AYBERKSAN PLASTIK KALIP SANAYI - Injection moulding of rubber and plastic industry : Injection mold, Plastic mould, Plastic injection

Turkey

Manufacturer/ Producer

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Although mold production is widespread in the Plastic Mold sector, the necessary care is not taken in mold manufacturing. It is extremely wrong to expect high efficiency from the mold, which started to be produced only in line with customer demand, without the necessary tests and analysis. For the product to be mass-produced, it is essential to carry out some tests and cost and efficiency analyzes before the production starts. For this reason, as AYBERKSAN Mold Industry, we provide consultancy services to our customers in many areas.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Injection mold production is a complex process that cannot be underestimated. The resulting product is the main element to be used in injection molding machines. Therefore, at every stage of the process, there are improvements that need to be made in line with the research and the data obtained from these researches. The R&D process, which started with the examination of the samples we received, continues at the design and injection stages. As AYBERKSAN, our aim is not to present a large number of products with the existing data, but rather to increase the data we have and to present better quality, problem-free and economical solutions. The process we call development cannot happen without research. With this awareness, we, as AYBERKSAN Kalıp Sanayi, continue our research to take the experience we have gained so far to the next level, to add a new one and to develop it.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

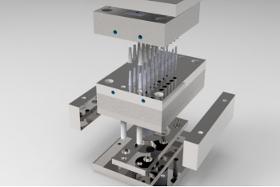

Injection Mold design is a process that starts with sketches on paper, continues with computer programs and ends with necessary improvements after injection. Of course, today, design on paper is almost non-existent, except for the way customers express themselves. With the developing technology, 3D designs made with computer programs have provided a great deal of convenience. As AYBERKSAN Kalıp Sanayi, we start production in line with the demands of our customers, after making the most suitable designs for them and getting their approval. Although design has become easier with technology, it is a difficult process due to factors such as surface quality, type of raw material and the machine to which the molds will be attached. In order to ensure that the product to be produced is at the desired efficiency, the mold design is tested and analyzed many times in programs such as Moldflow, CAD and CAE, and the necessary data is obtained.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Plastic Mold Industry Sector; It has developed with the widespread use of plastic. Our company, which closely follows these developments, has made many improvements and updates in the field of plastic mold / injection mold. By directing the design process, which is completed with great care, to the machine park, the necessary mold set for mold manufacturing is ordered. The raw material of the incoming mold set is selected according to the product and production type. Quality and efficiency are kept at optimum level in works that require high precision. In addition to injection molds within AYBERKSAN Plastic Mold Industry; ZPL, hot runner, blow mold, rubber press mold and insert mold are also produced. The mold designed in the CAM phase is programmed to be processed on CNC machines. At the same time, processes that require dimensional precision are reviewed. After programming, the mold is processed on the CNC machine.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

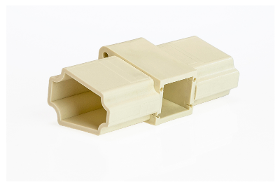

Most of the plastic products are produced by injection method. Injection in summary; It is the process of injecting the melted raw material into the mold at a certain temperature and proportion and obtaining the plastic product after it cools. It is a method widely used in Turkey and in the world. As AYBERSAN Plastik Kalıp Sanayi, we also house the plastic injection process, which is an indispensable part of our injection mold production, within our company. Plastic injection; raw material amount, machine temperature, runner temperature, cooling time etc. It is a process that includes many factors at the same time. If it is not done by experts, there may be burrs, depressions, bursts, etc. in the product. undesirable consequences are inevitable. Our company, which sees quality and satisfaction as equivalent, has made and continues to make all necessary investments in this regard.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

The first formation of the Turkish Defense Industry in History dates back to the 14th century. Our Defense Industry, which was in a strong position until the 17th century, lost its power after the 1st World War and we were left out of the developments in Europe in the 18th century. II. The activities in the field of defense industry, which started in the first years of the Republic period after the World War II, became foreign-dependent with the aid received from the USA due to the economic situation and political reasons. Concrete steps were taken to establish the National Defense Industry in the 1970s. With the development plans initiated in the 1980s and the establishment of the Undersecretariat of Defense Industry, necessary steps were taken to nationalize the weapons and equipment used. Our national defense industry has mobilized many sectors in parallel with the recent developments. One of the most important of these is the injection mold industry.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

One of the indispensable elements of the health field is the medical sector. Many devices, equipment, machines and test kits used in this sector have become indispensable elements in terms of quality health care. The importance of domestic entrepreneurs is very great in this sector, where we are 80% dependent on foreign sources. The fact that any investment to be made will reduce our country's dependence on foreign health in the field of health and play a major role in gaining strength in the economic and social field cannot be ignored. As AYBERKSAN Plastik Kalıp Sanayi, we know the importance of being in the medical sector and we are directing our investments in this direction. We respond to the needs of the medical sector with the production of molds and plastic injections for the needs in the pandemic period, test kits with sensitive content, and devices used in disease treatments.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

One of the most popular sectors in the field of Injection Molding and Plastic Injection is the Automotive Sector. In general, the majority of automotive accessories consist of plastic and rubber. This is the most important indicator that injection molds and plastic injection products maintain their value. The markets formed in the global world have almost taken on the nature of domestic markets, and competition between countries has gained momentum. AYBERKSAN Plastic Mold Industry takes the necessary steps one by one, with quality and corporate awareness, for its goals to become a brand in both local and world markets.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Furniture, which is defined as objects that facilitate living conditions and provide order in the space; It has created its own industry that has been constantly evolving throughout history. With the development of technology, competition in the furniture industry has increased and labor has become cheaper. The most important elements in modern furniture have been the use of materials, lightness and sustainability. Therefore, it has become an indispensable part of the plastic furniture industry. As AYBERKSAN Kalıp Sanayi, we have taken part in the sector by producing molds for a large number of equipment, accessories and plastic parts of moving parts used in the furniture sector. Our products come to the fore with the most suitable materials and design quality.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Drilling works in our country started with the establishment of MTA in 1935. With the 1950s, drilling applications started not only in the field of oil extraction, but also in the field of mining and natural resources. After the 1970s, the number of private drilling companies has increased and today it is over 1000. With the development of the drilling industry, the use of plastic injection products has increased. The parts, which are mostly called plastic gaskets and felts, are produced and used as plastic injection. Molds of gaskets made of rubber are also produced within our company and product prints are taken. Rubber and plastic seals etc. belonging to the equipment used in this sector. As AYBERKSAN Kalıp Sanayi, we bring the products together with the end user.

Request for a quoteManufacturer/ Producer

Ivedik OSB 1535 cad. No:40

06378 Ankara - Turkey