

Request for a quote

ALLIED FOR TECH

Poland

We perform grinding mainly on endless belts, as well as with the use of special grinders and hand-held power tools.

Request for a quote

STALMA S.A.

Poland

Grinding is a precise reduction machining done with the use of griding wheels on special machines that is centreless grinders. Ground bars are characterized by the highest quality among bright steel products and find the application in the production of the most responsible parts of the machinery. Ground bars can be processed from both half-products, drawn or peeled bars. Mechanical properties do not change during grinding.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free