- europages

- >

- Ceramics- refractory

- >

- XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

- >

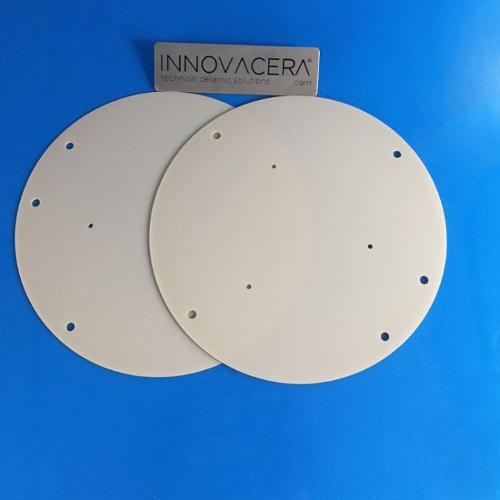

- High Thermal Conductivity AlN Aluminum Nitride Ceramic Disc

High Thermal Conductivity AlN Aluminum Nitride Ceramic Disc

Description

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

- Ceramics, refractory

- Aluminum Nitride Ceramic Disc

- High Thermal Conductivity Ceramic Disc

- AlN Ceramic Disc Plate

Product characteristics

- Thermal Conductivity:

- 170W/MK

- Surface roughness:

- 0.3-0.5

- Compressive strength:

- 2500 Mpa

- Bulk Density:

- 3.30g/cm3

- Flexural strength:

- 280 - 350 Mpa

Similar products from XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

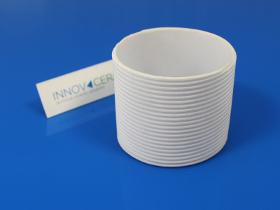

Alumina ceramic (Aluminum Oxide or Al2O3) is an excellent electrical insulator and one of the most widely used advanced ceramic materials. In addition, it is extremely resistant to wear and corrosion and is an industrial ceramic that can only be formed by diamond grinding. The melting point is very high at 2,072°C, and it is very hard. Alumina components can be widely used in electronics, pump components and automotive sensors.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA is good at yttria stabilized zirconia. Unlike other ceramic materials, zirconia is a material with very high resistance to crack propagation. Zirconium oxide ceramics also have very high thermal expansion and are therefore often the material of choice for joining ceramic and steel. > high fracture toughness > thermal expansion similar to cast iron > extremely high bending strength and tensile strength > high resistance to wear and to corrosion > low thermal conductivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Typically ceramic bolt and screws are used in low-stress & high temperature conditions. These conditions are most commonly found in electronic equipment, where ceramic screws are particularly attractive due to their lack of electrical conductivity. Another benefit of ceramic screws over polymer based ones are that they have much higher and longer lasting performance due to their ability to withstand sustained heat cycling. Supply in M2x5, M3x10 and M4x10 screws with nuts, customized size is acceptable.We recommend to use the screws only together with the supplied nuts. The usage with metallic threads might not fit as the ceramic parts are manufactured in moulds and reach their final dimension after sintering. Hence they have other tolerances than metallic threads. >Thread Specification:M3-M24 >Screw cap:Hexagonal socket, flat head >Plain Ceramic Hex M3 x 10mm Set Screw >Made from alumina ceramic >Suitable replacement for plastic screws to solve embrittlement or creepage problems

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia (ZrO2) Ceramics have the highest toughness and strength at room temperature of all the advanced ceramic materials. At present, it has been widely used in grinding balls, dispersion and grinding media, nozzles, ball valve seats, zirconia molds, micro fan shafts, optical fiber pins, optical fiber sleeves, drawing dies and cutting tools, wear-resistant knives, and other room-temperature resistant Grinding parts and so on. Zirconia is widely used in the fields of the thermal barrier layer, catalyst body, medical treatment, health care, textile, and so on. This dense advanced ceramics material is usually precision ground using conventional diamond cutters and wheels. Machines used for precision grinding include: * Surface grinders * CNC milling machines * Jig grinders * Centerless grinders * CNC lathes * ID grinders

Request for a quote