- europages

- >

- Petrochemical industry - installations and equipment

- >

- HEERTECH INDUSTRIAL SERVICES

HEERTECH INDUSTRIAL SERVICES

Netherlands

Subcontractor

Heertech Industrial Services is a company that supplies the qualified personnel you need for your projects. We subcontract them and make sure they have accomodation near the job and transportation to get there. We provide the following workers: MIG-MAG welders, Electrode welders, TIG welders, pipefitters, cabletray pullers, etc. Our main target is strengthening the Dutch market and increasing its activity on the international market, both as a provider of specialized labor, as well as producer / constructor. Over the years, we’ve created some powerful first impressions and through repeat business, we’ve built on those, to forge long lasting relationships. We truly believe that because of our passion, fairness and integrity, we’ve created a company people want to work with.

Website

Company info

Key figures

-

- Company headcount

- 11 – 50

Organisation

-

- Main activity

- Subcontractor

Activities of HEERTECH INDUSTRIAL SERVICES

- Petrochemical industry - installations and equipment

- Instrument Techinicians

- TIG-Welders

- Electricians

- Cabletray Fitters

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

PRAXAS B.V.

Netherlands

Do you always want to be aware of the temperature, humidity and pressure in the area where you live or work? Then the EasyLog EL-SIE-6+ data logger is the perfect solution! This advanced device has everything it takes to monitor your environment and gives you direct insight into the circumstances. With the EL-SIE-6+ you don't have to install complicated software on your PC or Mac. The device already has everything on board to get started right away. Connect the data logger with a USB cable and configure the device via your web browser. This way you can quickly and easily view, analyze and download your data

Request for a quote

PRAXAS B.V.

Netherlands

The LogTag TRID30-7R Temperature Logger WHO with Display is a temperature recorder specifically for monitoring the storage conditions of vaccine refrigerators, retail areas and medical facilities.

Request for a quote

PRAXAS B.V.

Netherlands

To configure the sensor for use on a given wireless network, either connect it via USB to a PC running EasyLog WiFi software on the network, or configure wirelessly using the EasyLog Cloud app on a mobile phone with access to the network. The sensor can then be placed anywhere within range of the network, In a typical usage scenario, the probe is placed next to the vaccines within a fridge, and the ribbon cable fed out to the logger attached to the outside of the fridge using its magnetised wall bracket; the cable is deliberately thin so as not to interfere with the fridge seal. If the sensor temporarily loses connectivity with the network, it will log readings until it is able to communicate again with the PC application or EasyLog Cloud (max 30 days at 10 second sample interval).

Request for a quote

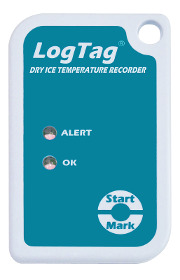

PRAXAS B.V.

Netherlands

With a size of a credit card, the temperature recorder is easy to hang. The LogTag TRIL-8 Dry Ice Temperature Logger measures and logs up to 8,000 temperature readings in a range of -80°C to +40°C (-112°F to +104°F). This makes the temperature logger ideal for monitoring transport that must be kept at low temperatures, such as cargo containing refrigerants with dry ice.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free