Umrüsten mit den Trends der Verpackungsbranche

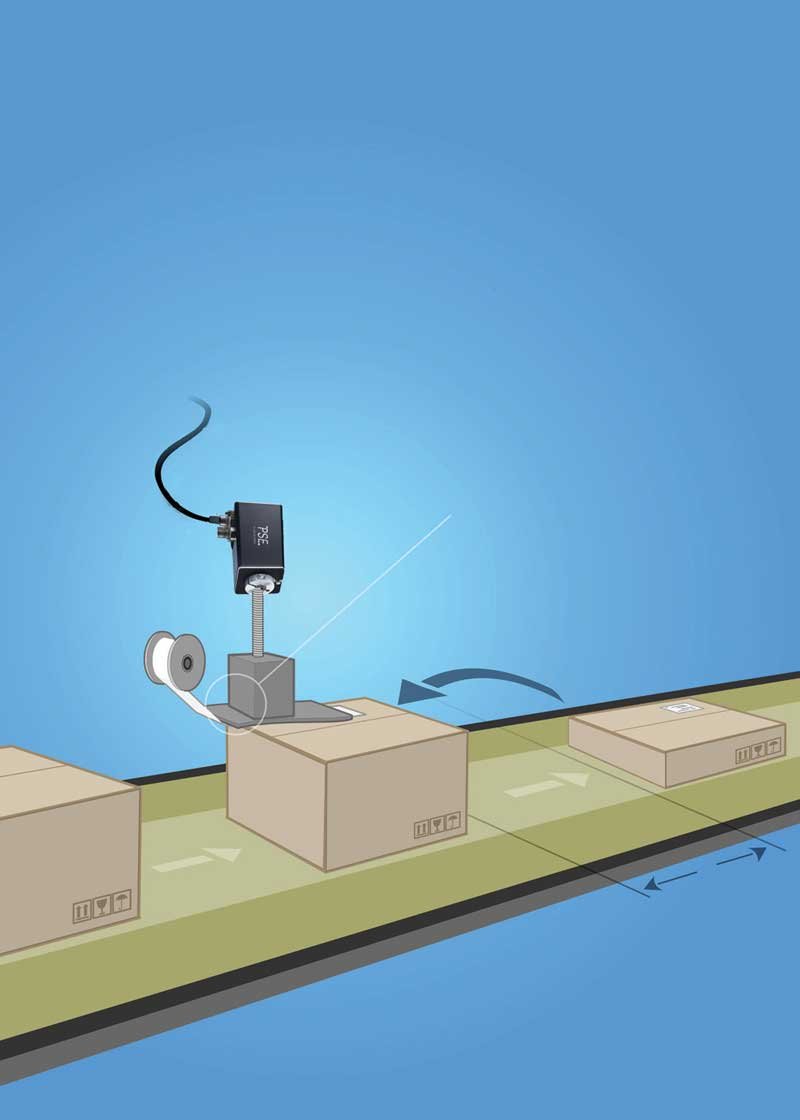

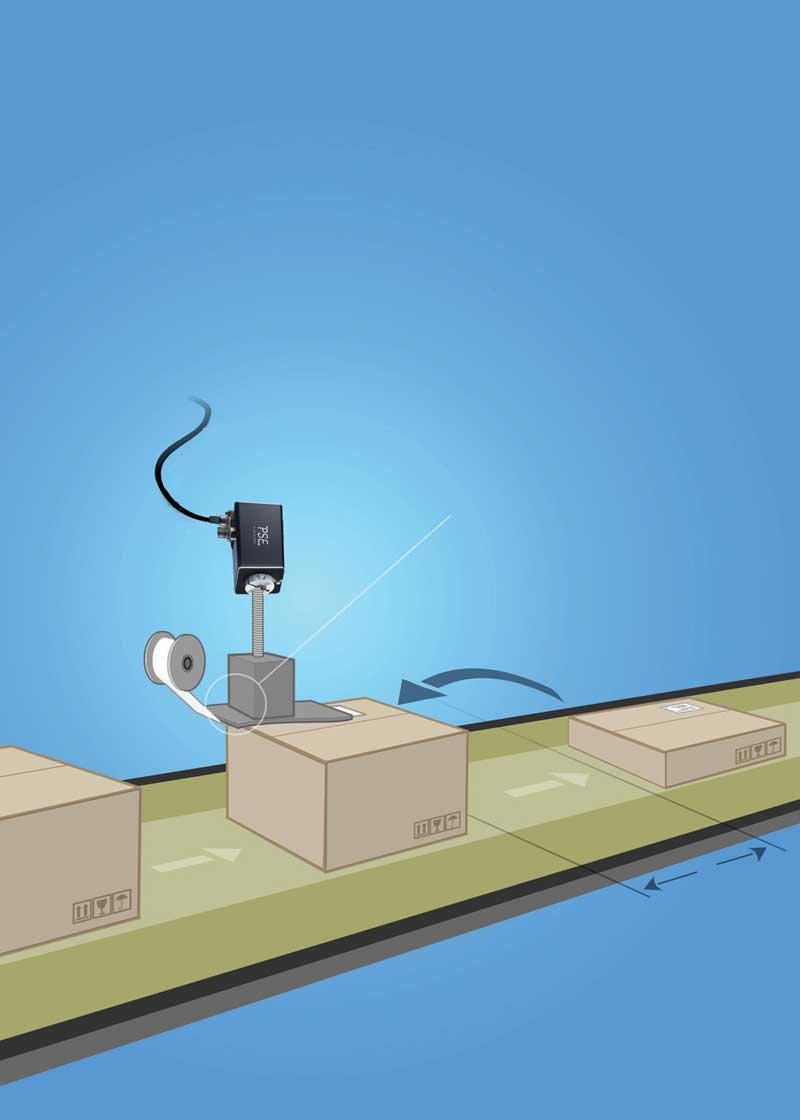

Latest project ・ 20 Mar 2020Nachhaltigkeit Die halstrup-walcher Positioniersysteme funktionieren ohne Batterie und sind wartungsfrei. Das Unternehmen berücksichtigt in seinem unternehmerischen Handeln Umweltaspekte und ist nach ISO 14001:2015 zertifiziert. Industrie 4.0 Die Positioniersysteme von halstrup-walcher können in das Maschinensystem über jede Steuerung eingebunden werden. Die Antriebe stellen ein eigenständiges cyber-physisches System dar. Der absolute Encoder ist der Sensor zur Positionsbestimmung. Getriebe, Motor und Motorsteuerung sind die Aktoren zur Bewegung des Positionierobjekts. Gemeinsam mit der dezentralen Intelligenz lassen sich die Positioniersysteme optimal in die Maschinenabläufe einbinden. Individualisierung Der Trend zur Individualisierung führt zu immer kleineren Losgrößen. Neue Formate müssen schnell eingestellt werden, ohne Qualitätsverlust, reproduzierbar und mit kurzen Stillstandzeiten. Mit den Positioniersystemen von werden alle Achsen zeitgleich eingestellt.