- europages

- >

- Piston pumps

- >

- JERKO-SPRÜHSYSTEME GMBH

- >

- products

JERKO-SPRÜHSYSTEME GMBH

Germany

Manufacturer/ Producer

JERKO-SPRÜHSYSTEME GMBH

Germany

LubriStar PLUS - the solution to comply with occupational safety regulations and the new emission values! With fewer emissions and longer service life, the system pays for itself in a very short time. A well thought-out and modular design allows easy retrofitting to all forging hammers. With our LubriStar PLUS systems, the use of sawdust is 100% unnecessary. Specially developed minimal spray system for the highest demands, whether simple flanges or complex titanium engine blades. Be prepared now for the next certification and score points with this simple and practical solution!

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

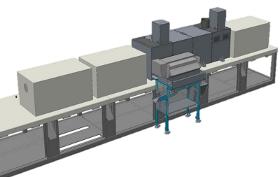

Coating for warm forging and hot forging on hatebur presses. Our modular design kits enable you to safely coat diameters from 15mm to 160mm. A system developed by Jerko is also used to safely coat the front sides. Whether horizontal or vertical coating, with our systems you are always on the right side.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

The revolution in spraying technology! The patent registered single nozzle spray head combines the best of both worlds. Robust, simple and highly flexible in application. Each nozzle spray head can be controlled individually or in groups. Every possible contour can be sprayed - without set-up times. How does it work? The nozzle plate is made by simple stainless steel parts. The nozzles are then individually fixed on a matrix - that' s it! The control can be done in groups or individually - at any time! Every single spray jet can be individually changed by exchangeable nozzle heads. What is the cost? Thanks to the use of the most modern materials and additive manufacturing processes, the nozzles cost only a very low percentage compared to conventionally machined nozzles.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Jerko flow measurement is a unique success story since the beginning of the project. At the request of the German Massivumformung e.V., a sensor system for the reliable detection of spray quantities was developed. Of course, the partners of Massivumformung e.V. could rely on the innovative power of Jerko and now have the possibility to monitor their process even better. The sensor is suitable for all common forming lubricants - whether they contain oil or solids. Even non-Newtonian fluids are reliably detected. The sensor has a space-saving design and can be integrated into almost any spray system, even retrospectively. With the sensor you know even before the next forming operation whether the tool has been supplied with the required amount of lubricant and eliminate the resulting tool damage or consequential costs.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Mobile, compact and multifunctional. Whether as manual spraying equipment or on a fully automatic robot spraying system, the compact supply tank with its 45 litre stainless steel tank is suitable for all tasks. Equipped as standard with a pneumatic lifting device, handling is particularly easy. By using proven components, the sprayer is perfectly suited for continuous operation. The device is suitable for spraying lubricants or coatings with a high solid content. To change the tank or clean it, the complete tank cover with all attachments is lifted pneumatically.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Due to the variety of solutions we can supply you with a wide range of spray heads made to measure. Whether plate spray head, single nozzle spray head or a combination. With our know-how we develop your spray head that fits your requirements exactly.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

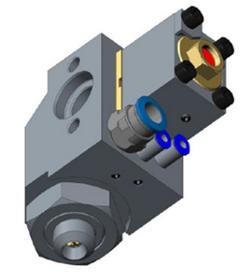

Our high pressure valves of the JB- series are specially designed for the metered spraying of liquids with a high proportion of solids. The completely dead space free construction leads the medium directly past the valve seat. Deposits and blockages, as known from many spraying systems, are a foreign word to us at Jerko. Compact design with low maintenance - these are the valves of the JB series! Pneumatically actuated, the valves achieve the shortest response times. 15 million switching cycles without repair have been confirmed by a customer. The best valves for spraying systems - already in use thousands of times!

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Compact and highly flexible. The spray valves as a compact combination of our nozzles with different spray patterns and the unrivalled valves of the JB series. The spray valves are perfectly suited for use with stationary nozzles such as forging rollers, cross wedge rollers or presses.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Developed to optimize the service life of warm forging presses with internal cooling of the work piece. Based on the extremely reliable high-pressure valves of the JB series, we have designed a completely dead space free valve block for internal tool cooling. High cross sections and an optimal atomization provide a powerful spray jet and increase the service life of your dies. Compact design, low maintenance and the modular system allow an easy conversion of your half-hot line. With our system, we have already been able to convert over 20 presses from outdated valve technology to modern spray mixing blocks. We have always been able to confirm the numerous advantages to our customers. Do you have problems with your spray system on a warm forging line? Then do not hesitate and contact us!

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

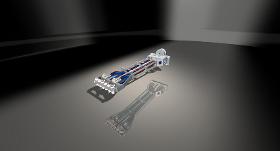

Pneumatic piston pump developed by Jerko. The pump is specially designed for spraying equipment to ensure a long service life and easy maintenance. This enables us to offer an unrivalled low price for spare parts. The necessary pressure to supply the spray equipment is generated by a piston pump developed by Jerko with a transmission ratio of 1:3.

Request for a quoteManufacturer/ Producer

Hooghe Weg 31

47906 Kempen - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

WILHELM KELLER GMBH & CO. KG

Germany

Ultra-compact and quiet pump series with low self-heating for run times up to 100% ED. The pump is self-priming up to approx. 6 meters.

Request for a quote

BÜRKLE GMBH

Germany

PumpMaster, canister and barrel pump for petrochemical liquids. The manual pressure pump is ideally suited for drawing off, decanting and emptying canisters and barrels. The hand pump is used to create excess pressure that forces the liquid out of the container. The stopcock also allows extraction of small quantities of liquid. The PumpMaster container pump is mounted on the container using a flexible stopper with a variable and adjustable diameter. No special thread adapters are required. PumpMaster fits all commercial container openings with a diameter from 46.5 mm to 60 mm. The immersion tube has a length of 95 cm and it can be shortened depending on the size of the container.

Request for a quote

KAMAT GMBH & CO. KG

Germany

customer-specific unit design incl. powerful high-pressure pump easy maintenance cavitation-free central drainage according to the latest global emission laws optionally fully automatic control own software with best support optional extreme sound absorption optionally all explosion protection classes

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free