Heat staking

Heat staking

Description

The riveting process creates irresolvable interlocking bonds. This is achieved by forming or reforming of thermoplastics. In most cases in this procedure only point-shaped or segmented joints are realized. In contrast to welding of two components there cannot be achieved hermetic joints. A particular version of this procedure is the bonding of plastics with metals, textiles and cardboard. The method is frequently used for wooden decoration parts, into which a chrome decoration strip has to be embedded. As a rule the hot form riveting is carried out in a one-cycle process. A heated riveting stamp forms the riveting head under pressure. After forming the stamp is shortly cooled down in order to avoid adhesion of the plastic material on the thermal riveting stamp. After this short cooling phase the riveting stamp is again moved above.

- Thermoforming, plastics - machinery

- Thermal procedures

- Heat staking

- Thermal riveting

Similar products

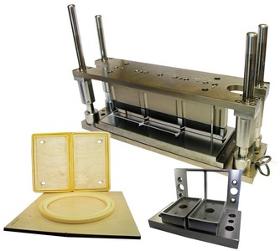

PRO COUPE INDUSTRIES

France

Thermoform tooling for ULMA®, MULTIVAC®, MECAPACK®, CFS® TIROMAT®

Request for a quote

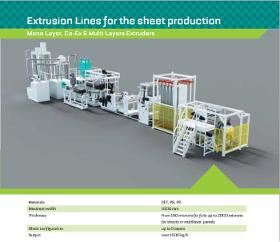

KUZEY GLOBAL

Turkey

Extrusion lines for thermoforming plastic products

Request for a quote

KUZEY GLOBAL

Turkey

Thermoforming machines for disposable food cups and sheet line extrusion , ofset printing machines

Request for a quote

TECHNIC MACHINES

Turkey

We supply our plastic thermoforming machine for different product solution. For example cup, dish, plate, lid, bowl, medical, clamshell etc. We have also different production capacity options on our thermo molding machine. We supply the quality, international standards and performance together with our plastic thermoforming machines. You will have high production capacity with low power consumption with our thermoforming machines, with our advanced software and technology. You can achieve easily to European Quality Level on your products, with the help of our European technology. Just contact with us for your thermoforming machine research, we will provide the optimum solution for your machine research.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free