KB ROLLER TECH KOPIERWALZEN GMBH

Germany

Multi-Category

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

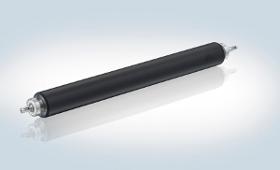

Requirements for products working in a high temperature fusing environment include continuously increasing requests for longer part life, higher print speed, and better print resolution involving ongoing material and process innovations. Our goal is to find the best combination of the following properties: Thermal resistance Thermal conductivity Abrasion resistance Anti-adhesive surfaces Elastomer hardness Substitution of Metal Substrates by Polyimide Belts Fusing by heat and pressure in digital printers has previously been realized with anti-adhesive coatings on aluminum or steel cores. These metal substrates have been increasingly replaced by seamless thin walled polyimide belts due to energy-saving environmental regulations and the growing requirement for “instant on” printing devices. Image Fusing Products Fuser rollers with soft and thin coatings more Fuser rollers for professional digital printing more Pressure rollers with solid silicone/PFA sleeves more Pressure rolle

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

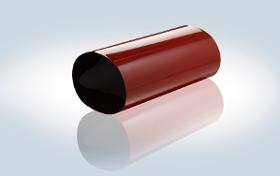

The requirements: highly precise tolerances without surface grinding extremely thin silicone coating layers (in picture: 0.6 mm) high silicone thermal conductivity (in picture: > 0.8 W/mK) anti-adhesive, thin top coatings (in picture: 30µm PFA)

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

The latest generation of color laser printers have four toning stations (CMYK). Paper passes all four stations in one cycle which enables higher print speeds. This design requires precise positioning of the belt with respect to the paper during the toning cycle. This need defines the properties of a seamless belt for a perfect printout: Perfect, defect-free surface Tight tolerances of diameter, length, width and surface roughness Precisely defined electrical conductivity over the entire belt surface KB RollerTech`s capabilities: Diameters: up to 1,000 mm Width: up to 600 mm Thickness: 50 - 100 µm (±10%) Electrical properties: 1E5 - 1E16 Ohm cm Roughness: < 1,0 Ra Primary and Transfer Charge Rollers Charge rollers are critical for long lasting, high quality printouts in laser printers and copiers. KB Roller Tech’s special compounds enable charge rollers to maintain continuously stable electrical properties. Primary charge rollers are mostly soft coated rollers with sensitive surf

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

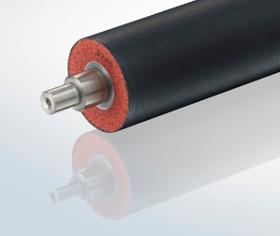

The requirements: long life (e.g. > 1 Mio A4) extremely thin elastomer coatings (e.g. < 1 mm) processing of high duty elastomers (e.g. fluoro-elastomers) high abrasion resistance non-stick top coatings (e.g. Teflon®)

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

Charge rollers are critical for long lasting, high quality printouts in laser printers and copiers. KB Roller Tech’s special compounds enable charge rollers to maintain continuously stable electrical properties. Primary charge rollers are mostly soft coated rollers with sensitive surfaces and precisely defined electrical properties. They are in contact with the photoconductor and transfer electrical charge in the nip area. The contact arc is created by the soft charge roller touching the hard coated photo-conductor drum. KB RollerTech`s capabilities: Length: < 354 mm Hardness: 45 - 72 Asker C Electrical properties: 1 ~ 10M Ohm (bei 500V/20°C ± 5)

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

The requirements: long life good thermal capacity of silicones non-stick top coatings precise tolerances for runout, diameter and coating thicknesses without surface grinding

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

Transport and drive rollers must provide precise transport of the print media in the digital printing process. This is especially true for wide format inkjet printers. Tracking lines, artifacts on the printout, or paper feeding failures are not accepted by the end-user. Our transport rollers are subject to the highest quality standards in respect to: Perfect, defect-free surfaces Precisely defined surface roughness High friction stability over life Tight tolerances in all dimensions

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

The requirements: homogenous and fine-pored cell structure tight tolerances of silicone foam density defined concave or convex surface shape non-stick top coatings (e.g. PFA sleeves) minimal odor through reduction of volatiles (VOC)

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

High speed professional printing machines use silicone oil in the fusing assembly for toner release and to add gloss to the printout. These systems can be found in color as well as monochrome printers. Besides environmental safety, the following properties are important: Thermal stability Tightly specified viscosity Very low volatile content Chemical purity Functionally designed (amino or mercapto modified) Roller Cleaning Agents Toner particles and paper dust accumulate on fuser rollers over time in toner-based printing processes,. This can result in image quality defects and shortened life of fusing components. Periodic cleaning with “Clean Protect” ensures a safe and thorough removal of any residue on the roller surface. Unlike alternative chemical cleaning substances, “Clean Protect” preserves sensitive roller surfaces, ensures defect-free printouts, and promotes longer fuser roller life. Our product is safe and effective. This cleaning solution is applied manually and has mini

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

For a few years now seamless polyimide belts have been used in toner fusing for desktop printers and multifunctional printers. The most important advantages compared to using traditional steel or aluminum cores are: significantly shorter times lead to reach run temperatures major improvements in energy efficiency weight-saving and lower logistic costs flexible belts enable higher print speed and resolutions by allowing a wider fusing nip for both b&w and color applications For these applications KB RollerTech developed a special coating process and produces seamless belts under clean room conditions. Different thermal and electrical properties of these belts can be precisely adjusted by adding special fillers. Today, the following dimensions are possible: Diameter: 20 - 310 mm Length: < 700 mm Wall thickness: 25 - 150 µm For the subsequent coating with anti-adhesive materials two alternative processes are used: Spray coatings with fluoro-polymers and subsequent sintering Coat

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

MICRON AMERICA

Turkey

TEP-3 is one of the most versatile economical machines in the market. So many advantages and a great low-price. This machine has been the best semi-professional hand press attaching machine for the past 20 years and still #1. Affordability Small and Practical No Maintenance Necessary Bench Mounted/Free Standing Suitable For Numerous Materials Heavy Duty Durability 1 Year Warranty Parts And Service Available Deep Throat Size 4 1/2"

Request for a quote

AXRO BÜROKOMMUNIKATION DISTRIBUTION IMPORT EXPORT GMBH

Germany

Canon Ink Cart. PGI-520BK for iP3600/4600/MP540/620/630/980 black (2932B001)

Request for a quote

AXRO BÜROKOMMUNIKATION DISTRIBUTION IMPORT EXPORT GMBH

Germany

Brother Toner TN-2420 for HL-L2310D/L2350DW/L2370DN/ L2375DW/DCP-L2510D/L2530DW/ L2550DN/MFC-L2710DN/L2710DW/ L2730DW/2750DW high capacity black

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free