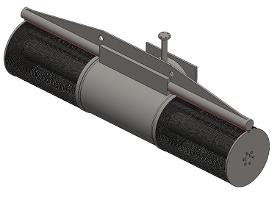

Looped Screen

The looped screen also called welded wedge wire consists of loops for filtration

Description

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. Advantages 1-Special surface treatment 2-Modular and customizable design 3-High durability 4-Suitable for heavy applications 5-Superior filtering with unique screen 6-Long service life & less maintenance Applications 1-Coal and Gold Mining Filtration 2-Mineral Processing 3-Water Treatment 4-Petrochemical Applications 5-Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

- Water treatment, industrial - systems and equipment

- Welded wedge wire

- Looped Screen

- Loop Wire Screen

Product characteristics

- Shape

- Looped/Flat

- Material

- Stainless Steel 304, 304L, 304HC, 316, 316L, 316Ti, 321 or depending on your request.

Documents

Videos

Similar products from ADVANCED ENGINEERING WEDGE WIRE

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. The main advantages of welded filter screen are Advantages Special surface treatment Modular and customizable design High durability Suitable for heavy applications Superior filtering with unique screen Long service life & less maintenance Looped wedge wire screen is adaptable for many applications including Applications Coal and Gold Mining Filtration Mineral Processing Water Treatment Petrochemical Applications Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with high efficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths. Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages 1-Special filtration 2-Counterbore and customized filtration holes 3-Corrosion resistance 4-High durability – long service life 5-Precisely drilled holes 6-Special surface treatment Applications 1-Sugar Pulp Pressing 2-Water Filtration 3-Paper Mills 4-Pressing 5-Processing of Chemicals 6-Seperation Process

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

Intake screen also called T-screen is used to intake and clear water in many industrial areas. They are commonly used in hydroelectric, agricultural, drinking applications to prevent dirty materials from the water. Intake screen is commonly used in lakes known as lake pump intake screen. Intake water works as passive intake screen to intake of water for generating electricity for hydropower. Water intake filter screens can intake clean water by eliminating unwanted materials. Because of its simple cleaning, major maintenance is not required for the operational time. Advantages: 1-High performance water filtration 2-Fish friendly 3-Corrosion resistance 4-Passive intaking water 5-High durability – less maintenance 6-Easy to install Applications: 1-Hydropower Intake 2-Lake Application 3-River Application 4-Water Cleaning

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The basket screen consists of cylindrical and tubular wedge wire screen which is suitable for centrifugal applications. Therefore, the conical or tubular shape of the screen basket helps the filtration process complete accurately. Centrifugal screen provides efficient filtration for unique applications with conical geometry. Advantages 1-Special surface treatment 2-Centrifugal customizable basket design 3-Corrosion resistance 4-Durable and long service life 5-Precise filtration 6-Strong mechanical properties Applications 1-Different applications are possible for the wedge wire screen basket such as vibratory centrifuge applications. 2-Mining Applications 3-Water Treatment 4-Chemical Fertilization 5-Food Processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote