- europages

- >

- Infrared tubes

- >

- EUROLINIA

- >

- Industrial Infrared Tunnel Ovens

Industrial Infrared Tunnel Ovens

Infrared tunnel ovens are engineered for a wide variety of applications

Description

EUROLINIA infrared industrial tunnel ovens are designed to rapidly and uniformly heat the surface of cables, wires, polymer pipes and tubes, dry fiber optics and etc. in batch or continuous conveyor production using targeted high-intensity infrared radiation. High efficiency is achieved by concentrating high-intensity infrared radiation and by using a circular reflector that efficiently distributes radiant energy inside the heating chamber. Additional efficiency is gained by installing three-level thermal protection. EUROLINIA tunnels have modular structure: one heating section is 2 meters long, you can connect up to 8 sections in one production line. Maxumum temperarature in the tunnel can reach up to 700C. Tunnels can have multiple separate heating zones and can be equiped with a conveyor. To ensure high-quality, high-precision surface heating, industrial tunnel ovens are also equipped with an automatic heating control system (APCS).

- Infrared tubes

- infrared

- tunnel

- oven

Similar products

FLUKE PROCESS INSTRUMENTS GMBH

Germany

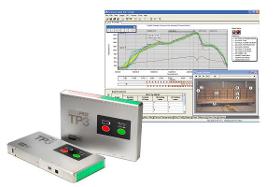

Tunnel Kiln Tracker® temperature profiling systems are comprised of a data logger, a protective thermal barrier and Insight software. Using a Datapaq® system, you can obtain reliable and accurate in-process temperature profiling in tunnel kilns used to fire brick and roof tiles, tableware, sanitaryware, tile, refractory and more. For detailed information, download the Kiln Tracker System brochure. Kiln Tracker Insight Software Insight software takes the data gathered by the data logger, quickly interprets the information, and reports the analysis you need instantly. Wizards walk you through all the major software functions and simplify setups and analysis. Critical profile results are available on one easy-to-read screen, automatically informing you of any out-of-tolerance parameters. In addition, a software alarm warns you immediately of process issues, allowing you to take corrective action before product damage occurs. Features include

Request for a quote

HIMMELWERK HOCH- UND MITTELFREQUENZANLAGEN GMBH

Germany

With our infrared pyrometers you are able to finely control the exact heating of your production processes and guarantee point perfect temeperatures and repeatability of your process.

Request for a quote

GHM MESSTECHNIK GMBH

Germany

Infrared thermometer included Recognition of mould growth, etc. Warning signal Recognises cold and hot bridges

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free