HUGO BECK MASCHINENBAU GMBH & CO. KG - COMPLETE SOLUTIONS FOR HORIZONTAL PACKAGING IN FILM & PAPER

Germany

Manufacturer/ Producer

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

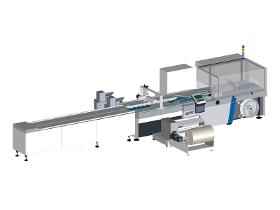

The intermittent Form Fill and Seal Machine flexo 500 scores with maximum versatility and flexibility even in its basic configuration. Whether frozen pizzas, biscuit boxes, fruit and vegetables, books, skis, laminates or various household goods, etc., you are instantly equipped for any kind of application with this machine – daily changing orders, for example. The flexo 500 features a side-sealing unit. The transversal sealing unit is designed as an intermittent version and processes a wide range of films and product dimensions

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The intermittent Form Fill and Seal Machine flexo 700 scores similarly to the basic modell flexo 500 with maximum versatility and flexibility, but is designed for the packaging of large format products with a width of up to 620 mm. Whether shoe boxes, boards, shelves, ladders, ironing tables, large calendars, pots, tissue rolls, insulating mats, etc., you are instantly equipped for any kind of large format application with this machine – daily changing orders, for example. The flexo 700 features a side-sealing unit. The transversal sealing unit is designed as an intermittent version and processes a wide range of films and product dimensions.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

With the flexo 700 E-Com you are optimally equipped to meet the demands of e-commerce packaging in film. It is Hugo Beck’s most flexible and efficient machine for these applications. Whether dealing with the direct dispatch of individual goods, packing groups of products or meeting the complex requirements of returned goods packaging, the flexo 700 E-Com packs goods with a minimum use of film, maximising packaging results both with and without shrinking of the film bags. A quick changeover between product batches adjusts the machine o new product sizes or, as an option, the machine can automatically adapt to changes in a product’s length, height or width. Additional options include the ability to add an easy-opening perforation to the bags as well as inserting a double-sided adhesive tape for resealing a bag for returns.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

With the paper e-com fit you are optimally equipped to meet the demands of e-commerce packaging in paper. Whether dealing with the direct dispatch of individual goods, packing groups of products or meeting the complex requirements of returned goods packaging, the paper e-com fit packs goods with a minimum use of paper or film. Both uncoated and coated paper can be used for producing paper bags with two glued or sewn sides plus a top overlap. The shipping bag size is automatically adapted to the dimensions of the product during production. Thus, different product sizes can be packaged in a jumble. Furthermore, the machine offers the possibility of storing two paper rolls of different widths. After the product scan, the packaging machine then decides how wide the paper web must be and can select one of the two paper rolls. This minimizes paper use.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The intermittent Form Fill and Seal machines flexo 500/700 Push are pusher-machines that wrap difficult products with ease, such as glass bottles in bundles or salt and pepper shakers. They collect and group the products in order to subsequently push them into the film. In order to ensure that no products tilt over, our machines maintain physical contact with the articles to be packaged until they are safely in the bag. The transversal sealing unit is designed as an intermittent version and processes a wide range of films and product dimensions. The packaging styles features a bottom overlap.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The high-performance and extremely flexible intermittent Form Fill and Seal machine flexo H is particularly suitable for film packaging of wood and similar long parts from 800 mm in length, such as parquet or laminate, mouldings, wood or laminated wood, furniture parts or doors. It takes just five minutes to deal with a pallet of laminate. Similarly, our flexible packaging machines are ideal for similar length products, including skis and snowboards, spirit levels, rolled goods, steel pipes, and many more items.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

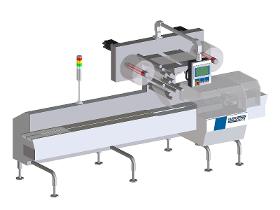

The continuous Form Fill and Seal machines of the servo X series are available in five performance ranges and numerous variants. They cover the broadest possible range of horizontal film packaging applications for various industries – and all this with maximum modularity. The machines can be configured individually and thus meet all requirements for the desired performance or type of packaging. Depending on the machine variant, several packaging styles can be flexibly produced with one machine. Whether chain infeed or infeed conveyor, servo X machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %. This ensures that the film packaging‘s excellent appearance is unrivalled.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The continuous Form Fill and Seal machines servo X 800 are the most flexible and powerful of film packaging machines in the large-format segment – and all this with maximum modularity. The machines can be configured individually and thus meet all requirements. They are designed for packaging large-format products with a width of up to 800 mm and a length from 150 mm. Whether chain infeed or infeed conveyor, the machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %. This ensures that the film packaging‘s excellent appearance is unrivalled. Depending on customer requirements, these packaging machines are equipped with different control systems.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Paper or film? Stay flexible! A single machine can now deliver both film and paper packaging applications. The continuous Form Fill and Seal Machines paper X hybrid are designed for packaging goods in paper or film. A simple changeover ensures you are ready for the new product and the new packaging material. Whether using a chain infeed or infeed conveyor, the machines stand apart through their continuous packaging process – without stop-and-go – maximising efficiencies by ensuring there is no downtime when sealing or glueing. Our paper packaging solutions are available in different versions, depending on how flexible you need to be: - the basic model paper X features paper packaging with overlap on top - the paper X hybrid features paper and film packaging with overlap on top - the paper X hybrid advance features paper and film packaging with overlap on top and side seal

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Our fully automatic flowpack machines are suitable either for high-speed applications or airtight packaging requirements, depending on the version selected. The machines feature either rotating or box motion transversal sealing units, with selection of a longitudinal seam either above or below. Each machine can be combined with a wide range of feed systems, such as finger conveyor chains or infeed belts. With our ability to handle everything from PP or aluminium laminated films through to Tyvek® – anything is possible. PE-coated paper can also be used for flowpack production. Our flowpack machines are also available as hygienically designed versions.

Request for a quoteManufacturer/ Producer

Daimlerstr. 26-32

72581 Dettingen/erms - Germany