- europages

- >

- UNEX HEATEXCHANGER ENGINEERING GMBH

- >

- High quality - High performance fully welded heat-exchanger

High quality - High performance fully welded heat-exchanger

UniWeld - Hybrid

Description

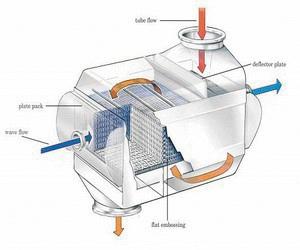

The UniWeld combines the advantages of conventional shell and tube heat-exchangers with spiral and plate heat-exchangers due to its design and construction. This mixed construction is based on the design of the heat-transfer channels, which are on one side in the tube design and on the other side in a plate heat-exchanger. UniWeld Hybrid exchangers utilise in this way the advantage of tubular heat-exchangers (high temperature, pressure resistant and solid construction) and plate heat-exchangers (high heat transfer, minimal space and low logarithmic temperature difference) in a compact system. Other advantage compared with gasketed plate heat-exchangers is the safe splitting of the 2 media at pressures up to 80 bar and between -200°C and +900°C.

Product characteristics

- -

- pressure from vacuum up to 80 bar

- -

- high heat transfer coefficient

- -

- compact design

- -

- plate thickness 0.4 mm to 1.0 mm

- -

- low pressure drop

- -

- heat transfer surfaces 2-10,000 m²

- -

- construction for individual applications

- -

- low logarithmic temperature differences

- -

- covers can be flanged or welded

- -

- usable in temperatures -200 °C to 900 °C

- -

- possible heat-transfer area 250 m²/m³

- -

- low weight compared to tubular heat-exchangers

- -

- all weldable and pressable materials can be used

- -

- good self-cleaning, due to high media velocities

- -

- good performance for gas, steam or fluid

- -

- use as heat-exchanger, condenser or evaporator

- -

- low product flow times for sensitive products

- -

- fully welded construction without gaskets