MAHLO GMBH & CO. KG - MEASUREMENT & CONTROL FOR CONTINUOUS WEB PROCESSES

Germany

Manufacturer/ Producer

MAHLO GMBH & CO. KG

Germany

Control of thread density / course density / basis weight The Famacont PMC determines the thread density by means of a non-contacting, optoelectronic or imaging process. With the optoelectronic process individual threads or courses pass the sensor and are projected onto the photocell using a precision optical lens. The resulting frequency is proportional to the thread count. A high-resolution camera is used with the imaging process. The image is analysed with using suitable software (FFT analysis). Both, the thread count in weft and warp direction can be determined here with maximum precision.

Request for a quote

MAHLO GMBH & CO. KG

Germany

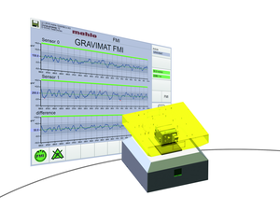

Transmission of beta rays The weight monitoring and control system measures the weight continuously, without contact, destruction-free and on moving product. The measurement is based on the attenuation of rays from a radioactive isotope through the substrate located in the measuring gap. This attenuation in intensity is an indication of the weight of the product.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Reflexion of infrared light Automatic width measurement on a running product web. IR LEDs used in reflective mode continuously and precisely determine the product width. The sensor module only needs to be attached on one side of the product. The compact design allows it to be installed even in the tightest mounting spaces. Retrofitting is possible virtually anywhere.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Condensate temperature control The Atmoset SMT regulates the residual moisture of the tissue with steam-heated cylinder dryers. The deviation of the condensate temperature from a preset setpoint is used to directly calculate the amount of energy required for drying. The heating output is optimised according to the product. The Atmoset SMT enables a stable and effective drying process. The optimal degree of drying is always reached, regardless of the weight of the product or the web speed.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Ionisation of the air The Antistat AMW ioniser for trouble-free processing of synthetic materials and of textiles with high charge separation. By ionising the ambient air, the electrostatic charge is diverted from the product sheet. Antistat AMW can be used at high or low speeds.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Measurement of steam Much unused energy is wasted through the exhaust air during drying processes without appropriate control. The Ecomat AML optimises the heating energy required by monitoring charging of the exhaust air with water steam and controls this factor through the fan speed or the exhaust air vent control.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Infrared pyrometer The Thermosense HP270 is used for non-contacting temperature measurement in driers and stenters and records the temperature of running product webs. The sensor is temperature-resistant up to 270 °C. It can therefore be mounted inside driers.

Request for a quote

MAHLO GMBH & CO. KG

Germany

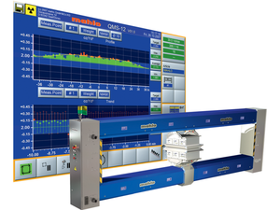

Web process control The Qualiscan QMS is a modular system for measuring, logging and controlling critical process parameters over the entire width of the product, including basis weight, coating weight, thickness, moisture etc.

Request for a quote

MAHLO GMBH & CO. KG

Germany

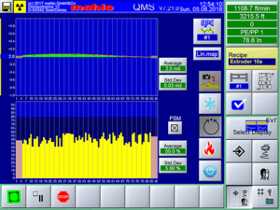

Automatic control of thermal diebolts of extrusion dies The DieControl APC Pro automatically controls thermal bolts of extrusion dies according to the earlier measured cross-section profile of the material. This results in uniformly thick films, sheets or coatings even with fluctuations in the feed, material change or when starting the system. The automatic control and the extrusion close to the set point also achieve considerable material savings and quality improvement.

Request for a quote

MAHLO GMBH & CO. KG

Germany

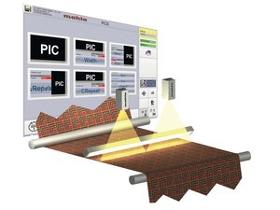

Pattern and distortion control The leading pattern detection system using camera technology. The repetitions of printed, woven or tufted patterns are evaluated according to certain algorithms and are used for measuring, correcting and evaluating distortions and patterns. The system uses one or two cameras, depending on the width of the product, to detect the position of the pattern and automatically and continuously determine the pattern repeat, as well as the product width, and together with a straightening machine align the product distortion based on the recognized pattern.

Request for a quoteManufacturer/ Producer

12 Donaustr.

93342 Saal - Germany