- europages

- >

- Sensors

- >

- BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

- >

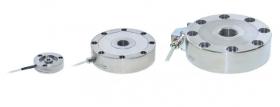

- Low-cost Tension and Compression Load Cell - 8427

Low-cost Tension and Compression Load Cell - 8427

Low-cost Tension compression load cell, canister, compact high - precision

Description

This low cost tension/compression load cell is an especially robust component, which can be easily integrated in a girder assembly between two cables or chains for measuring force. The standard model comes with internal thread, allowing any adapter parts, for instance eye brackets, to be fitted in the axis of symmetry. Alternatively, the optionally available adapters with external thread can be used for quick and easy screw-fitting into a threaded hole made for the purpose. The radial connection cable is extremely flexible and designed for a wide range of motion. In order to achieve the greatest possible stability for such a small sensor, making it suitable not only for the laboratory but also for industrial use, all parts have been welded together including the cable guide bush in the sensor housing. burster TEDS with an electronic sensor datasheet or standardization of the output signal in the sensor connecting cable are offered as options

- Sensors

- sensors

- load cell

- tension

Product characteristics

- Measuring range

- 0 ± 500 N + 0 ± 10 kN

- Direction of force

- tension/compression

- Standardization

- Option

- Protection class

- IP65

- Range of operating temperature

- -30 ... +80 °C

Documents

Similar products from BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The tension & compression load cells from the 8523 series are designed for a wide range of uses. The sensors feature many benefits, including three point-contact mounts for tilt-free installation. Thanks to this feature, excellent measurement results can be achieved even with a sub-optimum mounting surface. The force to be measured is applied to the central threaded hole in the tension or compression direction. For measuring purely compressive loads, using load buttons from our accessories range saves the need for complex sensor-integration mechanisms. Tensile loads in rods or chains can also be detected with ease using the optional pull plate. Inside the sensor is an elastic membrane, on which are applied strain gages connected in a full Wheatstone bridge. FEATURES Measuring ranges from 0 ... 20 N to 0 ... 5 kN Tilt-free installation thanks to point-contact mounts Excellent price/performance ratio Easy mounting burster TEDS optionally available

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Thanks to its compact shape and three fixing holes on its underside, the 8526 compression load cell can be used in a variety of applications. With its wide choice of measuring ranges from 0 ... 100 N up to 0 ... 1 MN, it really can cover a wealth of measurement tasks, from the laboratory to use in heavy industry. The integral load button provides an easy and reliable means of applying the force to be measured. Angle errors in the load application with a deviation from the measurement axis of up to 3° have only a minor influence on the measurement signal. For ideal measurement accuracy, the load cell should be mounted on a surface that has been ground and has a hardness of at least 60 HRC. The model 8526 load cell is designed with an internal elastic membrane, to which strain gages are attached. When a compressive load is applied to the load cell, the membrane is elastically deformed and transfers its tension to the strain gages.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 8524 precision tension & compression load cell is a versatile sensor for highly accurate load measurements in diverse applications. Optimum measurement quality is achieved with the load cell mounted on a flat, hard and polished contact surface. This requirement does not apply to small measurement ranges of up to 0 ... 2 kN because three knife-edge bearings ensure that the sensor is seated securely. Our brochure „Load Cells“ explains how you can design parasitic loads out of your mechanical system. Through-holes in the outer flange are used for fastening the 8524 sensor to the system structure. The load is applied via the central blind threaded hole or optionally via a load button. Alternatively, a pull plate and even rod end bearings, if desired, can be attached to the sensor for equally easy measurement of purely tensile loads, for instance in Bowden cables or chains. The 8524 sensor is designed to measure static, quasi-static and dynamic compressive and/or tensile loads.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The measuring element of the load cell consists of a double bending beam on which strain gages are applied. The applied force detunes the measuring bridge so that a proportional output voltage is generated. The strain gages on the measuring element are protected against dirt and water spray by a rubber bellows. The sensor can be easily mounted via two mounting holes. The tension or compression force to be measured is introduced at the opposite end perpendicular to the sensor axis. Due to its special design, the influence by an extension (e.g. touch finger) on the measuring signal is low. Overload protection can be realized with little effort using a mechanical stop. FEATURES For tension and compression forces Measuring ranges from 0 ... 5 N to 0 ... 2 kN Relative non-linearity: ≤ ±0.1 % F.S. Very low mounting height Simple force application Material aluminium or stainless steel Special design on request burster TEDS optionally available

Request for a quote