- europages

- >

- Measurement and control instruments

- >

- MAHLO GMBH & CO. KG

- >

- Graviamt FMI-15

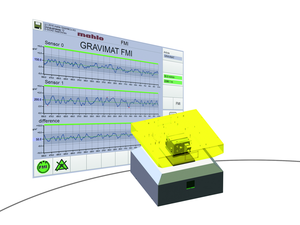

Graviamt FMI-15

Sous-titre 13

Description

Transmission of beta rays The weight monitoring and control system measures the weight continuously, without contact, destruction-free and on moving product. The measurement is based on the attenuation of rays from a radioactive isotope through the substrate located in the measuring gap. This attenuation in intensity is an indication of the weight of the product.

- Measurement and control instruments

- process control

- Basis weight

- Beta gauge

Similar products from MAHLO GMBH & CO. KG

MAHLO GMBH & CO. KG

Germany

Control of thread density / course density / basis weight The Famacont PMC determines the thread density by means of a non-contacting, optoelectronic or imaging process. With the optoelectronic process individual threads or courses pass the sensor and are projected onto the photocell using a precision optical lens. The resulting frequency is proportional to the thread count. A high-resolution camera is used with the imaging process. The image is analysed with using suitable software (FFT analysis). Both, the thread count in weft and warp direction can be determined here with maximum precision.

Request for a quote

MAHLO GMBH & CO. KG

Germany

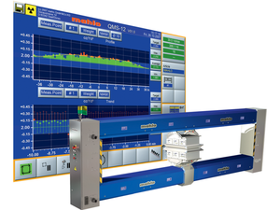

Web process control The Qualiscan QMS is a modular system for measuring, logging and controlling critical process parameters over the entire width of the product, including basis weight, coating weight, thickness, moisture etc.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Measurement of steam Much unused energy is wasted through the exhaust air during drying processes without appropriate control. The Ecomat AML optimises the heating energy required by monitoring charging of the exhaust air with water steam and controls this factor through the fan speed or the exhaust air vent control.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Ionisation of the air The Antistat AMW ioniser for trouble-free processing of synthetic materials and of textiles with high charge separation. By ionising the ambient air, the electrostatic charge is diverted from the product sheet. Antistat AMW can be used at high or low speeds.

Request for a quote