HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Manufacturer/ Producer

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Made for the gear-cutting sector Clamping solutions for the gear-cutting sector are individual and have very special requirements. Consequently, it is not easy to find the suitable clamping device, particularly in the case of high variant diversity and smaller lot sizes. The conventional solution is to use fixtures that are more or less effective. Rigid and narrow standard segmented mandrel Fortunately, this is now history. With the MANDO G211 you are relying on a standard segmented mandrel. You profit from in-stock segmented clamping bushings. The rigid and narrow mandrel with optimized tool runout contour is ideal for use in gear cutting applications. Moreover, it can also be used for gear shaping or grinding. Three end-stop levels that are placed with different proximity to the workpiece make it possible to use individual workpiece end-stops. Also a coolant connection ensures process reliability.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

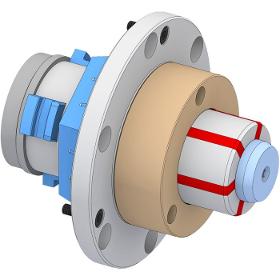

No problem to change-over from O.D. clamping to I.D. clamping Change-over from O.D. clamping to perfect I.D. clamping, without changing the clamping device? No problem with MANDO Adapt: Place the mandrel in the mounted clamping device, tighten three screws, and lock the mandrel in the clamping device. Reduce time In this process the mandrel engages in the coupling of the clamping device via a sophisticated mechanism, where otherwise the clamping head engages. MANDO Adapt is attractive with extreme rigidity and precision. Without adjusting For rotating products, concentricity of 0.005 mm between chuck taper and mandrel taper can be achieved. For stationary clamping devices repeatability of 0.003 mm is possible. And best of all: This can all be accomplished without adjusting.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

You will only get the best results in terms of accuracy with clamping devices that are in top condition. Our new care set will help you here. This includes: 1 x Cleaning spray to degrease 1 x Penetrating lubricant to oil 1 x Grease gun to lubricate / grease 1 x Microfiber cloth to remove chips 2 x Grinding pad to remove rust film 2 x Pairs of safety gloves

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

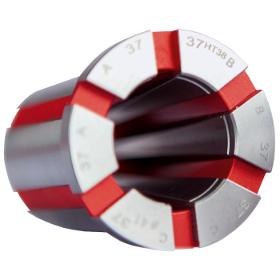

This development represents more than 30 years of SPANNTOP experience. It exploits all the advantages of the latest machine tools. This clamping head is not only extremely powerful, it is also convincing through simple handling. With the changing fixture you set up in no time. The combination of steel and rubber, specially developed by HAINBUCH, in conjunction with a vulcanization that has been perfected over decades, is designed for maximum speed and holding force – with optimal concentricity, and incredible rigidity and service life.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Easy manual actuation The TOROK manual chuck is primarily used in tool prototyping on machines without a clamping cylinder. For example, thanks to its easy manual actuation, when used on grinding machines you can safely and delicately clamp. In combination with our clamping device adaptations, such as the MANDO Adapt mandrel-in-chuck or the jaw module, many more clamping options are possible. Lightweight variant And most recent: Thanks to the optional lightweight CFRP design, with the TOROK CFK you save one-third the weight. This is particularly set-up friendly and it offloads the machine spindle bearings.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Maximum precision in a mini format The TOPlus premium chuck is ideal for high-precision clamping of delicate and thin-walled parts, as well as solid and massive parts. In combination with premium clamping heads and when clamping against the end-stop, you benefit from incredible run-out accuracy of ≤ 5 μm. That makes the standard TOPlus premium chuck a better and less expensive alternative to hydro-expansion and diaphragm clamping devices. In addition to high precision, the large opening stroke also facilitates automated loading of the machine – even if the robot is somewhat inaccurate. By the way, slight contact with the workpiece during loading has no negative effect on the TOPlus premium. Despite its high precision it remains »robust« and your process remains stable. The most accurate of all HAINBUCH chucks!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

In terms of precision, stability, and flexibility the vulcanized segmented clamping bushings are unbeatable. They consist of segments made of chrome/nickel, case hardened steel that is very hard, extremely wear resistant, and rigid [60 HRC]. Plus, they do not have to »bend« to clamp the workpiece. In addition, all functional surfaces are completely ground in one clamping set-up. The result: maximum run-out accuracy, maximum holding power, and long life span.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

No re-clamping It is useful, when you can machine a workpiece over its entire length. It is even more practical, if in addition the re-clamping can be omitted. Firstly, this increases concentric precision, secondly, geometric tolerances are »stabilized«, and thirdly, our face driver adaption is also assembled 1-2-3. Simply insert it in the clamping device, tighten the three screws, and that’s it! Our CENTREX interface ensures perfect concentricity.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

A regular check of clamping force is vital for a safe, precise, and productive process. Do you manufacture at the highest possible metal removal rates? Perhaps your clamping device can do more than you think! Those who face tough competition can no longer afford to manufacture with »theoretical clamping forces«. Nevertheless the DIN EN 1550 requires that static clamping force measurement must be performed by the manufacturer at regular intervals. Modular measuring system The TESTit clamping force gauge measures and records the clamping force for O.D. clamping and I.D. clamping and even the draw-in force of hollow tapered shank locations. TESTit consists of two parts: The basic unit, which is the IT module, and the measuring units, which are the TEST modules. You only need the IT module once – regardless of whether you want to measure the clamping force at O.D. clamping or I.D. clamping or the draw-in force.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Reliable and long life SPANNTOP nova – this development represents more than 30 years of SPANNTOP experience. It exploits all the advantages of the latest machine tools. The components are optimized for balance quality, and have an extended guide length. The clamping length of the workpieces is also significantly greater. This chuck is designed for maximum RPM and holding power at ideal concentricity. It is extremely rigid, precise, and has an extremely long life. Convenient change The position-oriented base end-stop of the »combi pull-back« and »combi deadlength« variants can be conveniently changed from the outside via three clamping screws countersunk in the chuck, and for standard chucks, provides excellent accuracy for face location combined with through-bore capacity. Chuck SPANNTOP nova: reliable and solid. The product is the result of more than 30 years of experience!

Request for a quoteManufacturer/ Producer

Erdmannhäuser Straße 57

71672 Marbach - Germany