- europages

- >

- Laser - cutting and welding machines

- >

- MECHASYS GMBH

- >

- Laser Welding

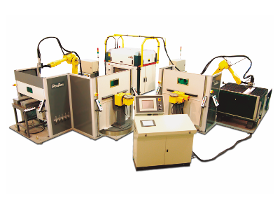

Laser Welding

Micro laser welding of single parts 300 x 500mm or in jig for mid range batches

Description

Laser welding is a very gentle welding technique, as the heat input takes place in a locally very limited area. In this way, it is possible to reliably connect critical components with one another in a materially bonded manner, without the parts annealing. With laser welding, the two welding partners are joined together with as few gaps as possible in order to then weld them together (e.g. press-fit zones such as EloPin® puzzled at any feed or distance). The background to this is that no additional material is generally used in laser welding. Exception for build-up welding or repair welding of e.g. broken tool parts such as punches or cutting plates or injection molding tools for abrasive plastics with glass fiber filling. Materials - almost all metals: e.g. • non-ferrous metals (Cu, CuSn0.15, CuSn6, CuNiSi, ...), • titanium, • steel, stainless steel (1.4301, 1.4404, ...), • spring steel (1.4310), • electrical steel (M235, M270, NO20, NO30, ...), …

- Laser - cutting and welding machines

- Mircro Welding

- assembly

- Precision

Similar products

IMS - INTEGRATED MECHANIZATION SOLUTIONS BV

Netherlands

At IMS, we combine the power of precision laser welding with our expertise in precision engineering. We do this to provide innovative and reliable solutions to weld microwires for the production of medical devices and medical implants.

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Pressing bearings Manually assemble anti-knock on hand lever press Automatically assemble and test retaining ring

Request for a quote

TRIBUNAS & FIGUEIREDO, LDA

Portugal

Mig-Mag TIG Laser Welding of carbon steel, stainless steel and aluminum.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc helps our customer to develop the laser welding automation system in Golf clubs manufacturing industry. Integrated with Fanuc robot system and Rofin laser, we provide a total solution for our customer both in laser welding and laser cutting. Industry 4.0 Intelligent manufacturing Full automation production Custom design for automotive industry

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free