- europages

- >

- Pumps

- >

- KAMAT GMBH & CO. KG

- >

- products

KAMAT GMBH & CO. KG

Germany

Manufacturer/ Producer

KAMAT GMBH & CO. KG

Germany

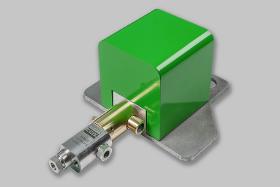

KAMAT foot valves and foot switches are products of the highest technical quality. They are designed for opening and closing the water supply to high pressure blasting equipment. This valve can be used to open and close the water supply to a high pressure blasting unit. The water is supplied by a high pressure hose connected to the foot valve. When the pedal of the valve is depressed, the valve opens. When the pedal is released, the valve closes and the water is discharged through the bypass without pressure. The foot valve and high pressure pump can also be connected via an electrical switch. If the pump has a suitable control, the pressure generation is switched on or off mechanically when the valve is actuated. The KAMAT foot valve has been designed and constructed in accordance with the rules of technology and applicable standards and guidelines.

Request for a quote

KAMAT GMBH & CO. KG

Germany

Multi-consumer valves distribute the output of the high-pressure pump evenly or as required to several high-pressure blasting tools. KAMAT offers two valves for this purpose: the mobile dual consumer control and the MVS4 multi-consumer control. When the consumer is opened, both controls open the valve and when the consumer is closed, the valve is closed. When all valves are closed, the controls switch off the pressure generation. The dual-user control is used to control one or two high-pressure consumers, such as high-pressure guns. The dual-user control is available with pneumatically or electrically controlled valves. The consumer and the high-pressure plunger pump have a corresponding control option. The dual consumer control and the consumer are connected by an electrical switch.

Request for a quote

KAMAT GMBH & CO. KG

Germany

The central idea of high pressure tools is to concentrate the energy of a high pressure water jet at the smallest possible point to maximise its effect. The smaller the area to be sprayed, the slower the process will be on large areas. The solution is to move the high pressure water jet quickly and systematically. Rotating joints allow the water to be transferred from fixed to rotating parts of the high pressure tool so that the water jet is moved in a targeted manner. KAMAT rotary joints are suitable for pressures up to 4,000 bar. They can be driven by internal or external energy and can reach up to 3,000 revolutions per minute. For fatigue-free and safe working, we also offer easy-to-use swivels for high pressure hoses, suitable for our high pressure pumps. Also designed and manufactured in-house, these swivels are internally streamlined to minimise flow restrictions.

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT's own filter technology is innovative and fast-growing. Why are we involved in filter technology? The answer is simple: high pressure cleaning technology using water as an environmentally friendly medium requires a high quality filter and recycling solution. In some cases, traditional filter manufacturers are unable to meet these requirements, which is why KAMAT also offers its own customer-specific solutions in the field of filter technology. High-pressure water cleaning technology has many advantages: A water jet can be used gently on the surfaces to be cleaned, water is generally available as a medium and at the same time is environmentally friendly without extensive delivery costs. When it comes to accessories, high pressure cleaning systems have special requirements that are difficult to meet. For this reason, KAMAT has developed its own customised high-pressure filter solutions. KAMAT high pressure filters are available for operating pressures up to 4,000 bar.

Request for a quote

KAMAT GMBH & CO. KG

Germany

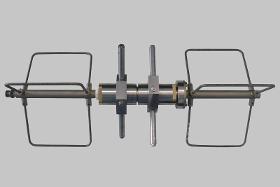

The nozzle consists of two counter-rotating nozzle housings into which the nozzle tubes are inserted with a connection for screw-in round jet nozzles. A special packing sealing system inside the nozzle housings ensures protection during operation and prevents the ingress of contaminants. In front of and behind the nozzle housings are spacers (basket system) to prevent the nozzle tubes from hitting the well wall. In addition, for best cleaning results, the temperature of the medium should be between 3 and 30°C.

Request for a quote

KAMAT GMBH & CO. KG

Germany

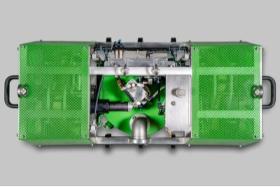

Our Surface Cleaner 3000 air is an extremely powerful high pressure cleaner. It is capable of cleaning at pressures of up to 3,000 bar. To make it even more efficient and smooth in operation, we have fitted it with pneumatically driven rotating nozzles. This ensures an even cleaning process at all times. A common application for our hp floor cleaner is the removal of rubber residue from airport runways. All our surface cleaners can be fitted with a vacuum. This ensures a trouble-free and dirt-free working environment, improves visibility and workplace safety and reduces the impact of the process on the environment.

Request for a quote

KAMAT GMBH & CO. KG

Germany

We have specially developed the KAMAT Gekko 350 in order to clean large steel surfaces, for example ships, or large tanks, rapidly and without building scaffolding. Key technical advantages of the high-pressure surface cleaner are the thought-out combination of natural magnets and chain drive, as well as controllable high-pressure nozzles. The complete high-pressure system is remotely controlled conveniently and safely.

Request for a quote