KLN ULTRASCHALL AG

Germany

Manufacturer/ Producer

KLN ULTRASCHALL AG

Germany

In our laboratory we have all options to supply you with tests, parts analysis and pre- or small batches productions. Our team of highly skilled experts will assist you, if you have any question about how to design your parts for optimal welding. In our plant in Heppenheim we have the option to do welding tests with all the welding methods we offer in order to give you the maximum reliability for your serial process.

Request for a quote

KLN ULTRASCHALL AG

Germany

For the various contaminations KLN Ultraschall AG offers cleaning agents particularly for ultrasonic and spray-cleaning machines. If you have a problem with cleaning, please send us your parts. In our cleaning lab we will carry out trials to test which cleaning agent is most suitable for you. Below please see a list of some special cleaning agents. However, we have a much larger product range. • Ultrax 1.9 L • Ultrax 6.4 L • Ultrax 7.1 L • Ultrax 9.2 L • Ultrax 11.5 L • Ultrax 13.12 L • Ultrax 14.4 L Particularly for form cleaning we recommend for Aluminium forms: Ultrax 13.12L and Ultrax 7.1L Steel and cast molds: Ultrax 14.4L and Ultrax 7.1L

Request for a quote

KLN ULTRASCHALL AG

Germany

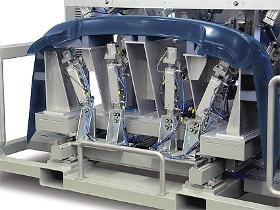

KLN develops and manufactures punching machines with precise curve design at the surface, for example to punch holes for the distance sensor holders or lamps in lacquered bumpers. Realisation of high-precision round or angled holes, but protection of the part; also suitable for already lacquered surfaces.

Request for a quote

KLN ULTRASCHALL AG

Germany

KLN Ultraschall AG offers cleaning for small and medium lot sizes without requirement to cleanliness with a max. part size of 300 x 350 mm and a max. weight of 20 kg.

Request for a quote

KLN ULTRASCHALL AG

Germany

KLN has created a machine series for precise parts cleaning with aqueous and organic cleaning agents. This series meets the requirements of the various industrial branches in the cleaning technology. Like in a modular construction system the components can be put together in any combination for a machine. This gives a maximum flexibility in the process technology. All process, automation and peripheral components for realization of cleaning, rinsing and drying are made in reliable KLN quality. We can offer you a complete automation for your individual requirements.

Request for a quote

KLN ULTRASCHALL AG

Germany

“Powersonic” is a type of KLN transducer systems with a particularly good cleaning effect and especially solid design. Transducer plates are ultrasonic transducers that can be flanged. The actual PZT transducer elements are fastened at the back of the sound-emitting transducer plate surface. Plates of different sizes and capacity can be used variably with various operating frequencies of 20, 25, 30, 40 or 132 kHz.

Request for a quote

KLN ULTRASCHALL AG

Germany

After cleaning we use drying systems in order to achieve spotless drying, to protect corrosion-sensitive parts or to avoid water intake into production. The drying systems can be integrated in manual or fully-automatic cleaning processes. KLN manufactures various drying systems in several versions.

Request for a quote

KLN ULTRASCHALL AG

Germany

KLN has developed spray unit concepts, e. g. for precision cleaning of electronic components, here focusing on cleaning of DCB, ceramics and polymer-FR4-SMD in inline continuous spray units. KLN plans and manufactures cleaning plants using state-of-the-art technologies. The machine concept is adapted to the referring chemical products used, thus safe monitoring and process control is guaranteed. The machines are made completely of stainless steel to achieve a high chemical resistance. Moreover, the machines can be used in a versatile way, they have an extremely sturdy and long-life design

Request for a quote

KLN ULTRASCHALL AG

Germany

The machine of series KT can be applied universally. It is designed for the industrial part cleaning. Application fields: metal degreasing, electrical industry, optical industry, medical technology, maintenance and service etc. The compact design of the machine as 3-tank system guarantees a high cleaning quality together with space-saving location. The basic version consists of a heated ultrasonic tank (tank 1) and heated cascade rinsing (tank 2 and 3). Additionally a separate dryer corresponding to the size of the compact unit can be made available. The tanks are incorporated in a solid frame. Optionally a stainless steel base frame can be delivered. Armatures, tank and frame are made of stainless steel. All valves can be easily operated at front of the machine. All electrical operating elements are on the front of the machine. They are each assigned to the tanks.

Request for a quote

KLN ULTRASCHALL AG

Germany

The riveting process creates irresolvable interlocking bonds. This is achieved by forming or reforming of thermoplastics. In most cases in this procedure only point-shaped or segmented joints are realized. In contrast to welding of two components there cannot be achieved hermetic joints. A particular version of this procedure is the bonding of plastics with metals, textiles and cardboard. The method is frequently used for wooden decoration parts, into which a chrome decoration strip has to be embedded. During the heating-up phase the hot air riveting does not get into contact with the material. A continous hot air flow heats up the riveting pin. Here the forming of the riveting head is carried out with a cold stamp in a separate station. By the cooling phase next in line a lower relaxation of the plastic material is achieved by pressure and mold constraint

Request for a quoteManufacturer/ Producer

Odenwaldstraße 8

64646 Heppenheim - Germany

europages also recommends

A selection of companies related to the activity:

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free